You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fitted my DRO

- Thread starter seaco

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

nathandavies

Established Member

that looks lovely, loads of metal, loads of shed, and loads of wires. what does it do?

porker

Established Member

Hi Lee,

How did you find the fitting? It looks like a SINO DRO? I have been considering this for my Bridgeport for some time although as I have decided to move house I will probably postpone until the workshop is moved. These appear to be excellent value for money and certainly look the business. I have had enough of reading the imperial dials, accommodating backlash and converting to metric when required.

Be interested to hear how it has improved using the machine and your general impressions

cheers

Matt

How did you find the fitting? It looks like a SINO DRO? I have been considering this for my Bridgeport for some time although as I have decided to move house I will probably postpone until the workshop is moved. These appear to be excellent value for money and certainly look the business. I have had enough of reading the imperial dials, accommodating backlash and converting to metric when required.

Be interested to hear how it has improved using the machine and your general impressions

cheers

Matt

Lons

Established Member

nathandavies":1s3wi66e said:that looks lovely, loads of metal, loads of shed, and loads of wires. what does it do?

Me too? :?

Took the words out of my mouth.

Bob

porker

Established Member

What does it do?

Digital Read Out

Measures X,Y and Z travel down to less than a thou. Works on glass scales fixed to the axis of the mill and generally makes life easier as machine wear and backlash are effectively compensated for.

HTH

Digital Read Out

Measures X,Y and Z travel down to less than a thou. Works on glass scales fixed to the axis of the mill and generally makes life easier as machine wear and backlash are effectively compensated for.

HTH

£24.99

Facemoon Reusable Masks,Safety Masks,Dual Filter Masks, Paint, Dust, Epoxy Resin, Construction, Welding, Sanding, Woodworking, Chemical Reusable Gas Masks

ShenZHEN CIRY MINGYANG LITIAN ELECTRONIC ECOMMERCE

£17.99 (£1.80 / count)

£27.44 (£2.74 / count)

3M 8822 Disposable-fine dust mask FFP2 (10-pack)

Amazon.co.uk

£238.91

£360.17

Trend Portable Benchtop Router Table with Robust Construction for Workshop & Site Use, 240V, CRT/MK3

Amazon.co.uk

£12.50 (£1,250.00 / kg)

£14.45 (£1,445.00 / kg)

JSP M632 FFP3moulded Disposable Dustmask (Box of 10) One Size suitable for Construction, DIY, Industrial, Sanding, dust protection 99 Percent particle filtration Conforms and Complies to EN 149

Amazon.co.uk

Myfordman

AKA 9Fingers

Lee,

Have you lost any Y axis travel due to the X scale? Mine is mounted on the front of my table to avoid any loss.

Essentially the same machine as yours -a VMC from Myford - who else LOL

MM

Have you lost any Y axis travel due to the X scale? Mine is mounted on the front of my table to avoid any loss.

Essentially the same machine as yours -a VMC from Myford - who else LOL

MM

nathandavies

Established Member

how much does such a thing cost?

You won't regret it, I've had them on my mill for about 2 years now and would not go back to a machine without them.

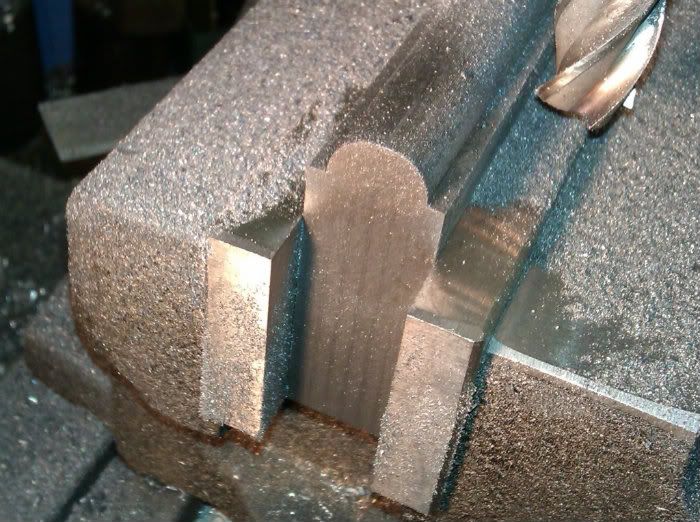

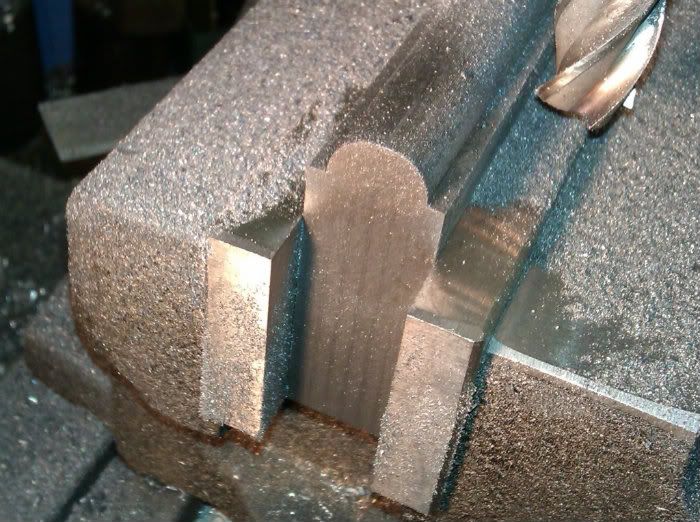

No only will they give an accurate position of the workpiece to 0.0002" they have hand functions like PCD which will equally space any given number of holes around a circle or arc. Place a given number of holes equally along a given length and direction of line and if you can understand the instruction book allow you to use standard cutters to machine curves like this profile.

No only will they give an accurate position of the workpiece to 0.0002" they have hand functions like PCD which will equally space any given number of holes around a circle or arc. Place a given number of holes equally along a given length and direction of line and if you can understand the instruction book allow you to use standard cutters to machine curves like this profile.

Rod/Bob as Porker says really they are scales for reading the X,Y and Z and Rod the make is Denford although they have different badges put on them also called a VMC or 626 I think Grizzly and Myford do virtually the same mill..

Matt the make of mine is Sinpo but yes they all seem to be the same DRO systems again with different badges, fitting was straightforward although slow as I hadn't done one before, the Z axis (the knee) was the hardest as the scale has to be square in both axis and as you can see in the pics the mills column is tapered so that took me a whole day to sort, but I must say it's brilliant and worth every penny and you wont be disappointed!

Myfordman since I have taken the pic I have reduced the depth of the guard on the X axis by about 10mm which has helped, I have a bellows type guard on the ways and this limits the Y axis a little already and I've measured it at about another 5mm loss, I can live with this as I can keep the length guides at the front of the table and anything big on the mill I can always pull the head forward for more room...

Matt the make of mine is Sinpo but yes they all seem to be the same DRO systems again with different badges, fitting was straightforward although slow as I hadn't done one before, the Z axis (the knee) was the hardest as the scale has to be square in both axis and as you can see in the pics the mills column is tapered so that took me a whole day to sort, but I must say it's brilliant and worth every penny and you wont be disappointed!

Myfordman since I have taken the pic I have reduced the depth of the guard on the X axis by about 10mm which has helped, I have a bellows type guard on the ways and this limits the Y axis a little already and I've measured it at about another 5mm loss, I can live with this as I can keep the length guides at the front of the table and anything big on the mill I can always pull the head forward for more room...

Lons

Established Member

Ah right!

My neighbour made his own for his Myford machine, but then he was an electronics engineer, worked for RS for a while. sadly with us no longer.

Bob

My neighbour made his own for his Myford machine, but then he was an electronics engineer, worked for RS for a while. sadly with us no longer.

Bob

paultnl

Established Member

I think a Raspberry Pi and a bit of tinkering could soon beat the £369 price.

porker

Established Member

There are a load of people who have pulled apart cheap digital callipers and wired them through an Arduino or RaspPi or similar but you still need the scales and display and to get scales long enough for this size mill the cost is pretty good.

Metal_Gazza

Established Member

Nice job... Any problems with coolant or swarf messing up the scales?

Similar threads

- Replies

- 29

- Views

- 1K