Richard T

Established Member

Inspired by Sheffield Tony's recent thread badger-plane-t63760.html and The Woodwright's Shop episode about panel raising http://video.pbs.org/video/2292074921 I was reminded that I was given a Badger plane a couple of years ago and thought it was about time I had a go at it.

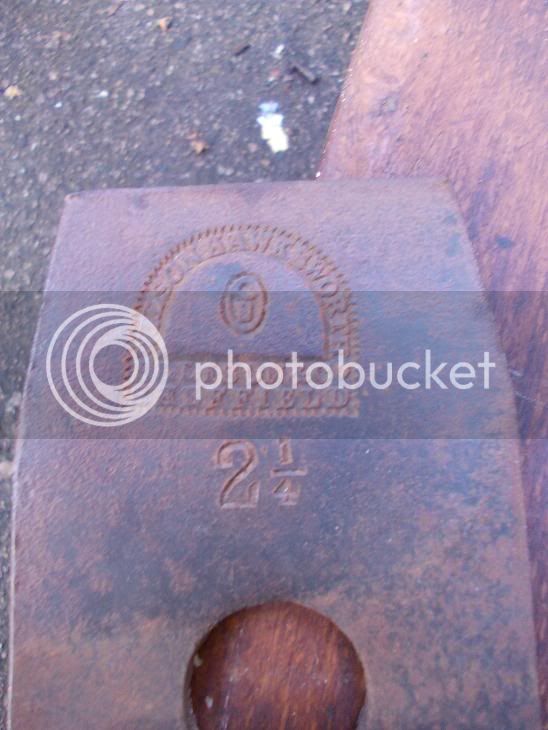

Struck me as being not too bad when I got it.

But on closer inspection I found that the iron was more pitted than I had thought and even showed signs of a deep back bevel.

Only one way to find out - to the XXcoarse diamond stone.

Yup. Not only did it have a back bevel but the useful back bevel was only towards the more used right hand side of the iron, and towards the left hand side, less a bevel more an incline.

So the diamond stone was retired in favour of XXXXXXX coarse emery on a piece of steel plate on top of the plane body on its side.

Much better.

I am very glad that I found the wedge. At first I thought it had disappeared and that I would have to make a new one ... so glad that I don't - these angles are a nightmare. Just to get that skew there is so much else to get right.

Roy Underhill's badger has a repair that is a small, brass plate surrounding the edge of the iron on the face cutting side. I can see why. This one is starting to go there too.

But to make such a repair plate, the internal shape would have to be followed, which would mean a fair bit of metal work to match the wood going down to a feather edge at the bottom.

Here is the thickness of the side of the body at the top

... tapering down to nothing at the bottom.

Once I get it sharp I will try it first before any brass work.

The cap iron is suspect too. It has this horrible nut and bolt through the brassed thread which has been drilled out to fit it. :evil: My options for this are: leave as is - it works, skew another straight lever cap to match, re thread the remaining brass and cut a bigger bolt or watch Bargain Hunt .... I'll decide after Bargain Hunt.

Roy has two dodgy theories about the name Badger; A company called Badger made them or a badger has a sort of sideways gait ... I don't think it's either of those. I think it's more literal than that. Please don't try to tell me that this tote was made for a human ...

... it's much too small. Definitely for a badger. How else do they cut those setts out?

Anyway, I haven't shown it an oil stone yet so test cut pictures later.

Struck me as being not too bad when I got it.

But on closer inspection I found that the iron was more pitted than I had thought and even showed signs of a deep back bevel.

Only one way to find out - to the XXcoarse diamond stone.

Yup. Not only did it have a back bevel but the useful back bevel was only towards the more used right hand side of the iron, and towards the left hand side, less a bevel more an incline.

So the diamond stone was retired in favour of XXXXXXX coarse emery on a piece of steel plate on top of the plane body on its side.

Much better.

I am very glad that I found the wedge. At first I thought it had disappeared and that I would have to make a new one ... so glad that I don't - these angles are a nightmare. Just to get that skew there is so much else to get right.

Roy Underhill's badger has a repair that is a small, brass plate surrounding the edge of the iron on the face cutting side. I can see why. This one is starting to go there too.

But to make such a repair plate, the internal shape would have to be followed, which would mean a fair bit of metal work to match the wood going down to a feather edge at the bottom.

Here is the thickness of the side of the body at the top

... tapering down to nothing at the bottom.

Once I get it sharp I will try it first before any brass work.

The cap iron is suspect too. It has this horrible nut and bolt through the brassed thread which has been drilled out to fit it. :evil: My options for this are: leave as is - it works, skew another straight lever cap to match, re thread the remaining brass and cut a bigger bolt or watch Bargain Hunt .... I'll decide after Bargain Hunt.

Roy has two dodgy theories about the name Badger; A company called Badger made them or a badger has a sort of sideways gait ... I don't think it's either of those. I think it's more literal than that. Please don't try to tell me that this tote was made for a human ...

... it's much too small. Definitely for a badger. How else do they cut those setts out?

Anyway, I haven't shown it an oil stone yet so test cut pictures later.