Kalimna

Established Member

- Joined

- 18 Nov 2009

- Messages

- 1,275

- Reaction score

- 1

Greetings,

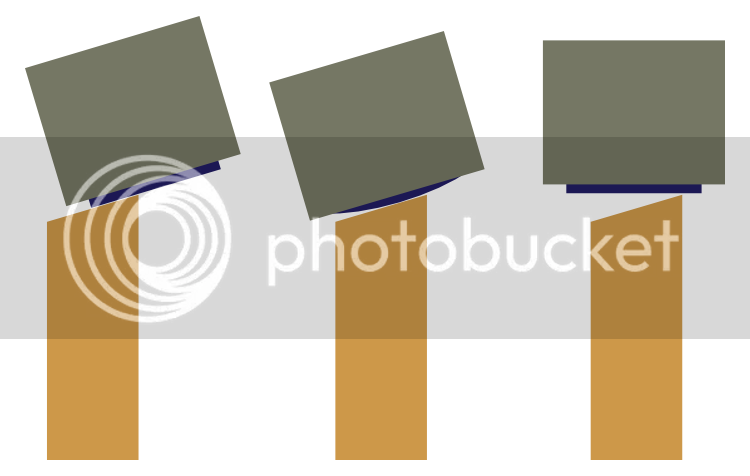

Having recently taken delivery of a jig that simplifies the honing of a camber on a blade (for me at any rate, this isnt meant to be a jig vs handheld question), and put a nice gentle camber on a couple of blades, I have a query regarding said blades.

Apologies if this is as daft a newbie question as it sounds in my head, but what is the suggested technique for squaring up an edge with one?

With the flat blades, I just did sequential shavings to square up an edge, which took me a bit of time, but got there in the end. However, using the cambered blade, it seems that I am getting very large swings in off-squareness from one edge to the other with this technique. I still seem to get there in the end, but lose a significant portion of board width doing so.

Having said that, track-free surfaces when smoothing are rather wonderful. I may not need so much sandpaper now

Thanks for any help offered,

Adam

Having recently taken delivery of a jig that simplifies the honing of a camber on a blade (for me at any rate, this isnt meant to be a jig vs handheld question), and put a nice gentle camber on a couple of blades, I have a query regarding said blades.

Apologies if this is as daft a newbie question as it sounds in my head, but what is the suggested technique for squaring up an edge with one?

With the flat blades, I just did sequential shavings to square up an edge, which took me a bit of time, but got there in the end. However, using the cambered blade, it seems that I am getting very large swings in off-squareness from one edge to the other with this technique. I still seem to get there in the end, but lose a significant portion of board width doing so.

Having said that, track-free surfaces when smoothing are rather wonderful. I may not need so much sandpaper now

Thanks for any help offered,

Adam