Esteemed Galooterati,

having been a long-time lurker I now have a sufficiently knotty problem that you may be able to help with.

I am currently working on the top rail of a front door that will received leaded light top panels that have semi-circular and shouldered heads.

Accordingly I need to work a circular rebate (30mm wide, 10mm deep, radius 50 mm) into the rail to hold the glass. Unfortunately no electrons are available.

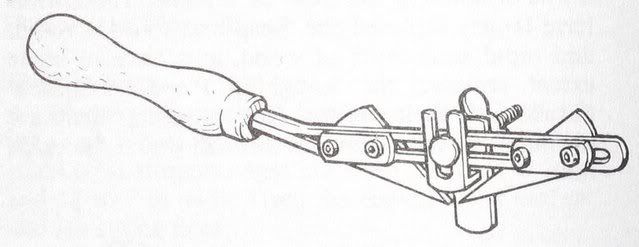

Cassel's Carpentry & Joinery recommend cutting a small groove along the curve with a quirk router and then removing the waste with a 'bent chisel'. Although I have the router (a Preston) the chisel is one I haven't come across, and I have not been able to find a modern equivalent. I have been using a circular hand router (Preston again), but the work is hard (especially across the grain), slow, and I have worn 2 nice blisters into my hands.

Are there any alternative hand methods for working such a rebate, or will I just have to put up with blisters until the I've finished ?

having been a long-time lurker I now have a sufficiently knotty problem that you may be able to help with.

I am currently working on the top rail of a front door that will received leaded light top panels that have semi-circular and shouldered heads.

Accordingly I need to work a circular rebate (30mm wide, 10mm deep, radius 50 mm) into the rail to hold the glass. Unfortunately no electrons are available.

Cassel's Carpentry & Joinery recommend cutting a small groove along the curve with a quirk router and then removing the waste with a 'bent chisel'. Although I have the router (a Preston) the chisel is one I haven't come across, and I have not been able to find a modern equivalent. I have been using a circular hand router (Preston again), but the work is hard (especially across the grain), slow, and I have worn 2 nice blisters into my hands.

Are there any alternative hand methods for working such a rebate, or will I just have to put up with blisters until the I've finished ?