mikefab

Established Member

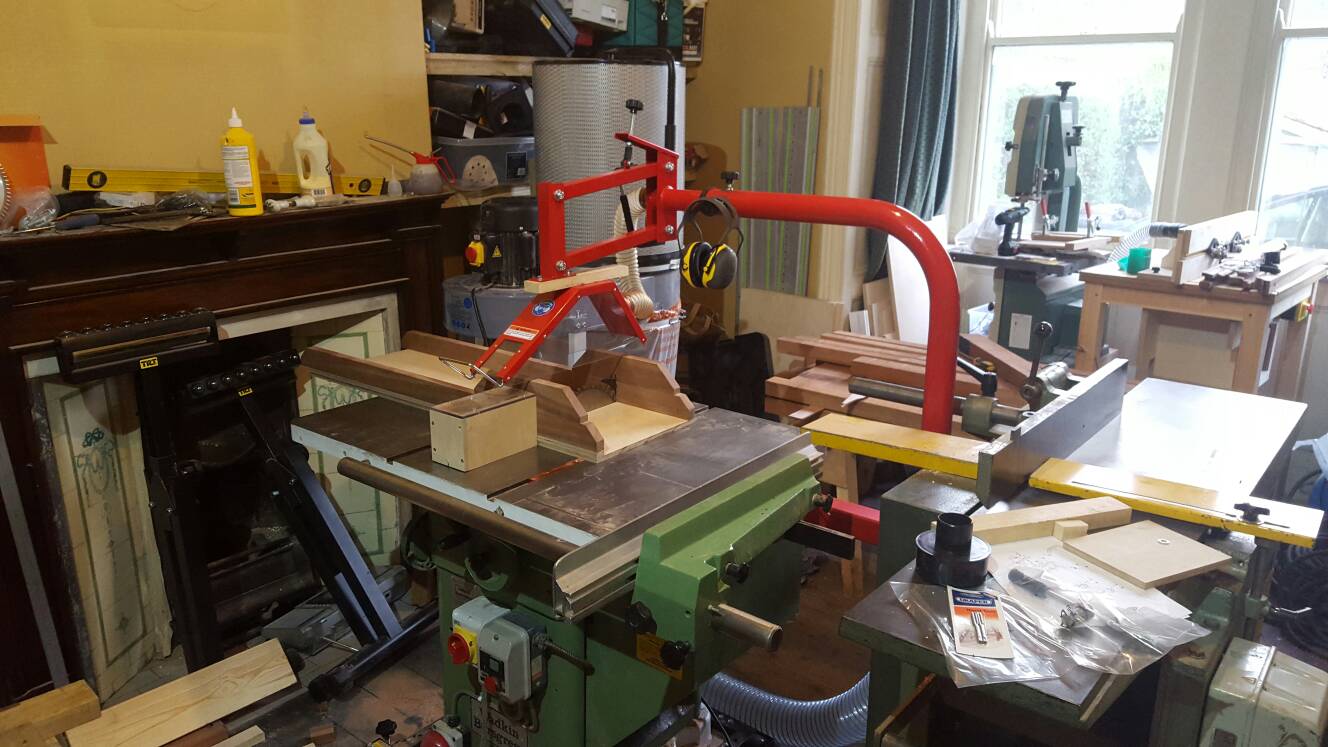

I recently bought this to go on my Wadkin AGS 10. The local Axminster branch were very helpful in getting the trade version out for me to look at and phoning another branch to get measurements of the industrial version. It is designed to fit their 12" saw bench but will accommodate a right hand extension table so it is big and I had to modify it. I'm a bit tight for space at the moment as I have a temporary workshop in our house while I finish the renovations and get a workshop built!

This is far more heavy weight that the pictures online suggest. It weighs over 30kg and the tubing is 60mm diameter. As supplied the arm length is 1200mm so it would have protruded miles to the right of the saw and fouled my PT. So I cut it down and redrilled holes for the hand screws which clamp the guard in place before heading out to the local car fixers to get some M8 nuts welded over the holes (this is how the guard worked originally). I needed to drill 4x 10mm holes in the saw body at the back for the mounting bracket. I measured up VERY carefully! Still needed to ease one hole with a file though...

The guard was also fouling the blade as it is quite close to the back of my saw table so you can see I have inserted a bit of wood to offset it to the correct position. I will replace this with a piece of steel when I have a moment.

In use I am pleased with it so far. The guard is wide enough to accommodate a blade at 45 degrees although it may need to be slid one way or the other using the hand screws and extending mechanism on the top arm. The guard moves up and down nicely, assisted by a gas strut. It can be held at the chosen height by adjusting the lock screw at the top. To change the blade I lock it up high and then shorten the top tube to move the whole assembly out of the way. I have found it is necessary to preset the height rather than allow the workpiece to push the guard up.

Dust extraction is from the bottom and takes a 65mm hose which I have stepped up to 100 here.

The guard can be seen for sale here http://www.axminster.co.uk/axminster-industrial-series-tsce-12r-overhead-crown-guard-kit-508229

Hope this is of interest!

Mike

This is far more heavy weight that the pictures online suggest. It weighs over 30kg and the tubing is 60mm diameter. As supplied the arm length is 1200mm so it would have protruded miles to the right of the saw and fouled my PT. So I cut it down and redrilled holes for the hand screws which clamp the guard in place before heading out to the local car fixers to get some M8 nuts welded over the holes (this is how the guard worked originally). I needed to drill 4x 10mm holes in the saw body at the back for the mounting bracket. I measured up VERY carefully! Still needed to ease one hole with a file though...

The guard was also fouling the blade as it is quite close to the back of my saw table so you can see I have inserted a bit of wood to offset it to the correct position. I will replace this with a piece of steel when I have a moment.

In use I am pleased with it so far. The guard is wide enough to accommodate a blade at 45 degrees although it may need to be slid one way or the other using the hand screws and extending mechanism on the top arm. The guard moves up and down nicely, assisted by a gas strut. It can be held at the chosen height by adjusting the lock screw at the top. To change the blade I lock it up high and then shorten the top tube to move the whole assembly out of the way. I have found it is necessary to preset the height rather than allow the workpiece to push the guard up.

Dust extraction is from the bottom and takes a 65mm hose which I have stepped up to 100 here.

The guard can be seen for sale here http://www.axminster.co.uk/axminster-industrial-series-tsce-12r-overhead-crown-guard-kit-508229

Hope this is of interest!

Mike