RossJarvis

Established Member

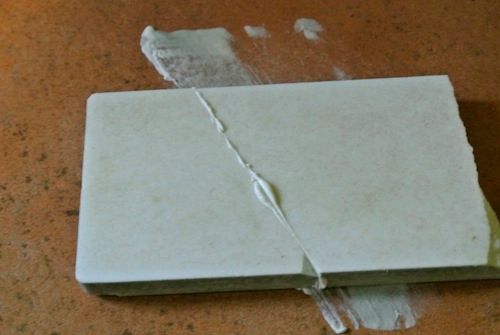

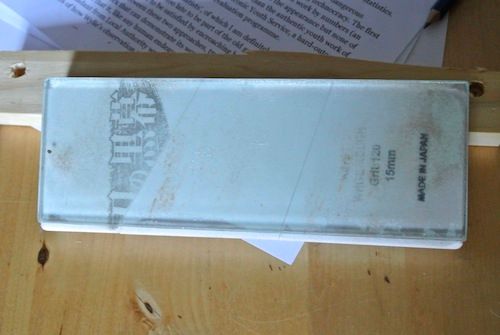

Any of you who are foolish enough to read my other posts may be aware that I managed to break a brand new 35 GBQuid Japanese Whetstone, due to not turning a light on in the larder;

Due to the crumbling on the edges, I thought I wouldn’t even be able to glue it back together;

…many “boo hoo hoos” later and a bit of web-looking and following some great advice from a couple of guys on here (ta Grayorm, Pete and Den), I thought I might be able to salvage it. First thing to do was grind the broken edges, here I’m using a concrete paver, left over from the new path and a bit of 2x2 to hold it square;

…to do the next bit I made a guide to hold the next piece at the reverse angle to the first bit;

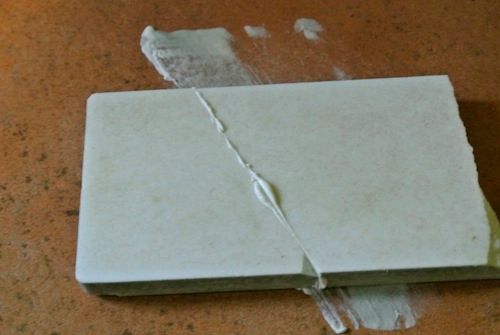

…and then I “lapped” the ground edges together for a good fit and to correct any angles between them, I was using a contoured tile I found in the garden, possibly a flat one or some glass would be better;

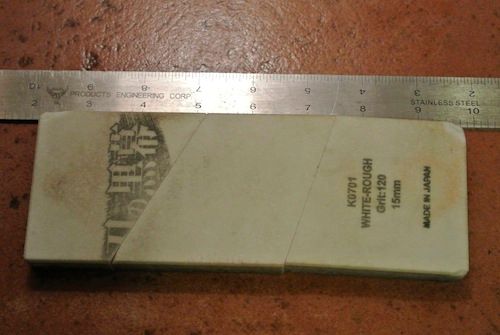

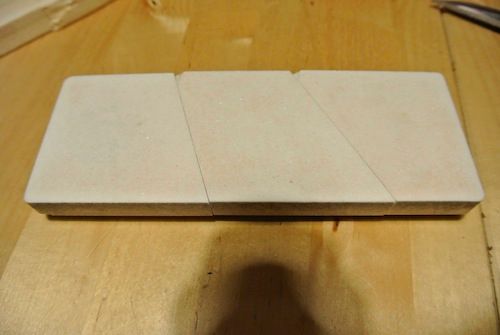

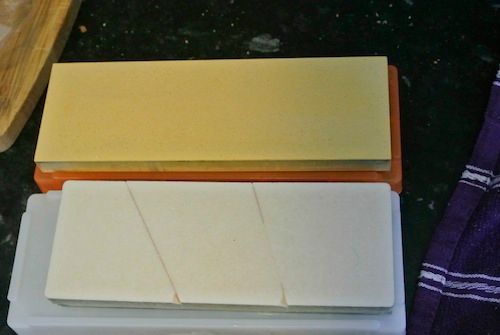

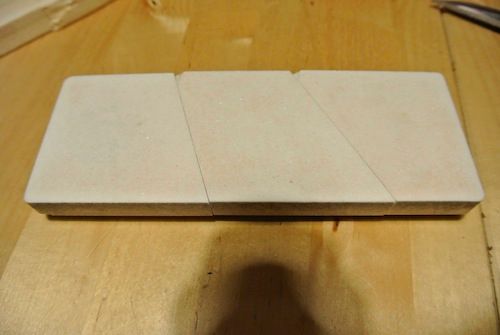

I wish I’d kept the sludge, as I could have mixed this with glue to fill some gaps! I was left with three regular, non wobbly bits of whetstone;

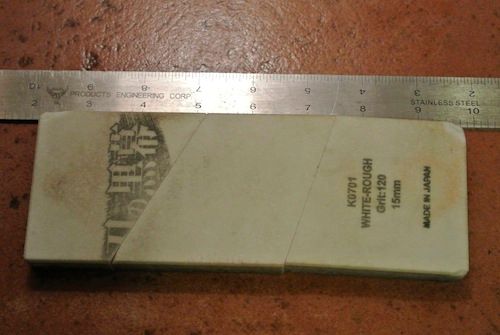

Not 100% straight but good enough for government work at least;

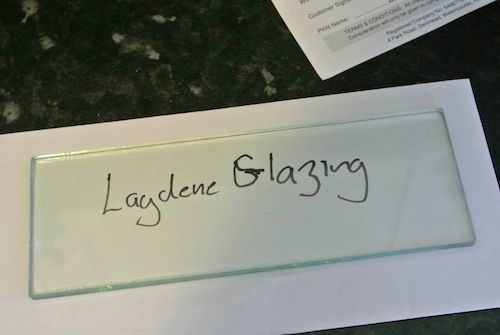

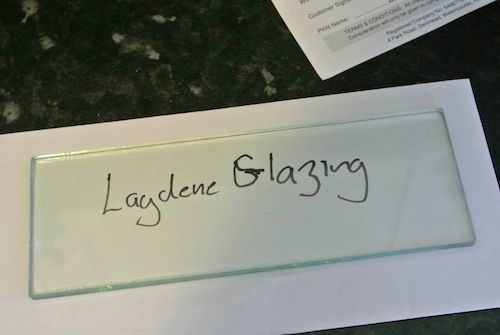

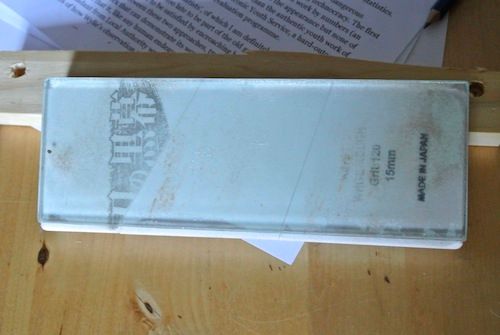

I left these long enough to dry out and the next day I phoned the local glaziers, who had moved, so are no longer local and within 6 hrs I got delivered a cut to size, ground edged, piece of 6mm laminate glass. This was a fiver so I recommend these guys well. I was so chuffed with the service I gave the driver a 2 pound note for his efforts;

Next I got to the repairing bit. 1 packet Hobnobs, ¾ pint tea, two tubes of Araldite normal (found in spare room), some plastic card stuff, glass and the bits of stone.

araldite was mixed, spread on the glass and on the lower sides of the joining edges;

…all the bits were assembled;

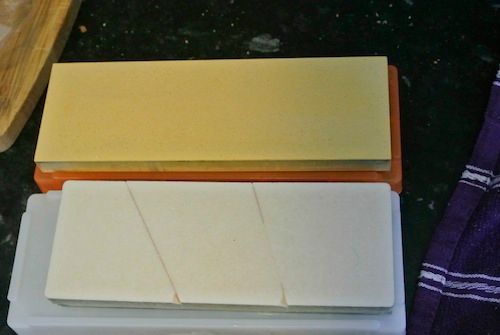

and the flattening stone was re-deployed to weigh it all down;

I found I couldn’t put pressure on the ends of the stone to hold the joints together. Being wedge shaped, they just slid sideways. I think something rigid on either side would be needed, but as I wasn’t sure if this was normal or rapid Araldite, I didn’t want to hang around to work it out. Come the morning, everything was looking okay;

I could see the top surface was a little off true and a bit of glue had squirged out the gap;

so I took it outside to the “flattening station” and it all came right;

It’s a wee bit shorter than it was, but still very much a usable size;

To see if it was up to scratch I took an unfettled plane iron to it (here I’m grinding by hand, rest assured I did it properly later, hee hee hee!)

…and I can safely say it works just as well as it did before I dropped it. I am also very pleased that spending a fiver saved me having to get a new one.

Due to the crumbling on the edges, I thought I wouldn’t even be able to glue it back together;

…many “boo hoo hoos” later and a bit of web-looking and following some great advice from a couple of guys on here (ta Grayorm, Pete and Den), I thought I might be able to salvage it. First thing to do was grind the broken edges, here I’m using a concrete paver, left over from the new path and a bit of 2x2 to hold it square;

…to do the next bit I made a guide to hold the next piece at the reverse angle to the first bit;

…and then I “lapped” the ground edges together for a good fit and to correct any angles between them, I was using a contoured tile I found in the garden, possibly a flat one or some glass would be better;

I wish I’d kept the sludge, as I could have mixed this with glue to fill some gaps! I was left with three regular, non wobbly bits of whetstone;

Not 100% straight but good enough for government work at least;

I left these long enough to dry out and the next day I phoned the local glaziers, who had moved, so are no longer local and within 6 hrs I got delivered a cut to size, ground edged, piece of 6mm laminate glass. This was a fiver so I recommend these guys well. I was so chuffed with the service I gave the driver a 2 pound note for his efforts;

Next I got to the repairing bit. 1 packet Hobnobs, ¾ pint tea, two tubes of Araldite normal (found in spare room), some plastic card stuff, glass and the bits of stone.

araldite was mixed, spread on the glass and on the lower sides of the joining edges;

…all the bits were assembled;

and the flattening stone was re-deployed to weigh it all down;

I found I couldn’t put pressure on the ends of the stone to hold the joints together. Being wedge shaped, they just slid sideways. I think something rigid on either side would be needed, but as I wasn’t sure if this was normal or rapid Araldite, I didn’t want to hang around to work it out. Come the morning, everything was looking okay;

I could see the top surface was a little off true and a bit of glue had squirged out the gap;

so I took it outside to the “flattening station” and it all came right;

It’s a wee bit shorter than it was, but still very much a usable size;

To see if it was up to scratch I took an unfettled plane iron to it (here I’m grinding by hand, rest assured I did it properly later, hee hee hee!)

…and I can safely say it works just as well as it did before I dropped it. I am also very pleased that spending a fiver saved me having to get a new one.