Pecker

Established Member

Hi all, I may have a project coming up that requires 600 or so smiley faces to be cut into 9mm mdf. The thought of getting a small cnc type machine crossed my mind, but was horrified to see the costs! (£5000 is a bit more then the job is worth LOL)

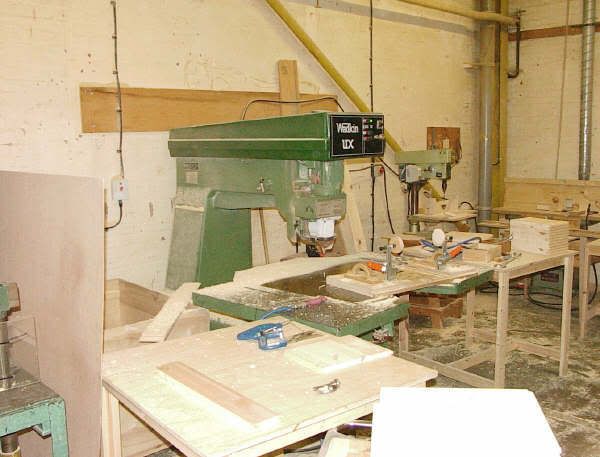

Has anyone any suggestions of an alternative or have any experience of building one? (apparently basic milling machines can be converted, but it has to be practical... )

otherwise it's a new small router and jig...

For various reasons I do not wish to farm the work out.

Woody

Has anyone any suggestions of an alternative or have any experience of building one? (apparently basic milling machines can be converted, but it has to be practical... )

otherwise it's a new small router and jig...

For various reasons I do not wish to farm the work out.

Woody