Corneel

Established Member

Some philosofing and a bit of experience with vintage chisels, made me start a thread on chisel backs. I am especially interested in how these theories can be used in practice to reduce the amount of work to bring an old one back in shape and use it with pleasure.

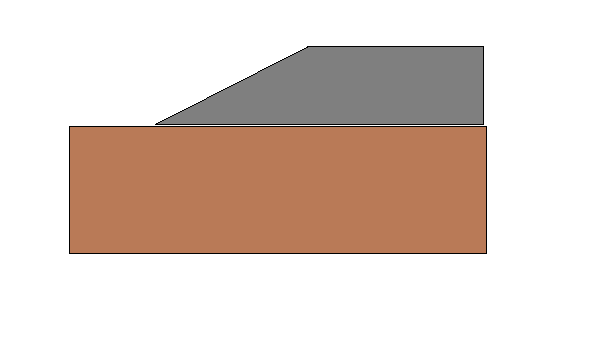

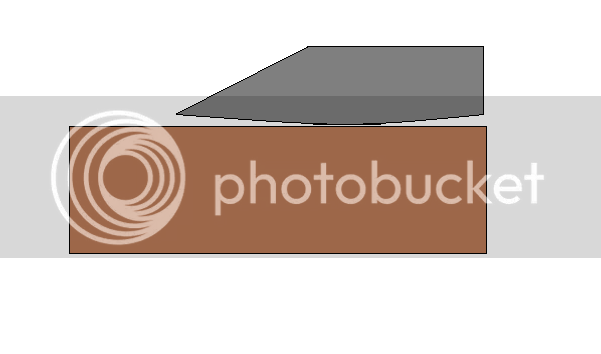

The ideal shape of a chisel has a flat back. Ideal, but hard to get in practice. But in use when paring wood this should work very nice. Light pressure on the tip and the chisel starts to cut. Also when registring the chisel from a reference surface this should be ideal, but I don't think that is a very common occurence in woodworking. A question with this shape is, how to keep it flat over time?

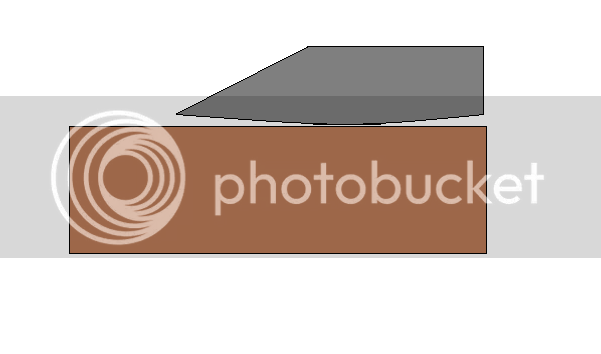

The concave back. This is often regarded to be ideal too. At least it is easy to sharpen. And over time it will tend to become flatter, which is more ideal probably. But in paring it might be a bit grabby? Tend to dive into the wood too easy?

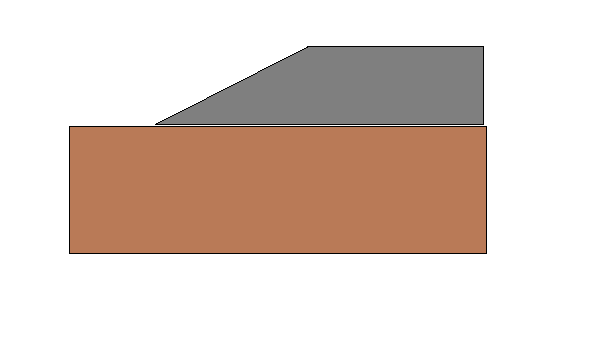

The convex back. Often regarded with dismay, but very common in the field. If the belly isn't too bad, how awfull can this be? It makes for a chisel which is easy to stear in the wood. Also sharpening this isn't difficult as long as you keep fingerpressure on the edge. Over time it will tend to become rounder, not flatter.

The true backbevel. This is probably something to avoid. The chisel doesn't want to cut when paring. Sharpening is also difficult.

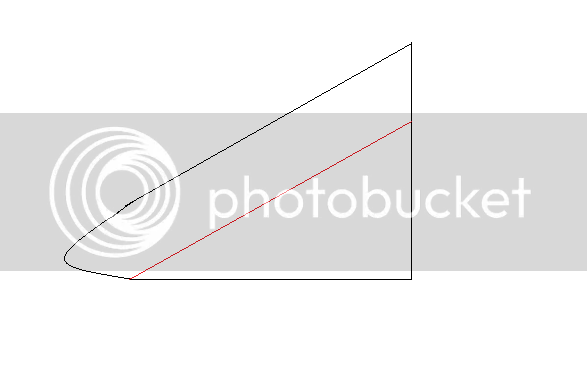

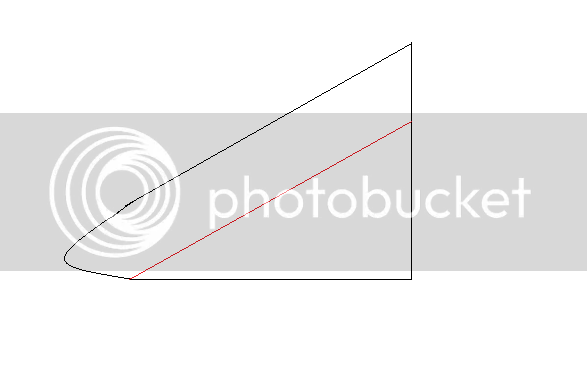

And then something about wear and sharpening. An edge wears round, thus creating a wearbevel both on the front and the back.

Usual practice is grinding back the bevel until you get a wire edge. That means grinding back to the red line which removes both wear bevels. Then just a light polishing wipe on the back to remove the wire edge. At the other hand, what if you want to avoid this scenario and give a quick hone often, what do you do exactly to avoid a backbevel?

Personally I'm not afraid for a heated argument but please try to remain civil to each other. My ideas in this are far from set in stone. I hope to learn something from the collective wisdom.

The ideal shape of a chisel has a flat back. Ideal, but hard to get in practice. But in use when paring wood this should work very nice. Light pressure on the tip and the chisel starts to cut. Also when registring the chisel from a reference surface this should be ideal, but I don't think that is a very common occurence in woodworking. A question with this shape is, how to keep it flat over time?

The concave back. This is often regarded to be ideal too. At least it is easy to sharpen. And over time it will tend to become flatter, which is more ideal probably. But in paring it might be a bit grabby? Tend to dive into the wood too easy?

The convex back. Often regarded with dismay, but very common in the field. If the belly isn't too bad, how awfull can this be? It makes for a chisel which is easy to stear in the wood. Also sharpening this isn't difficult as long as you keep fingerpressure on the edge. Over time it will tend to become rounder, not flatter.

The true backbevel. This is probably something to avoid. The chisel doesn't want to cut when paring. Sharpening is also difficult.

And then something about wear and sharpening. An edge wears round, thus creating a wearbevel both on the front and the back.

Usual practice is grinding back the bevel until you get a wire edge. That means grinding back to the red line which removes both wear bevels. Then just a light polishing wipe on the back to remove the wire edge. At the other hand, what if you want to avoid this scenario and give a quick hone often, what do you do exactly to avoid a backbevel?

Personally I'm not afraid for a heated argument but please try to remain civil to each other. My ideas in this are far from set in stone. I hope to learn something from the collective wisdom.