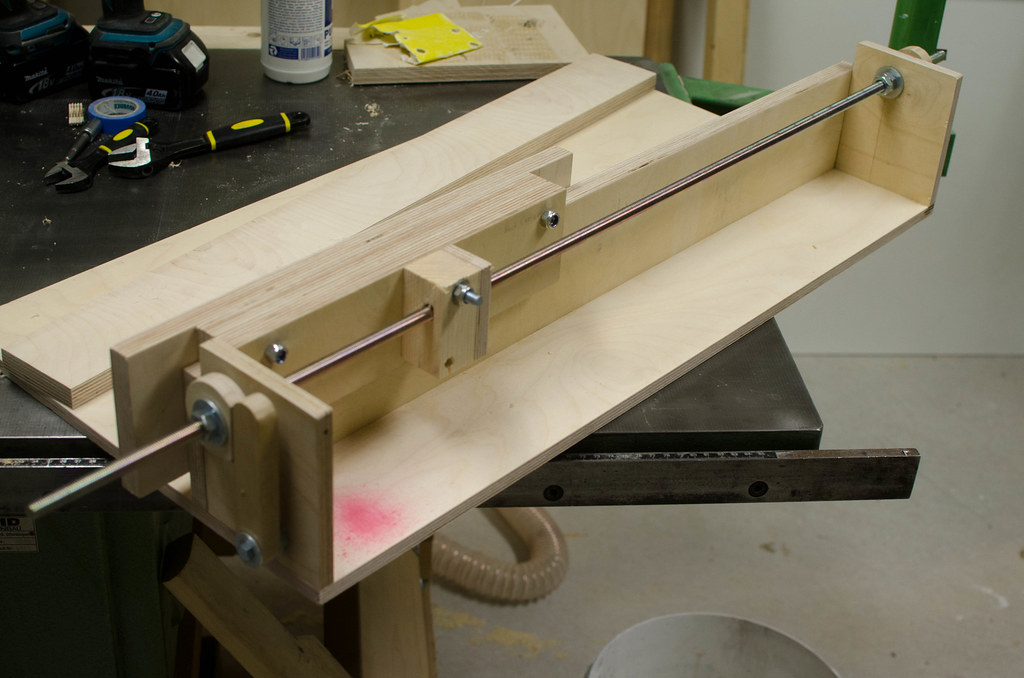

Put it together finally and did some test cuts but I got gappy joints, so it would seem that despite the 1.5mm pitch and 3mm blade things are out of spec enough. This can be avoided I think by removing the cam and using quarter and half turns, but that makes it kinda complicated. I believe I now see the advantage in Matthias Wandels gear driven jig, thanks to customizable gear ratios you can overcome the issue of thread pitch having to equal very precisely an even fraction of the blade kerf.

I'll continue working on this jig and see if another blade would work, I think this has some wobble to it and that might be the culprit.