Thank you all for the response.

thinking about it with the helpof the comments, i do agree, it wont be taht strong.

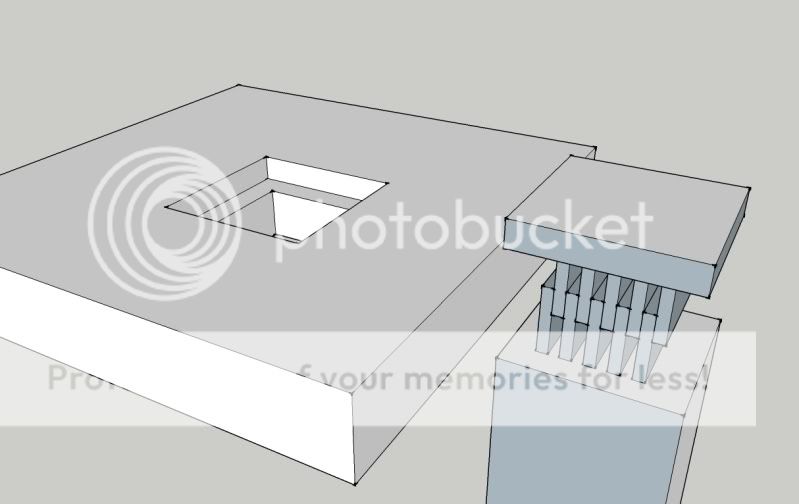

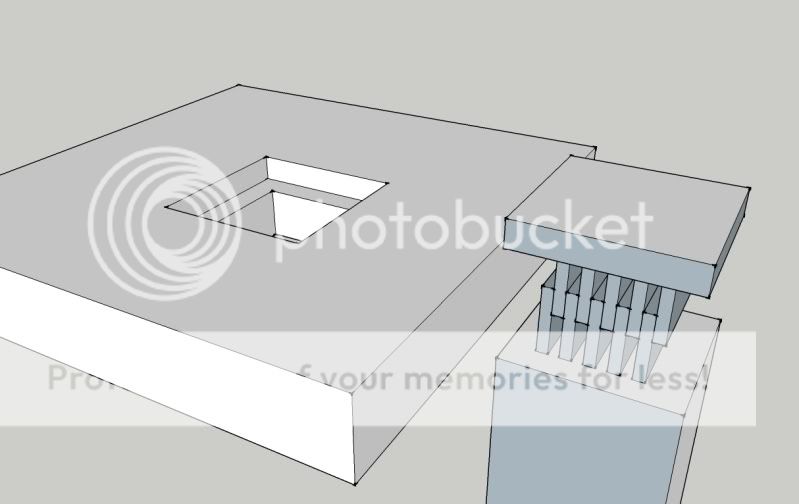

i was thinking of cutting the cap so that the finger would be perpendicular to the grain, which means they would be weaker.

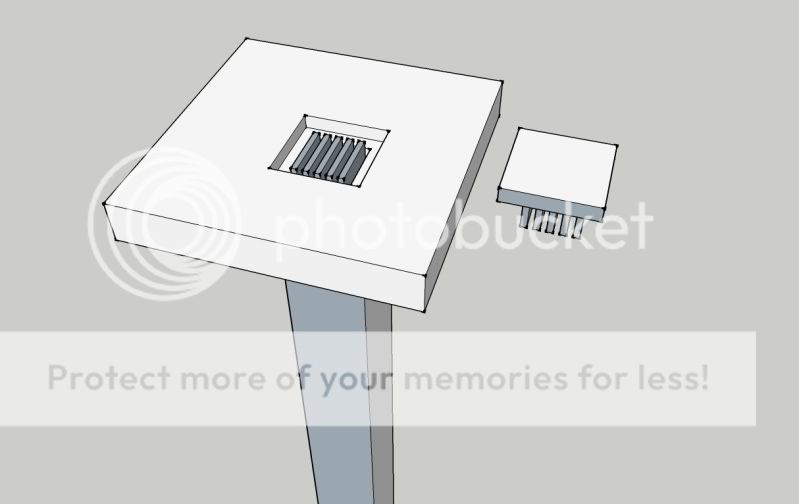

overall, the cap does not add to strength: i can see that by thinking this way: imagine i could route the fingers in the top from the underside (and the corresponding ones in the legs, and not make a separate cap.

The effect on the strength would be exactely the same as having the cap done in the way i drew it.

yet, it just means having 5or 6 thin tennons, rather than a think one.

would this be stronger ? i doubt. and infact, probably worse. if the thin tenons fail (breaking along the grain), that would be more catastrophic than the fat tennons coming unglued.

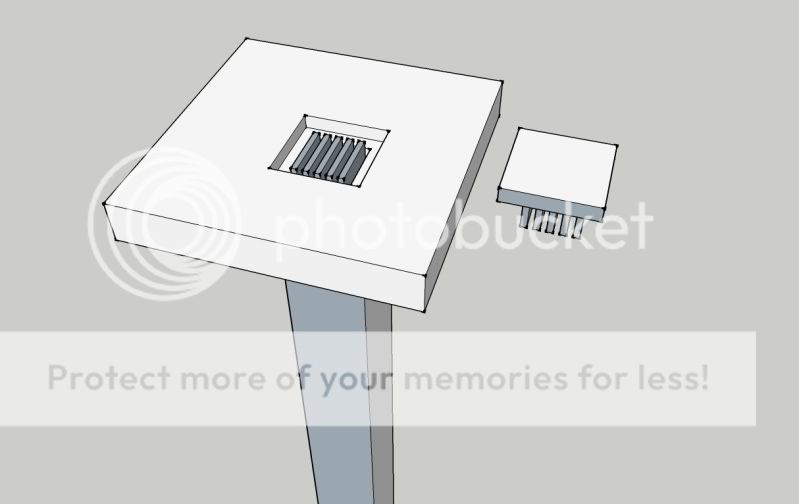

on the question of difficulty to make the join. i dont think it is that difficult.

a good table saw and some jigerry would make the fingers easy to cut.

the rest is not anymore difficult than a through tennon.

I am still left with the problem though. How to make the leg stronger.

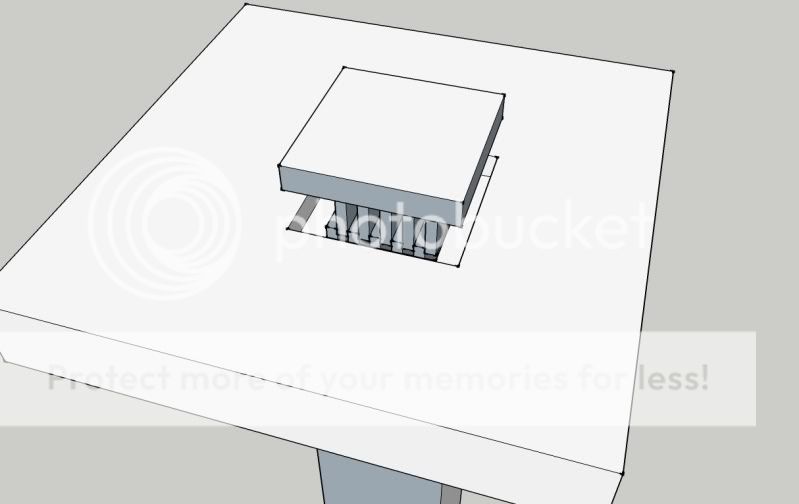

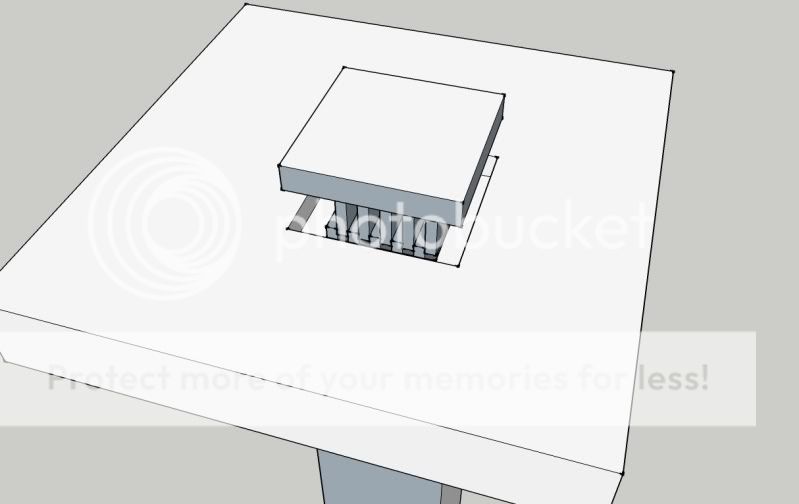

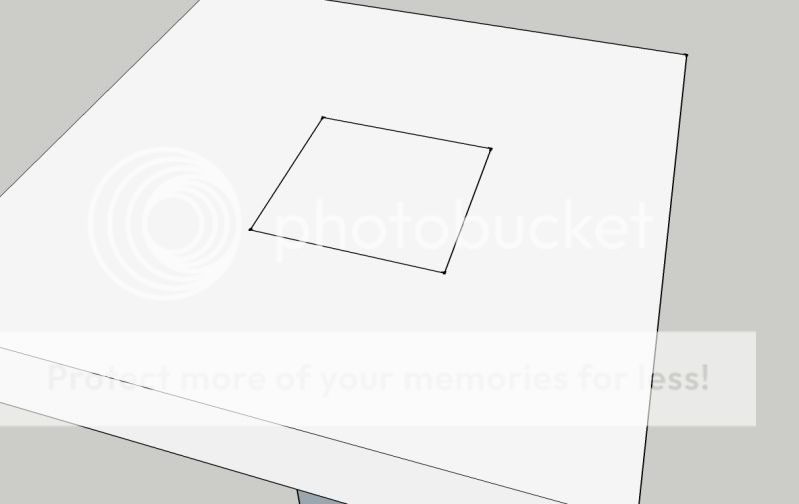

I cannot have a thicker top without compromising the design.

Similarly, the H braces underneath is also a compromise i cannot make just yet. The top needs to look feather light.

the back legs (or at least the inner leg braces) will rest on the rear drawer/compartment thing, but not the front ones.. the front drawer will be much smaller, and should just be big enough for a pen, or two.

The back compartement will be almost invisible when standing in front of the desk.

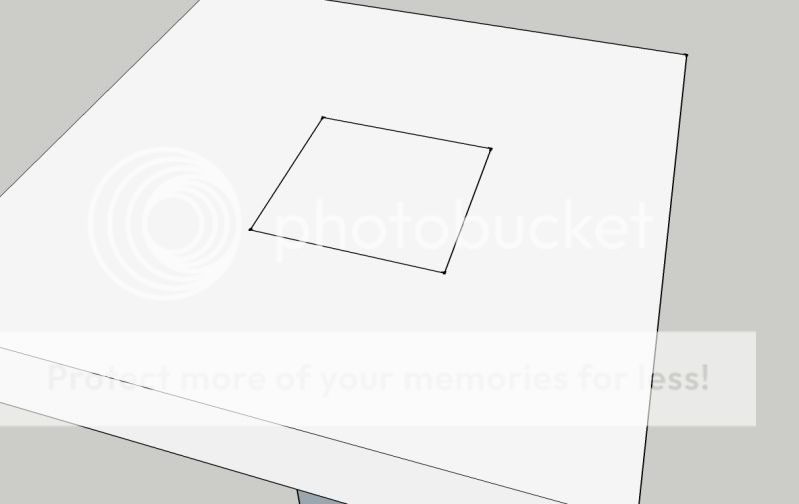

The more i am thinking about this, the more i think i will use "forbidden" techniques. I am thinking of a tennon, reenforced by a steel thread, through the leg and the top, with a washer and nut either side. of course, this will have to be built in the leg, with just the thread sticking out at the top. Then a block to cover the thread and nut in the top should hide the trickery.

Not for A levels or degree, btw.. just for the fun of it !

and of course, it is sketchup 7.0