This matter has been discussed on FWW Knots many many times and that's not just my conclusion, but the general concensus over there, too. Scrit

I suspect you may in part be referring to me, Scrit, as I've been involved in some of those debates. I might, in fact, have been one of the first on that forum to alert other forum users to the rugby ball shaped depressions that can show when biscuits are used in edge joints. I'm guessing now, but I think I may have first mentioned this phenomenom on that forum back in about 1999. I think I first noticed the depression forming tendencies of biscuits in the mid or late '80's.

All that you say is true. The wood is pooched up if water based glue is introduced to both the edge faces of the joint and the groove part of the biscuit joint. The biscuits at some point during their manufacture I understand are steamed and hydraulically compressed. It's one way of ensuring they swell sufficiently to make a tight joint with their wee groove when moisture is added to the mix. In other words they're not designed for use with epoxy resins and polyurethane glues (for example) because they don't have water in them to swell the biscuits.

In any event, I always recommend to those that are inexperienced with slab glue ups done with water based glues, whether using biscuits or not, to wait for about a week after removing the clamps so that all the moisture introduced into the area can leave it. This allows the swollen timber to shrink properly again to match the rest of the panel glue up's moisture content.

Doing this means that the oval depressions are unlikely to appear later, and nor do the characteristic glue line furrows that can also show up. Allowing sufficient time between glue up and polish prepping I find means that the biscuits can be placed centrally in the thickness. My experience that the sometimes suggested advice to put the biscuits towards the bottom face of the joint is a bit of a canard. The wood still swells when moisture is added. Planning the job allowing sufficient time for the moisture to leave the wood seems to work best.

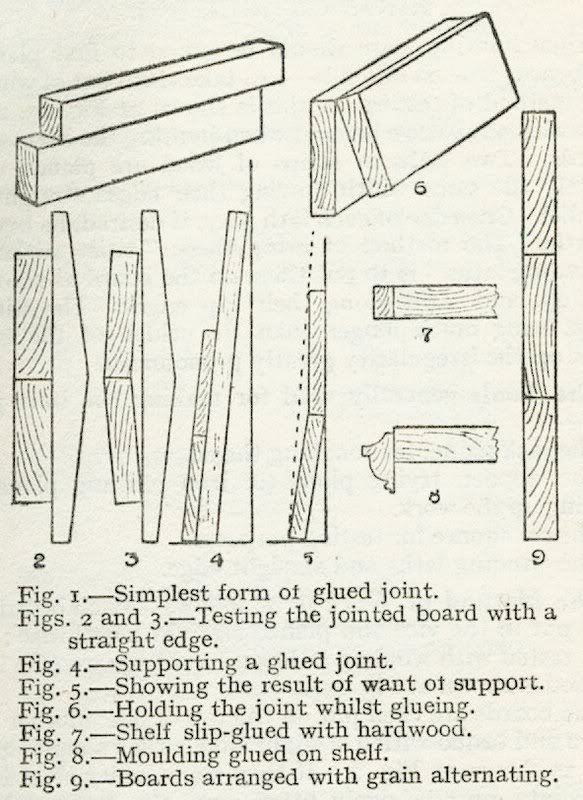

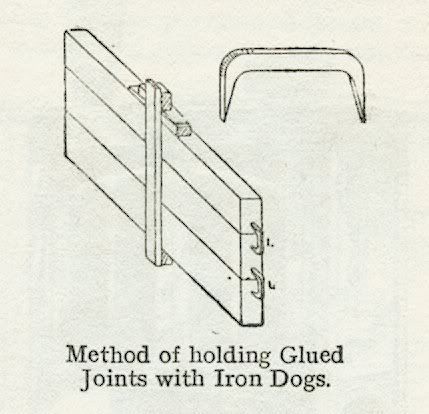

I see nothing fundamentally wrong with using biscuits in edge joinery. They're like splines, tongues and grooves, dowels, etc., that have been around and used for centuries with success. Where I do find them a bit of an irritant is during the actual glue-up. They're fiddly and slow down the process meaning it takes longer to get the clamps on, which can be bad news if the glue has skinned off before you can get pressure on.

Regarding the original question about spacing-- about 250 mm to 370 mm usually works pretty well. Just make sure you don't cut through one when you trim the top to length, ha, ha. Slainte.

. My question is - how close together should the biscuits ideally be? The boards are about 2m long. I've had a look through previous posts but still can't find an answer to this.

. My question is - how close together should the biscuits ideally be? The boards are about 2m long. I've had a look through previous posts but still can't find an answer to this.