Evening all,

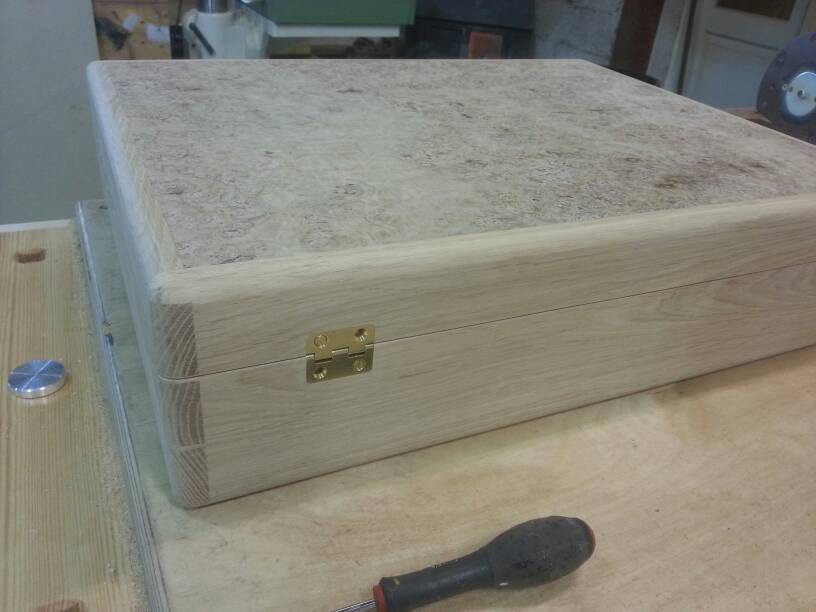

Over Christmas i decided id try making a laptop box with hand cut dovetails. It wasnt going to be anything special but i thought it would be a nice change from making windows every day.

The dovetails turned out o.k. I'd put aside a piece of oak mdf to use for the top and bottom but when it came to fitting, turned out the wood was too small anyway #-o :lol: It was then i had the silly idea to splash out a bit and buy some burr oak veneer.

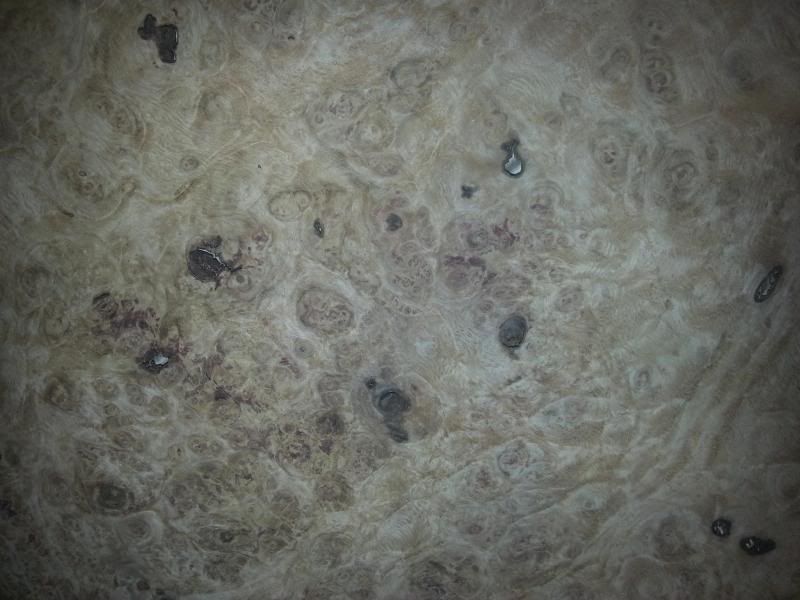

I thought it would be a simple case of sticking it onto a piece of ply then job done (hammer) The thing im stuck on is what i should do with all the holes. I had a look on the net and quickly became lost reading about gelatine flattening solutions and all kinds of other mumbo jumbo- so i havent done anything to it since :roll:

Im raring to go and get it stuck down and finished but could do with a little nudge in the right direction to get me started. Here's what ive kind of assumed so far-

its pretty flat so doesn't need any special kind of flattening

I could either stick it down as it is, then chisel out and patch it afterwards, or patch it before

perhaps some brummers or a mixture of sawdust and superglue

or a mixture of sawdust and superglue

give up, and just ruddy well buy one :shock:

Any pointers would be greatly appreciated. Ive got some titebond cold press glue ready and a vaccy bag, just need some hand holding (homer)

Coley

Over Christmas i decided id try making a laptop box with hand cut dovetails. It wasnt going to be anything special but i thought it would be a nice change from making windows every day.

The dovetails turned out o.k. I'd put aside a piece of oak mdf to use for the top and bottom but when it came to fitting, turned out the wood was too small anyway #-o :lol: It was then i had the silly idea to splash out a bit and buy some burr oak veneer.

I thought it would be a simple case of sticking it onto a piece of ply then job done (hammer) The thing im stuck on is what i should do with all the holes. I had a look on the net and quickly became lost reading about gelatine flattening solutions and all kinds of other mumbo jumbo- so i havent done anything to it since :roll:

Im raring to go and get it stuck down and finished but could do with a little nudge in the right direction to get me started. Here's what ive kind of assumed so far-

its pretty flat so doesn't need any special kind of flattening

I could either stick it down as it is, then chisel out and patch it afterwards, or patch it before

perhaps some brummers

give up, and just ruddy well buy one :shock:

Any pointers would be greatly appreciated. Ive got some titebond cold press glue ready and a vaccy bag, just need some hand holding (homer)

Coley