jonny2tanx

Member

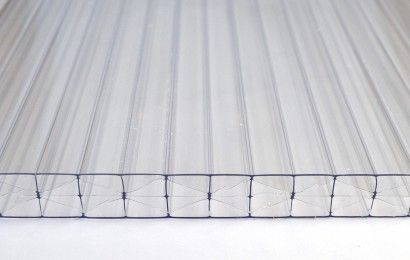

We have a pergola type of thing covering an area of decking outside our summerhouse. The pergola is covered in opaque corrugated plastic roofing sheet and the ends have reclaimed twin wall polycarbonate sheeting (thanks to our neighbour removing a conservatory) from 2" above the decking to the roof. The front is open apart from an area where I built a workshop which is closed at one end, semi open at the other end and at the front. We are experiencing high levels of condensation on the underside of the sheeting. Previously, before we reroofed the pergola and built the workshop, the roof was covered in clear corrugated sheeting (which had gone cloudy over the years) and the ends had bamboo screening instead of the polycarbonate. We never had a condensation problem with that set up.

So the changes we made are the type of sheet used - opaque rather than clear, and the closing off of the ends, although the front width is open to the elements. Is opaque sheet more susceptible to condensation or do you think it is the closing of the ends or a combination of both? Any advice will be gratefully received.

Many thanks

Jon

So the changes we made are the type of sheet used - opaque rather than clear, and the closing off of the ends, although the front width is open to the elements. Is opaque sheet more susceptible to condensation or do you think it is the closing of the ends or a combination of both? Any advice will be gratefully received.

Many thanks

Jon