johnelliott

Established Member

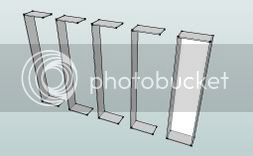

I've been asked to quote for creating a wall of cupboards on a wall that is about 2.5metres tall and about 2.8metres long. Seems to me to divide reasonably into 3 rows of cupboards high average about 750mm high and 5 cupboards wide around 560mm wide. Cupboards can only be about 300mm deep.

My normal way of doing built-ins is to make a box a bit smaller than the space, then fit it with scribing strips on three sides and a plinth at the base. This gives me a square box (always easier to fit a door to a square box) a back, and sides that can be drilled for shelves and also take kitchen style hinges.

Doing this job this way would mean a price based on 15 such boxes, and will work out a good deal more than I think this customer is looking to spend.

I don't actually need this job at all, but it is, never-the-less, an interesting problem.

Perhaps a less expensive way would be to shelve the wall and then create a framework in front of it that could take the doors?

What does the panel suggest?

John

My normal way of doing built-ins is to make a box a bit smaller than the space, then fit it with scribing strips on three sides and a plinth at the base. This gives me a square box (always easier to fit a door to a square box) a back, and sides that can be drilled for shelves and also take kitchen style hinges.

Doing this job this way would mean a price based on 15 such boxes, and will work out a good deal more than I think this customer is looking to spend.

I don't actually need this job at all, but it is, never-the-less, an interesting problem.

Perhaps a less expensive way would be to shelve the wall and then create a framework in front of it that could take the doors?

What does the panel suggest?

John