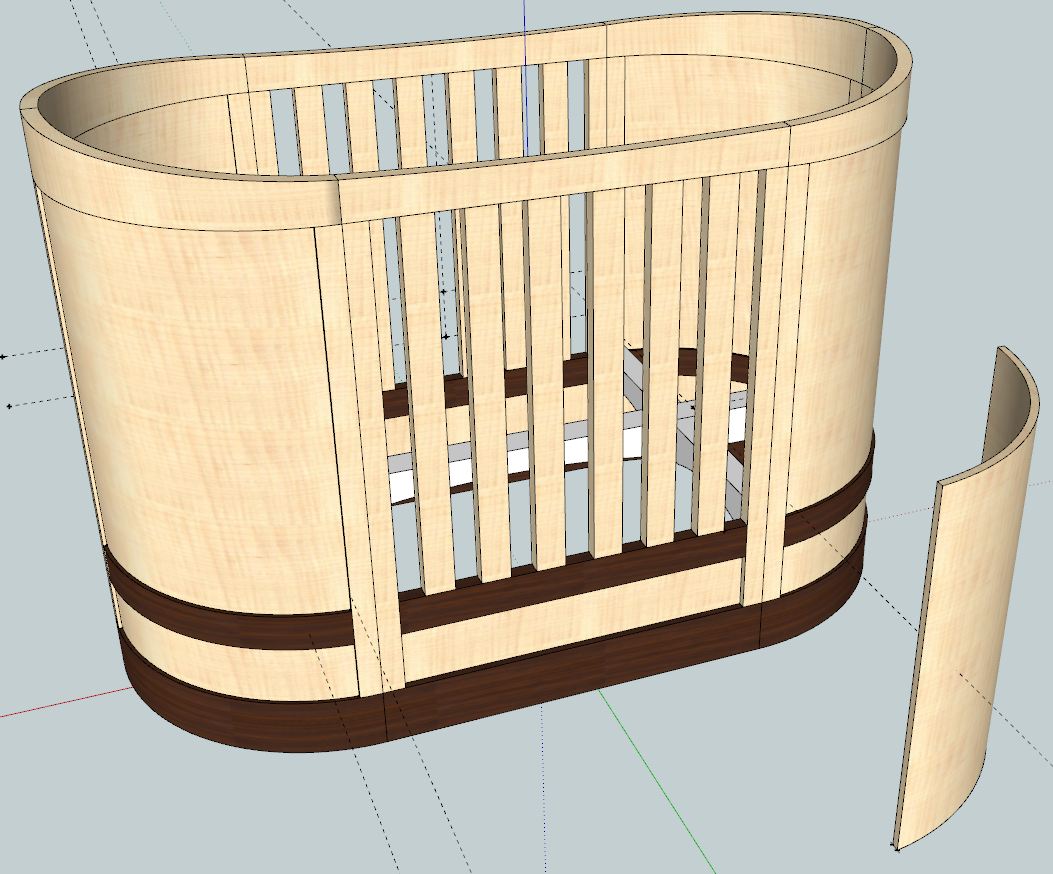

I've got to make up a bunch of curved plywood panels for a crib project, and I've been dithering about the type of plywood to use. I'd originally planned to use 3 layers of 3mm plywood with 2 layers of 1.5mm maple veneer on the outside. This would give me a panel 12mm thick, which is about where I want it to be.

I've been doing some practice bends for other parts of the crib however, and I'm starting to get concerned about springback if I go with my original plan. I thought that I might want to try flexy ply, but I notice that the thinnest it comes in is 5mm.

If I still want to aim for around the 12mm mark for panel thickness, that would mean I could only use 2 layers of flexy ply, sandwiched between the 1.5mm maple veneer (13mm total)

Does anyone use flexy ply that could advise me on how stable/rigid a panel like that would be?

Radius will be around 15", with the panel being around 22" wide by 27" tall

I've been doing some practice bends for other parts of the crib however, and I'm starting to get concerned about springback if I go with my original plan. I thought that I might want to try flexy ply, but I notice that the thinnest it comes in is 5mm.

If I still want to aim for around the 12mm mark for panel thickness, that would mean I could only use 2 layers of flexy ply, sandwiched between the 1.5mm maple veneer (13mm total)

Does anyone use flexy ply that could advise me on how stable/rigid a panel like that would be?

Radius will be around 15", with the panel being around 22" wide by 27" tall