My old 1/4" b&q £20 router just isn't cutting it any more, in fact it's cutting more of my hand where half of the plastic grip has fallen off.

Having read a lot of threads, I now fancy one of these two routers, but not sure if these large 1/2" jobbies will be usable for hand held use. I don't have a table (never used one), but plan to at some point.

I will use it mostly for speaker cabinet building.

- Suitable for hand held use?

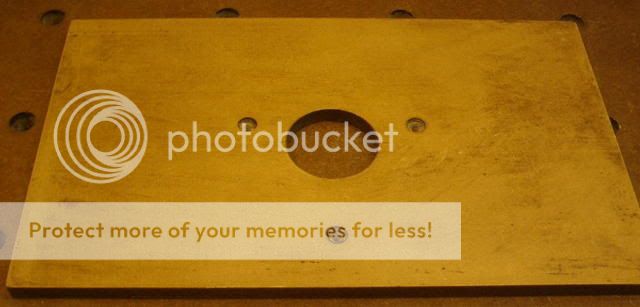

- Does the large base hole in the T11 make it less usable on smaller pieces?

- Are there any other contenders in this category?

- How often do router designs/updates occur? These machines seem to have been around a while, which is good, but are there likely to be newer versions around the corner?

V

Having read a lot of threads, I now fancy one of these two routers, but not sure if these large 1/2" jobbies will be usable for hand held use. I don't have a table (never used one), but plan to at some point.

I will use it mostly for speaker cabinet building.

- Suitable for hand held use?

- Does the large base hole in the T11 make it less usable on smaller pieces?

- Are there any other contenders in this category?

- How often do router designs/updates occur? These machines seem to have been around a while, which is good, but are there likely to be newer versions around the corner?

V