Beardo16

Established Member

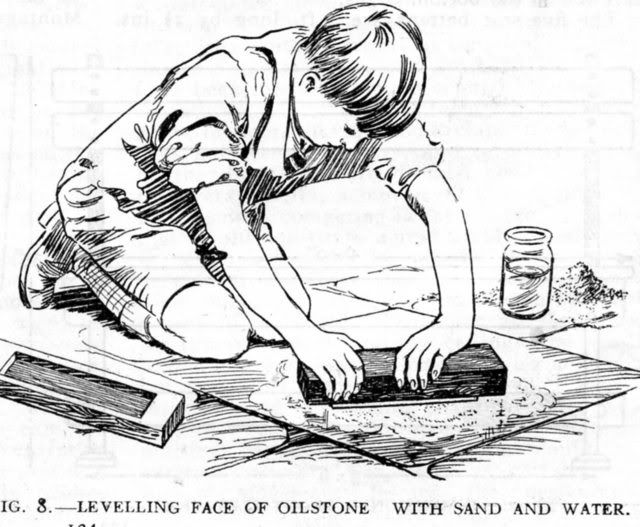

Anyone know how to flatten a waterstone without the use of a lapping plate/stone?

I recently bought the stones but noticed yesterday they are not flat so this is the reason.

Also anyone know why the jet wetstone grinder doesnt come with the diamond trueing stone to flatten the wetstone. Seems real odd as thats another 40 quid to flatten the wetstone. :evil:

Thanks

I recently bought the stones but noticed yesterday they are not flat so this is the reason.

Also anyone know why the jet wetstone grinder doesnt come with the diamond trueing stone to flatten the wetstone. Seems real odd as thats another 40 quid to flatten the wetstone. :evil:

Thanks