timwhatley

Member

I'm building a cabinet for my hall, and I've run into a dilemma that I could use some more experienced advice on.

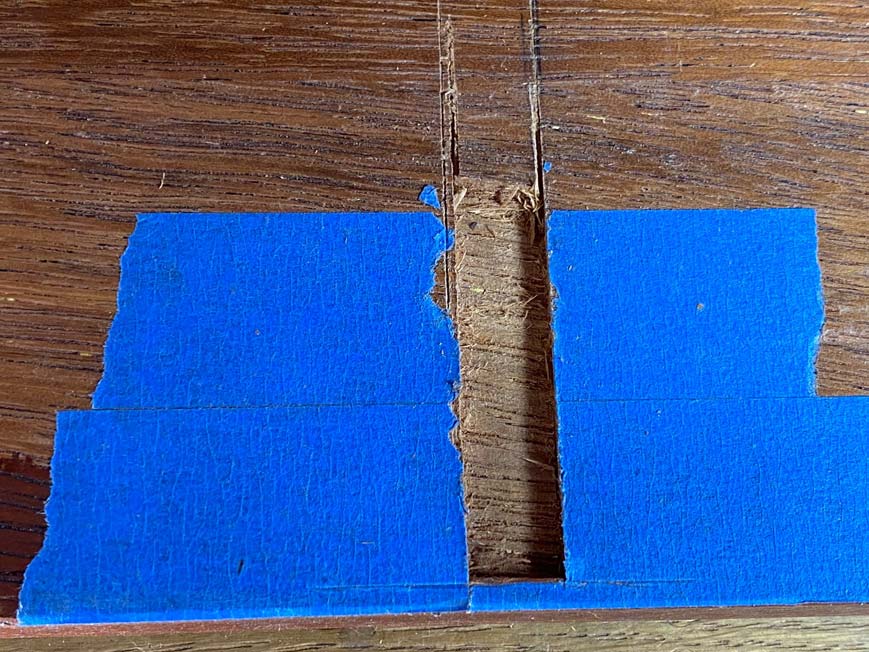

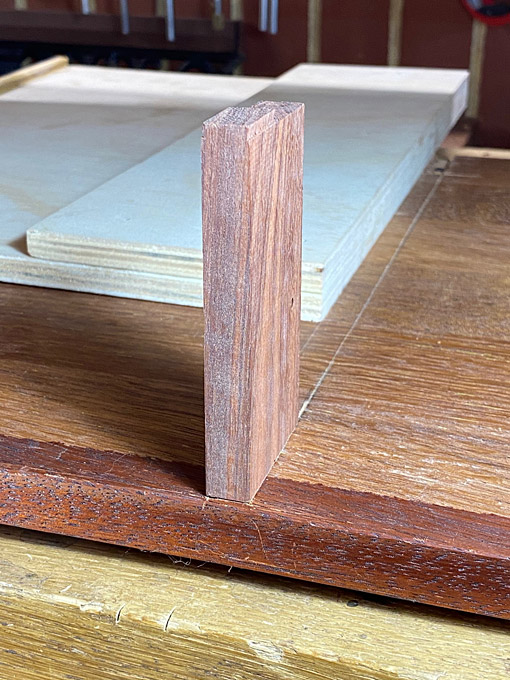

The case is solid cherry, with mitred dovetails on the corners and an inward facing bevel on the front edge. The bottom three full width spaces have solid panel divider, as they will become shelves for shoes (with a bottom hinged door on each). These are all held in stopped housing joints.

My question is about the vertical drawer dividers. When I sketched out the plans for this, I had thought I would cut a sliding dovetail to help support the weight of the drawers. However now I've come to that point in the build, I've realised I can't do that, as with the bevel on the front edge it would leave an ugly gap.

I could do a stopped housing, like I've done for the sides, but then there's no mechanical strength - just the hold of the glue. They are only relatively small drawers, and unlikely to hold much weight - but it still feels like a bad idea.. Am I overthinking things, or is there a joint that could add strength I'm not thinking of?

I have very few power tools, so hand tool options are preferred.

Thank you!

The case is solid cherry, with mitred dovetails on the corners and an inward facing bevel on the front edge. The bottom three full width spaces have solid panel divider, as they will become shelves for shoes (with a bottom hinged door on each). These are all held in stopped housing joints.

My question is about the vertical drawer dividers. When I sketched out the plans for this, I had thought I would cut a sliding dovetail to help support the weight of the drawers. However now I've come to that point in the build, I've realised I can't do that, as with the bevel on the front edge it would leave an ugly gap.

I could do a stopped housing, like I've done for the sides, but then there's no mechanical strength - just the hold of the glue. They are only relatively small drawers, and unlikely to hold much weight - but it still feels like a bad idea.. Am I overthinking things, or is there a joint that could add strength I'm not thinking of?

I have very few power tools, so hand tool options are preferred.

Thank you!