SkinnyB

Established Member

So I recently took a punt on a Bostich GF33PT-U sold as faulty on eBay. I have one already so would be great for spares if I couldn't get it working.

Seller didn't exactly make it clear what was wrong but spare parts were available to buy.

On receipt of the nail gun turned out the piston which hits the nail had broken in two. Gutted! £130 for a new part. One of the worst parts to go!

Screenshot 2018-11-25 at 12.15.43 by jamie skinner, on Flickr

Screenshot 2018-11-25 at 12.15.43 by jamie skinner, on Flickr

Unknown by jamie skinner, on Flickr

Unknown by jamie skinner, on Flickr

So I looked into a few ways of repairing it.

A few options:

Remove the hardened steel flat bar from the base and replace it with something else. Not sure if id actually be able to do it.

Buy a new one

Id recently remembered a 'This Old Tony' video on youtube about silver brazing. After some research seemed the way to go.

So this is how I did it:

(Please note I'm no metal worker, just going off that I thought would be a good idea.)

Its a nice clean break so I think im all good. I decided to add two grooves on either side to increase the surface area of the braze and to have some thicker parts of silver solder to brace the join. I used a magnet to hold the parts together while I used a Dremel cut off wheel on it. Also gave the parts a good clean with a wire wheel. Clean joints work best.

IMG_3035 by jamie skinner, on Flickr

IMG_3035 by jamie skinner, on Flickr

IMG_3036 by jamie skinner, on Flickr

IMG_3036 by jamie skinner, on Flickr

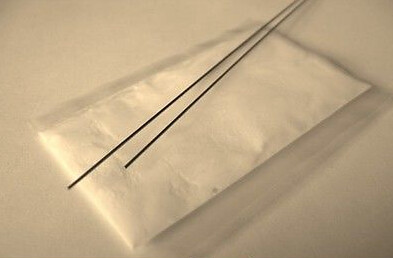

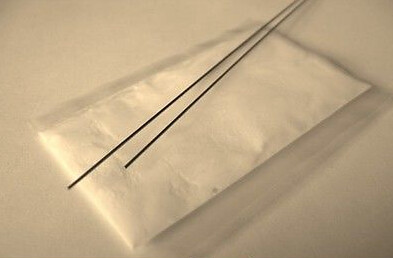

I brought a silver solder kit for £7 which was 55% silver with flux. I have access to a hearth but if not you could use a torch of some kind. Easily manageable in a home shop.

IMG_3037 by jamie skinner, on Flickr

IMG_3037 by jamie skinner, on Flickr

Screenshot 2018-11-25 at 12.25.57 by jamie skinner, on Flickr

Screenshot 2018-11-25 at 12.25.57 by jamie skinner, on Flickr

Mixed the flux powder with water and applied to join. I applied both sides at once. From what I researched the silver will flow to wherever the heat and flux are. Heated to a red hot then applied silver to the joint. it flowed all the way around. Looked great. Then I think I did the next part right: I quenched it in water. As its hardend this should have kept it harder to a certain degree.. Think there is more science to it though!

IMG_3038 by jamie skinner, on Flickr

IMG_3038 by jamie skinner, on Flickr

Brazed joint:

IMG_3039 by jamie skinner, on Flickr

IMG_3039 by jamie skinner, on Flickr

Not the prettiest joint but seemed to work. I didn't really have anything to hold down the small piece so it moved ever so slightly when I brazed. Learnt something for next time!

IMG_3041 by jamie skinner, on Flickr

IMG_3041 by jamie skinner, on Flickr

IMG_3042 by jamie skinner, on Flickr

IMG_3042 by jamie skinner, on Flickr

Looking at where this goes in the nail gun the slightly thicker joint silver braze part clears everything so I left it as is to maintain as much strength as possible. I applied some friction reducer liquid I have to the channel it sits in.

One thing that concerned me was getting it brazed straight, as when this strikes the nail it sticks at some force! Any slight bend and it would problem crack.

So looks pretty good! Im surprised at how strong this is! (Famous last words maybe...)

IMG_3040 by jamie skinner, on Flickr

IMG_3040 by jamie skinner, on Flickr

So did it work? Well surprisingly yes!! Drove a 90mm nail into my floor. I have a deck to build next year so will put it through it paces then.

IMG_3082 by jamie skinner, on Flickr

IMG_3082 by jamie skinner, on Flickr

I also painted it a metallic colour to differential between my other one. Gave it a good clean and service. Not bad for a total cost of repair and gun for £55.

Just found out the batteries don't hold a charge so next step is to replace those.

Thanks for reading. May be of some help for someone else.

IMG_3085 by jamie skinner, on Flickr

IMG_3085 by jamie skinner, on Flickr

IMG_3084 by jamie skinner, on Flickr

IMG_3084 by jamie skinner, on Flickr

Seller didn't exactly make it clear what was wrong but spare parts were available to buy.

On receipt of the nail gun turned out the piston which hits the nail had broken in two. Gutted! £130 for a new part. One of the worst parts to go!

Screenshot 2018-11-25 at 12.15.43 by jamie skinner, on Flickr

Screenshot 2018-11-25 at 12.15.43 by jamie skinner, on Flickr Unknown by jamie skinner, on Flickr

Unknown by jamie skinner, on FlickrSo I looked into a few ways of repairing it.

A few options:

Remove the hardened steel flat bar from the base and replace it with something else. Not sure if id actually be able to do it.

Buy a new one

Id recently remembered a 'This Old Tony' video on youtube about silver brazing. After some research seemed the way to go.

So this is how I did it:

(Please note I'm no metal worker, just going off that I thought would be a good idea.)

Its a nice clean break so I think im all good. I decided to add two grooves on either side to increase the surface area of the braze and to have some thicker parts of silver solder to brace the join. I used a magnet to hold the parts together while I used a Dremel cut off wheel on it. Also gave the parts a good clean with a wire wheel. Clean joints work best.

IMG_3035 by jamie skinner, on Flickr

IMG_3035 by jamie skinner, on Flickr IMG_3036 by jamie skinner, on Flickr

IMG_3036 by jamie skinner, on FlickrI brought a silver solder kit for £7 which was 55% silver with flux. I have access to a hearth but if not you could use a torch of some kind. Easily manageable in a home shop.

IMG_3037 by jamie skinner, on Flickr

IMG_3037 by jamie skinner, on Flickr Screenshot 2018-11-25 at 12.25.57 by jamie skinner, on Flickr

Screenshot 2018-11-25 at 12.25.57 by jamie skinner, on FlickrMixed the flux powder with water and applied to join. I applied both sides at once. From what I researched the silver will flow to wherever the heat and flux are. Heated to a red hot then applied silver to the joint. it flowed all the way around. Looked great. Then I think I did the next part right: I quenched it in water. As its hardend this should have kept it harder to a certain degree.. Think there is more science to it though!

IMG_3038 by jamie skinner, on Flickr

IMG_3038 by jamie skinner, on FlickrBrazed joint:

IMG_3039 by jamie skinner, on Flickr

IMG_3039 by jamie skinner, on FlickrNot the prettiest joint but seemed to work. I didn't really have anything to hold down the small piece so it moved ever so slightly when I brazed. Learnt something for next time!

IMG_3041 by jamie skinner, on Flickr

IMG_3041 by jamie skinner, on Flickr IMG_3042 by jamie skinner, on Flickr

IMG_3042 by jamie skinner, on FlickrLooking at where this goes in the nail gun the slightly thicker joint silver braze part clears everything so I left it as is to maintain as much strength as possible. I applied some friction reducer liquid I have to the channel it sits in.

One thing that concerned me was getting it brazed straight, as when this strikes the nail it sticks at some force! Any slight bend and it would problem crack.

So looks pretty good! Im surprised at how strong this is! (Famous last words maybe...)

IMG_3040 by jamie skinner, on Flickr

IMG_3040 by jamie skinner, on FlickrSo did it work? Well surprisingly yes!! Drove a 90mm nail into my floor. I have a deck to build next year so will put it through it paces then.

IMG_3082 by jamie skinner, on Flickr

IMG_3082 by jamie skinner, on FlickrI also painted it a metallic colour to differential between my other one. Gave it a good clean and service. Not bad for a total cost of repair and gun for £55.

Just found out the batteries don't hold a charge so next step is to replace those.

Thanks for reading. May be of some help for someone else.

IMG_3085 by jamie skinner, on Flickr

IMG_3085 by jamie skinner, on Flickr IMG_3084 by jamie skinner, on Flickr

IMG_3084 by jamie skinner, on Flickr