sm7

Established Member

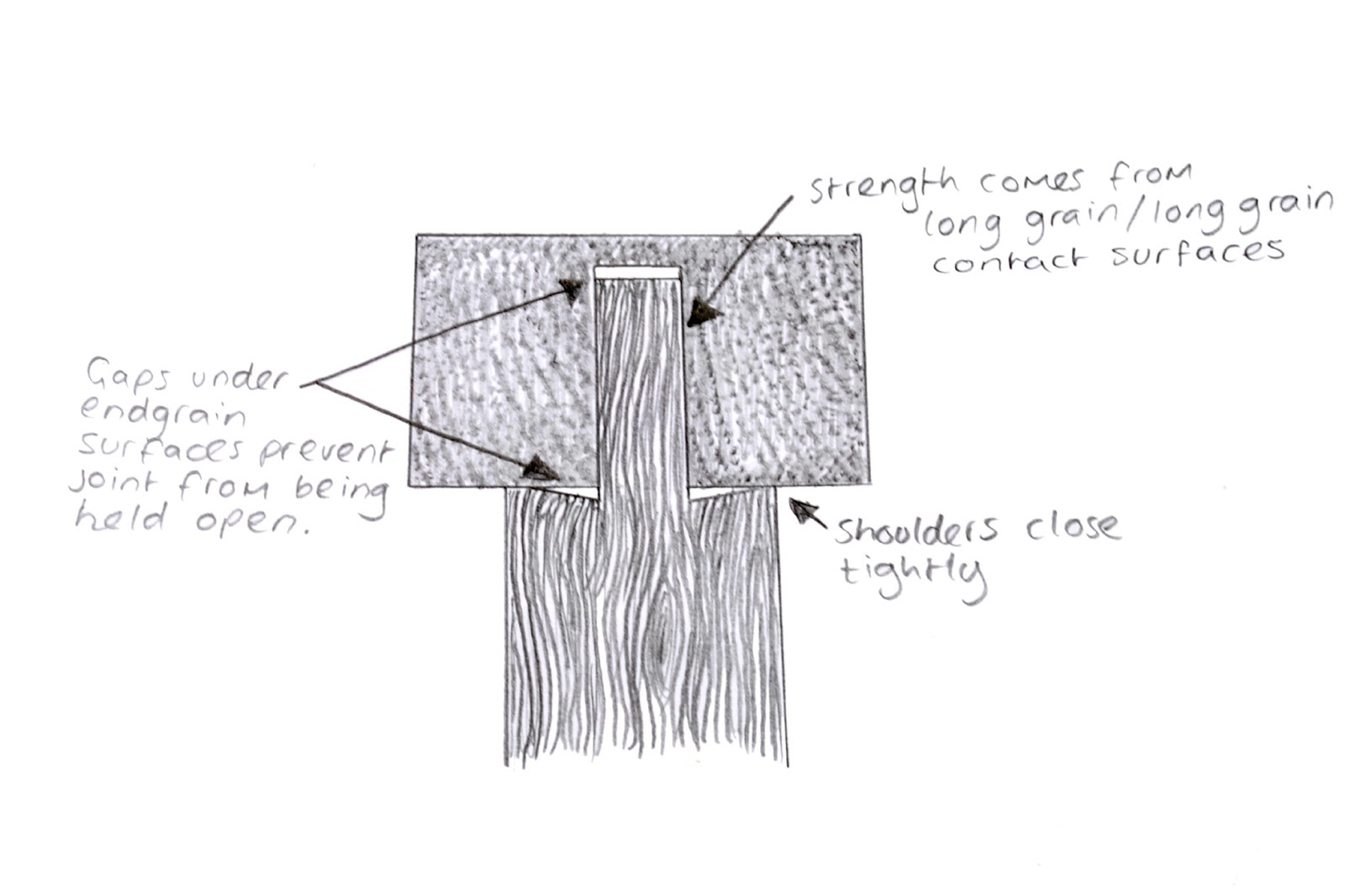

So I've spent the last couple of days practicing my finger and dovetail joints. They fit snugly, not quite to the point where they require tapping in with a mallet, but well enough to hold in place. Although there is a long way to go before my work becomes even close to being worthy of building anything, I am improving; my cuts have become more true, my measuring has become more accurate and my understanding of the way the wood will react to what I do has increased. However, despite this, my dovetail and finger joints are still horribly messy and do not sit flush, the distal ends of my fingers/dovetails extend beyond the pins and sometimes the edges of the board do not meet properly.

I understand that this is all practice and am not discouraged by this, but I was just wondering how to go about "tidying up" joints when they look like this. There are many instructional videos that I have watched on how to cut the dovetails, but all the ones I have seen end at tapping the joint home and it looking fantastic. None go into the process of planing the joint down or paring out the sockets to make sure the dovetail sits flush to the socket base, or any of the other techniques for ensuring that the joint is perfect. I was wondering if anyone could explain this process to me as my joints aren't perfect straight from the cut and I don't know what to do to make them fit properly.

Thanks,

Sam.

I understand that this is all practice and am not discouraged by this, but I was just wondering how to go about "tidying up" joints when they look like this. There are many instructional videos that I have watched on how to cut the dovetails, but all the ones I have seen end at tapping the joint home and it looking fantastic. None go into the process of planing the joint down or paring out the sockets to make sure the dovetail sits flush to the socket base, or any of the other techniques for ensuring that the joint is perfect. I was wondering if anyone could explain this process to me as my joints aren't perfect straight from the cut and I don't know what to do to make them fit properly.

Thanks,

Sam.