In an attempt to get something done in the 'shop i wanted to make a small cabinet which could hold my layout tools.

As i got a starting set of Miller dowels for Christmas i wanted to incorporate that and i also had some walnut pocket hole plugs which i wanted to try.

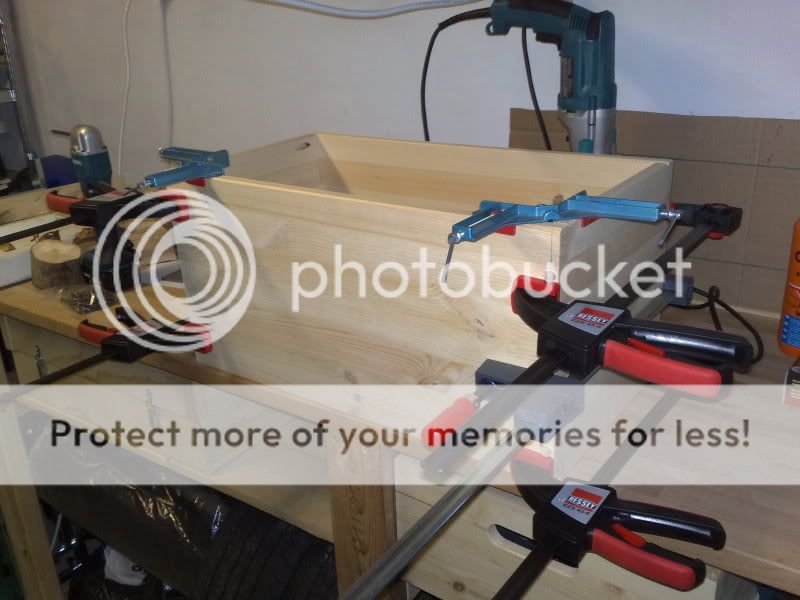

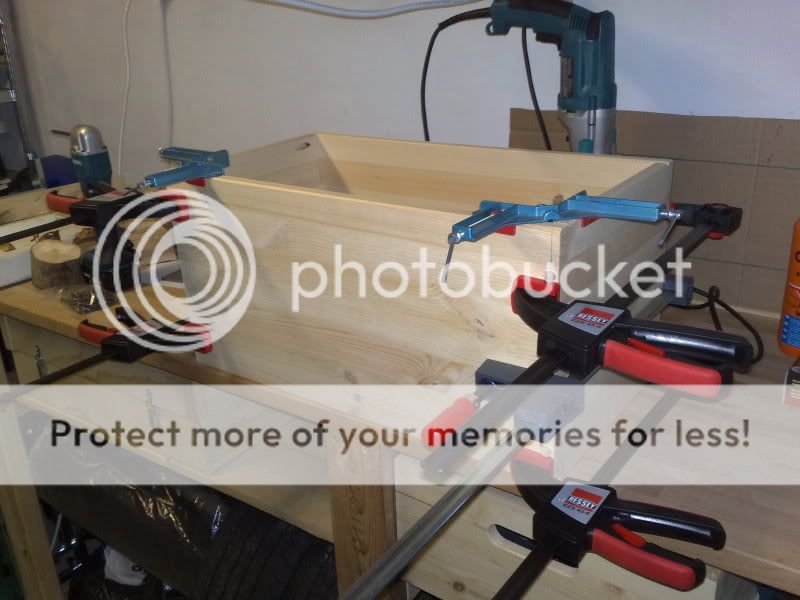

So i set out to make a carcass, unfortunately, and being the newbie here i forgot to take any pic's before this one of the gluing up of the carcass:

I fully agree one can never have enough (Bessey) clamps.

Here's the Miller Dowels, i have learnt that it's of importance to let the drillbit up several times to get rid of the debris. If not it just makes a way out itself. Visible in the pic. That didn't happen on the other side, and since this is a tool cabinet i just note what i learnt and carry on.

Visible in the pic. That didn't happen on the other side, and since this is a tool cabinet i just note what i learnt and carry on.

Inside for the bottom i used pocket hole screws and walnut plugs against the pine carcass looks OK'ish:

Which in turn sees me here:

Then a door is needed. I have decided to use Lexan equivalent inside a basic frame:

Then clamps again. I built this from scrap after looking at various solutions and full of inspiration from reading on here:

And door in clamps:

Small euro- hinges and it's a cabinet of sorts:

Learnt a lot and any critique and/or helpful hints and tips are welcome.

Thanks for looking!

As i got a starting set of Miller dowels for Christmas i wanted to incorporate that and i also had some walnut pocket hole plugs which i wanted to try.

So i set out to make a carcass, unfortunately, and being the newbie here i forgot to take any pic's before this one of the gluing up of the carcass:

I fully agree one can never have enough (Bessey) clamps.

Here's the Miller Dowels, i have learnt that it's of importance to let the drillbit up several times to get rid of the debris. If not it just makes a way out itself.

Inside for the bottom i used pocket hole screws and walnut plugs against the pine carcass looks OK'ish:

Which in turn sees me here:

Then a door is needed. I have decided to use Lexan equivalent inside a basic frame:

Then clamps again. I built this from scrap after looking at various solutions and full of inspiration from reading on here:

And door in clamps:

Small euro- hinges and it's a cabinet of sorts:

Learnt a lot and any critique and/or helpful hints and tips are welcome.

Thanks for looking!