davin

Established Member

Hello all.

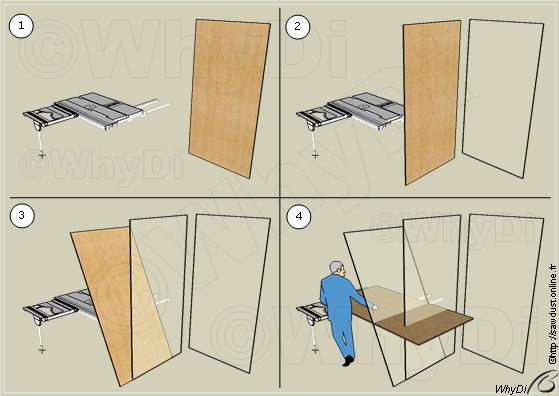

While I was staggering around the workshop today carrying an 8 by 4 sheet of ply, I began to think there must be a safer way of lifting a sheet onto a running panel saw than the method I was using.

How do others do it? I was thinking of a stand in front of the saw which I could safely lean boards against, before the big lift..

Any other ideas.

davin

While I was staggering around the workshop today carrying an 8 by 4 sheet of ply, I began to think there must be a safer way of lifting a sheet onto a running panel saw than the method I was using.

How do others do it? I was thinking of a stand in front of the saw which I could safely lean boards against, before the big lift..

Any other ideas.

davin