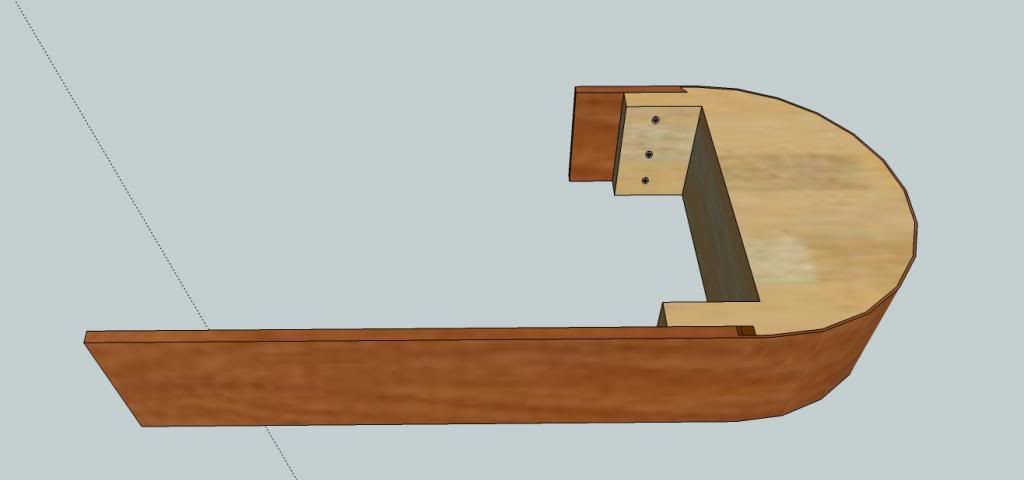

If you have a moulding underneath the nose, plane a piece down to the right thickness then put a radius on, mould etc and glue it. Groove it with a router to accept the riser (I usually do 'em 15mm) .

Kerf the riser about an inch before and after the spring line, I usually take it down to 2mm depending on how tight the curve is. If you have a table saw with a sliding carriage you can make a jig by fixing a backing piece against the fence with a nail or screw that is the same width as the saw blade kerf. Everytime you cut a kerf, slip it over the nail which will give you equal distances and a nice smooth curve. Quarter sawn stuff works best.

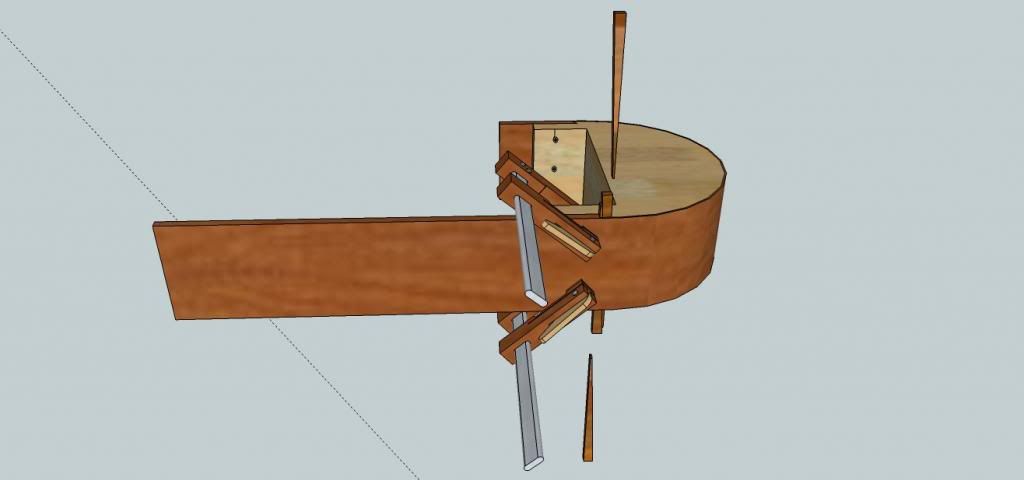

Be careful with the curved blocks in regards to newel posts as its a bit of a mare having to chop bits out if they are in the way.