wallace

Established Member

Its been a little while since I did a resto thread, I have been busy though, I just finished an RS lathe but I've done a couple of threads on them so didn't bother again.

I was going to do a MF morticer but the courier curse struck and it ended up doing a somersault off the tail lift from a great height. I cant blame the driver too much because the seller had firstly attached it to a euro pallet which are totally unsuitable for top heavy lumps of iron, secondly he left the table wound up and motors raised.

The driver should have known better though, I never understand why they want to turn a pallet on the tail lift when it would be much easier to push it straight onto it then remove the pump truck, lower and put the truck back in from the front.

Anyway no one was hurt so that's the main thing.

I never knew 75Okg could bounce but it did, half pike double twist and back slap. This was a really nice machine amazingly no hand wheels broken

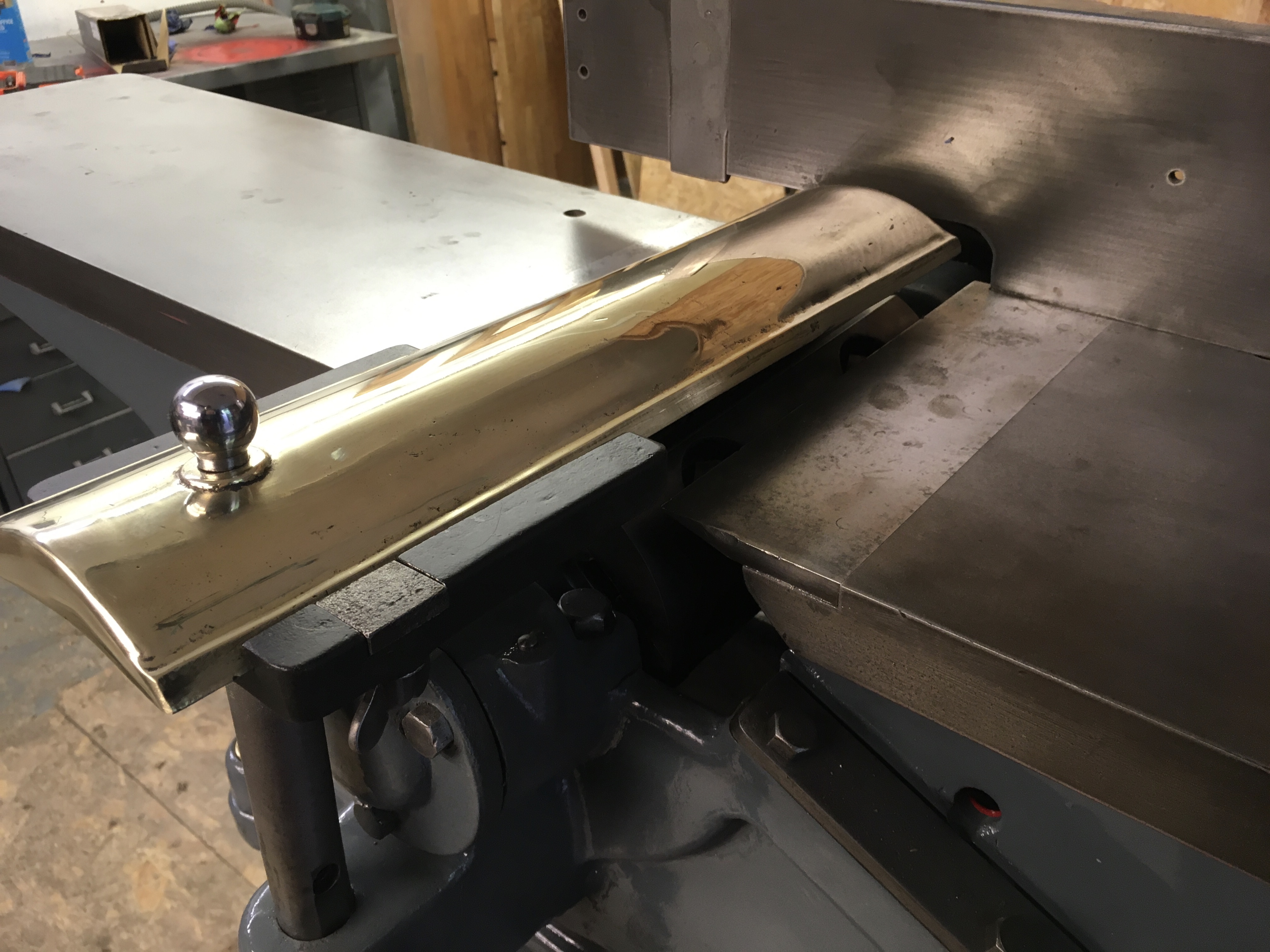

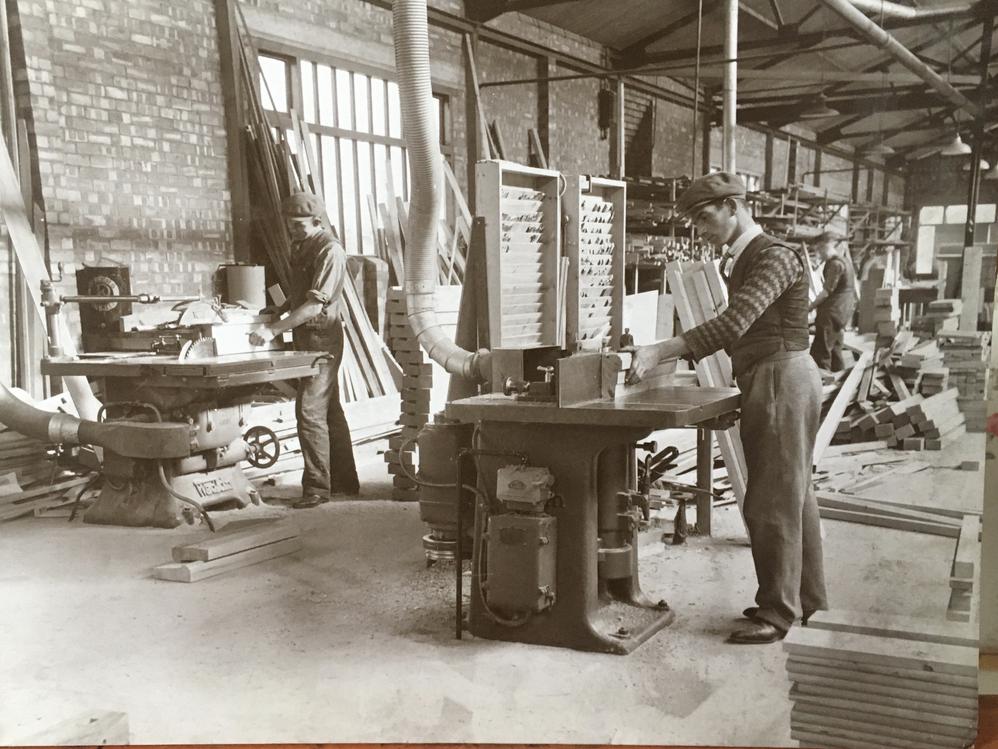

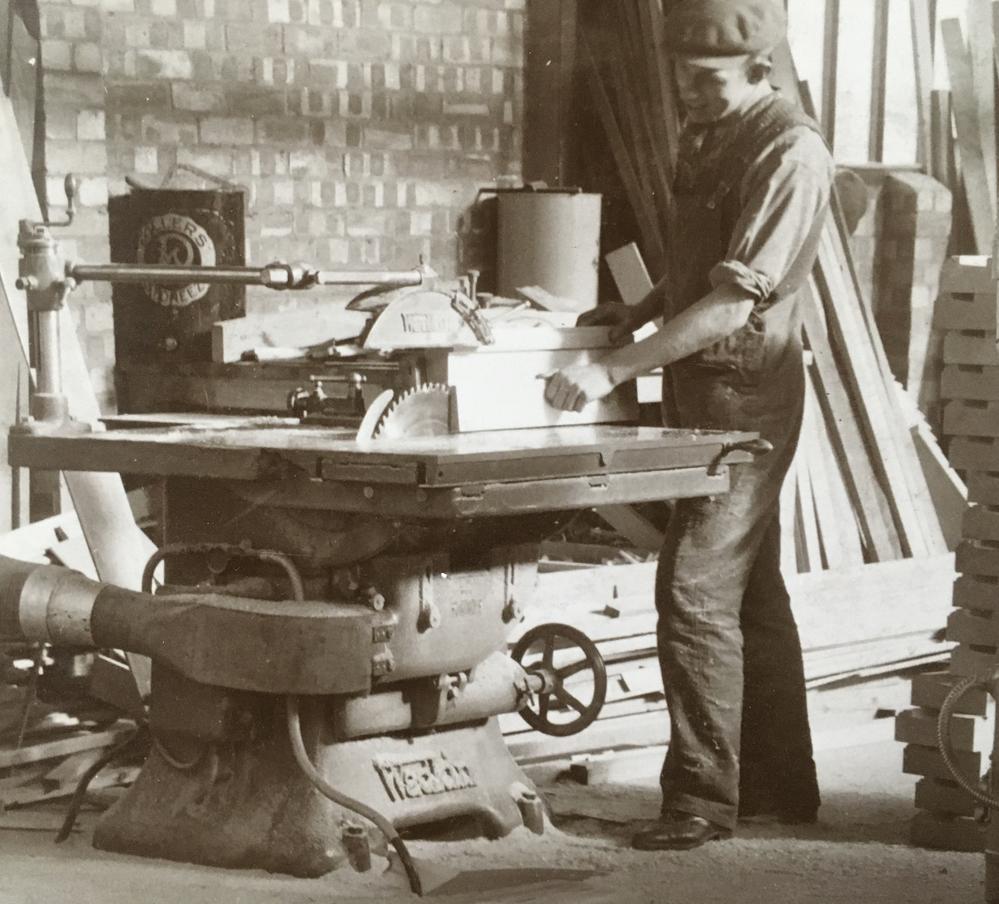

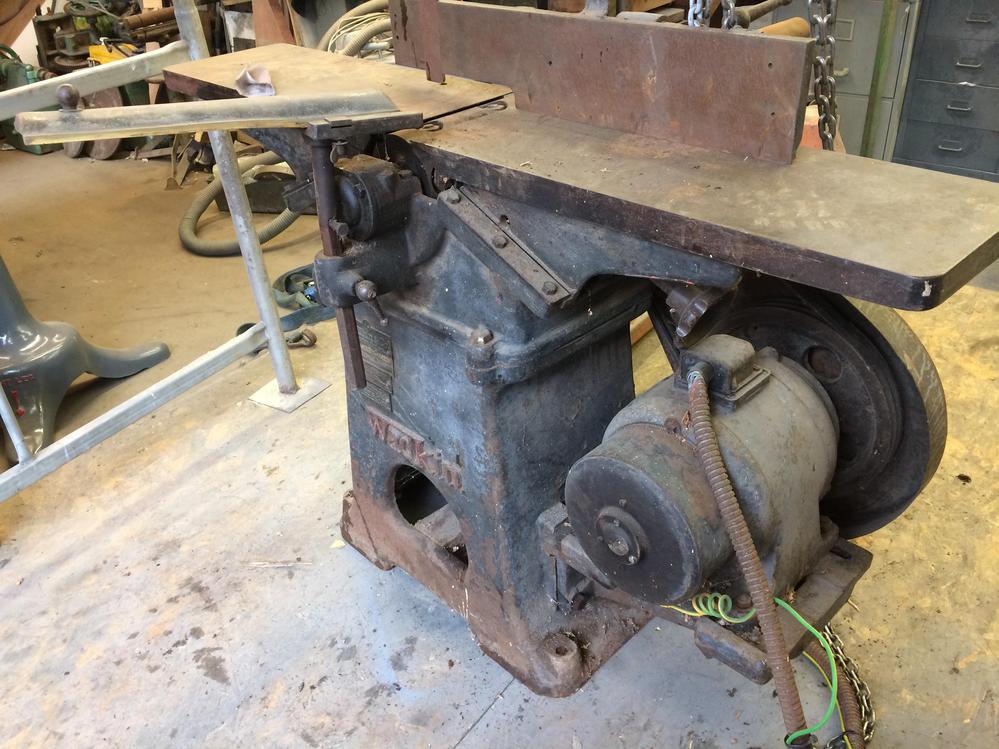

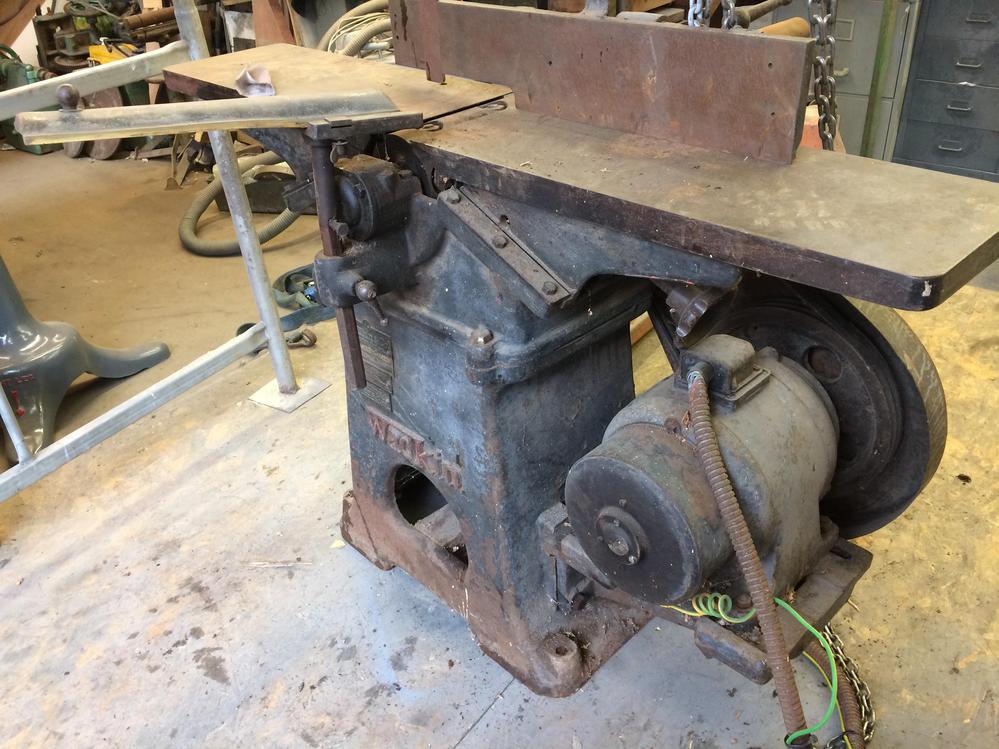

Heres the RB,

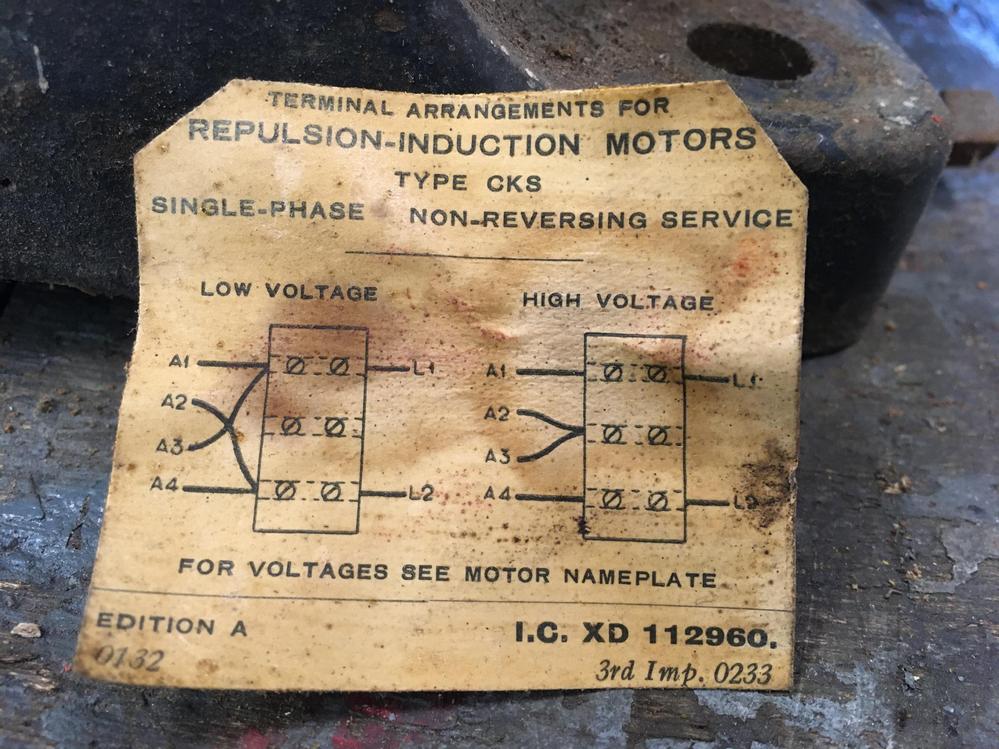

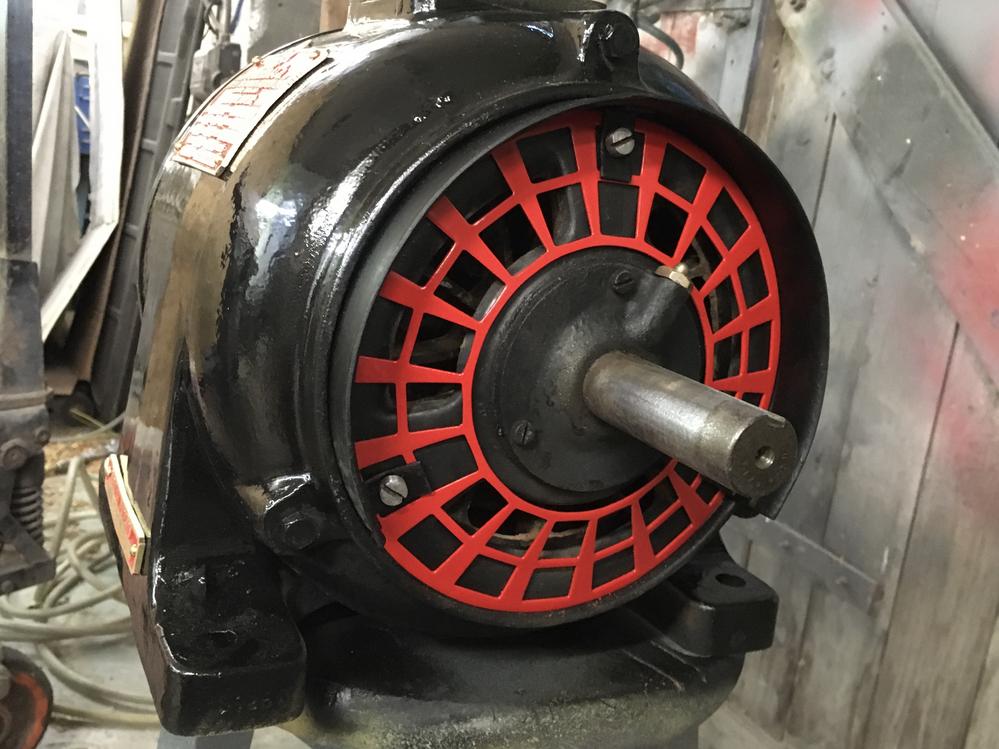

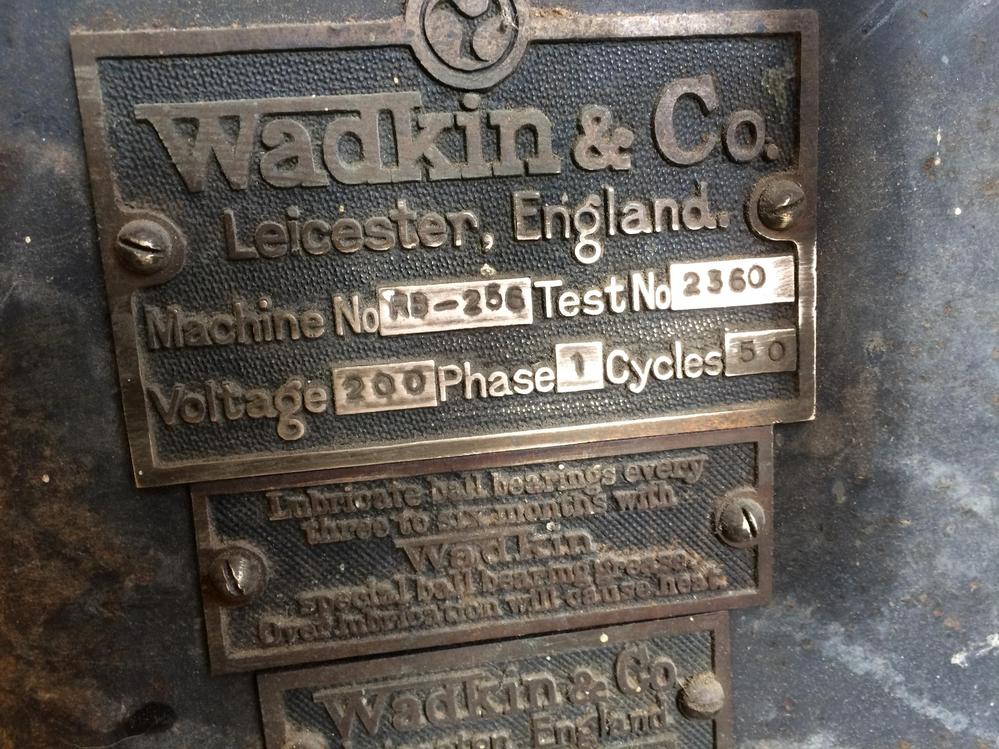

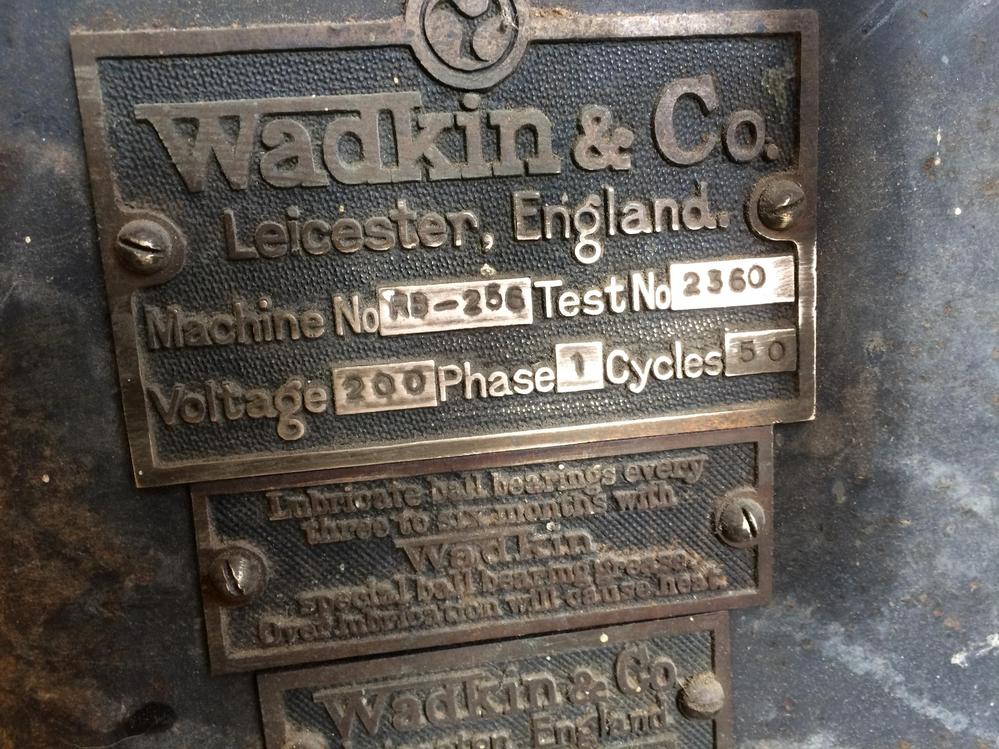

This is the first single phase wadkin I've come across and dates from 1934

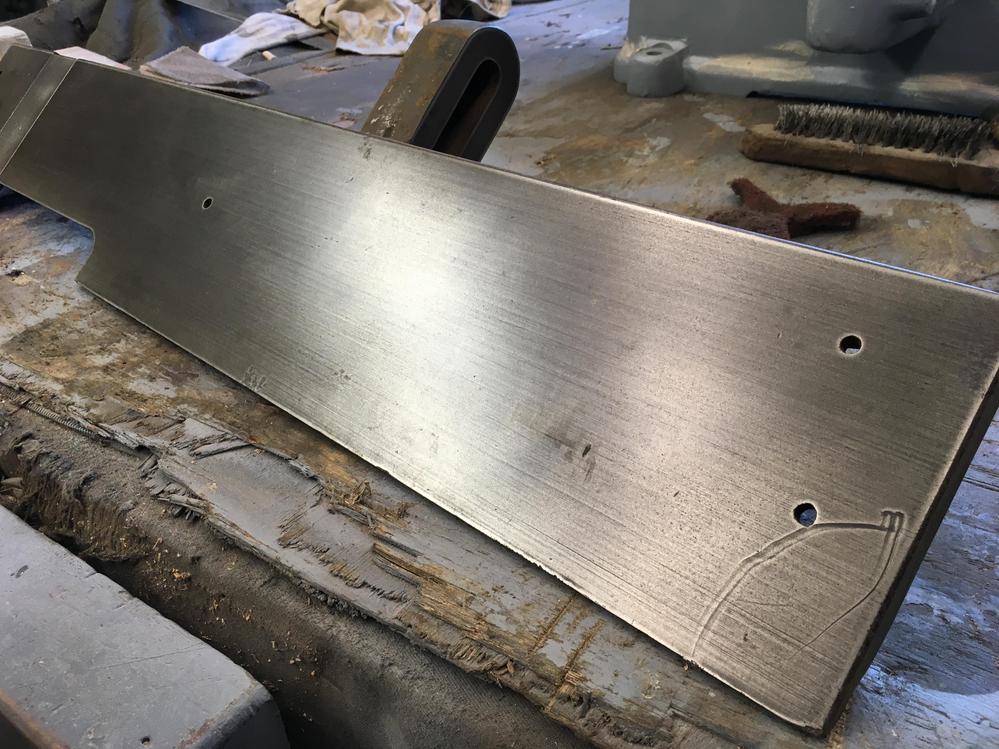

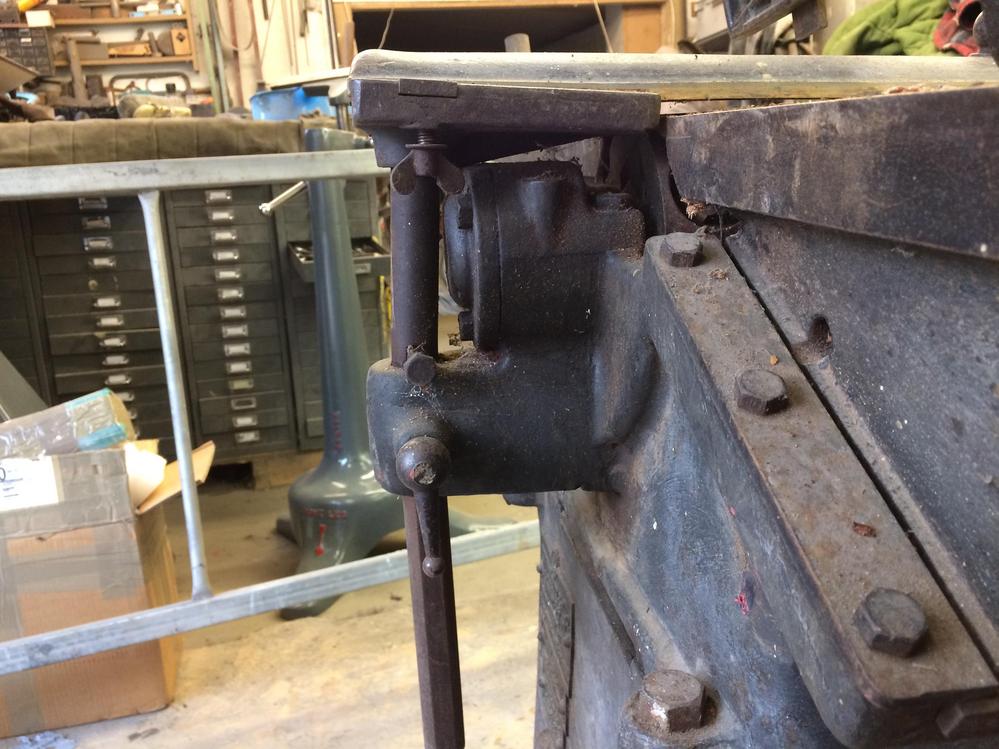

I asked the seller to lie it down to save the couriers a job in dropping it. Shame he didn't take the guard off first to stop damage

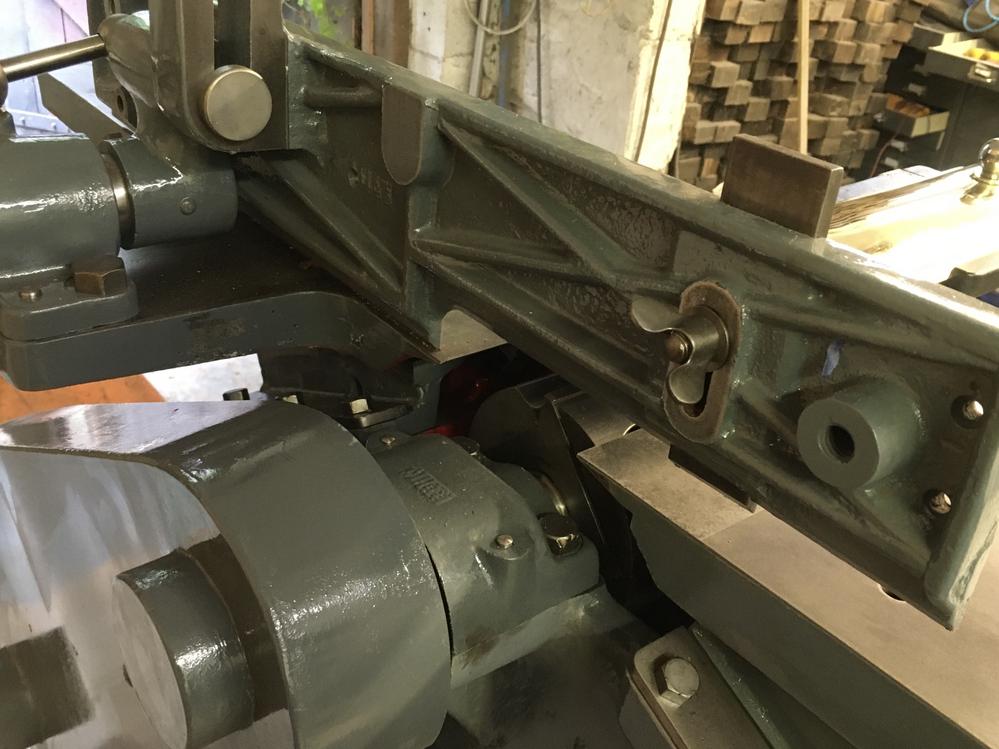

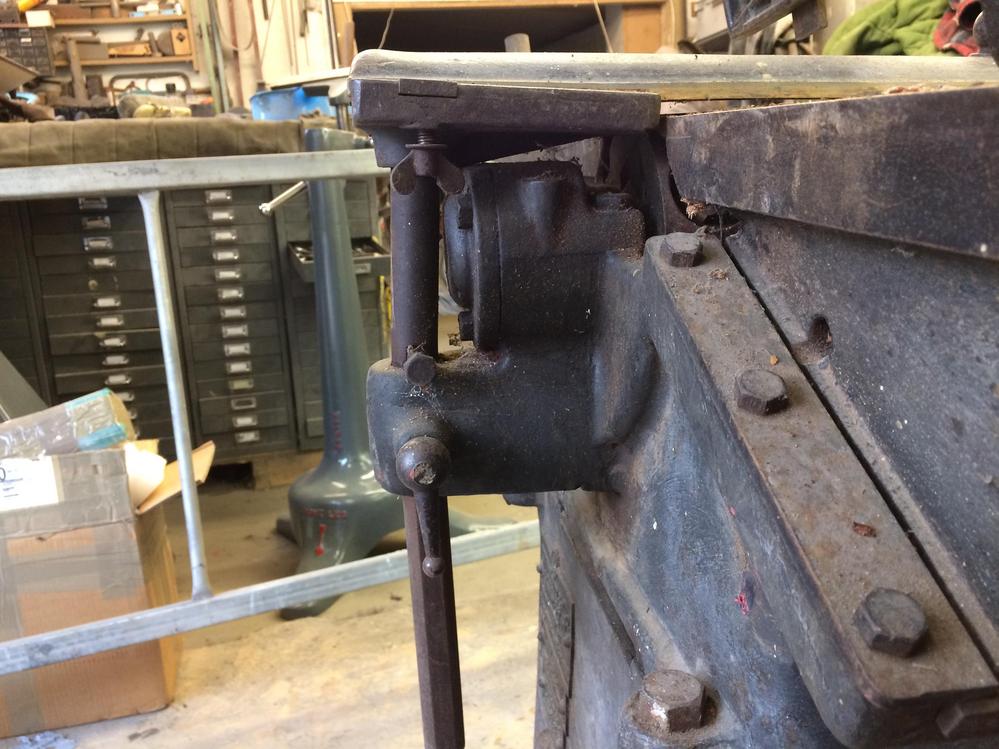

They are pretty simple things to strip down and within an hour it was in bits

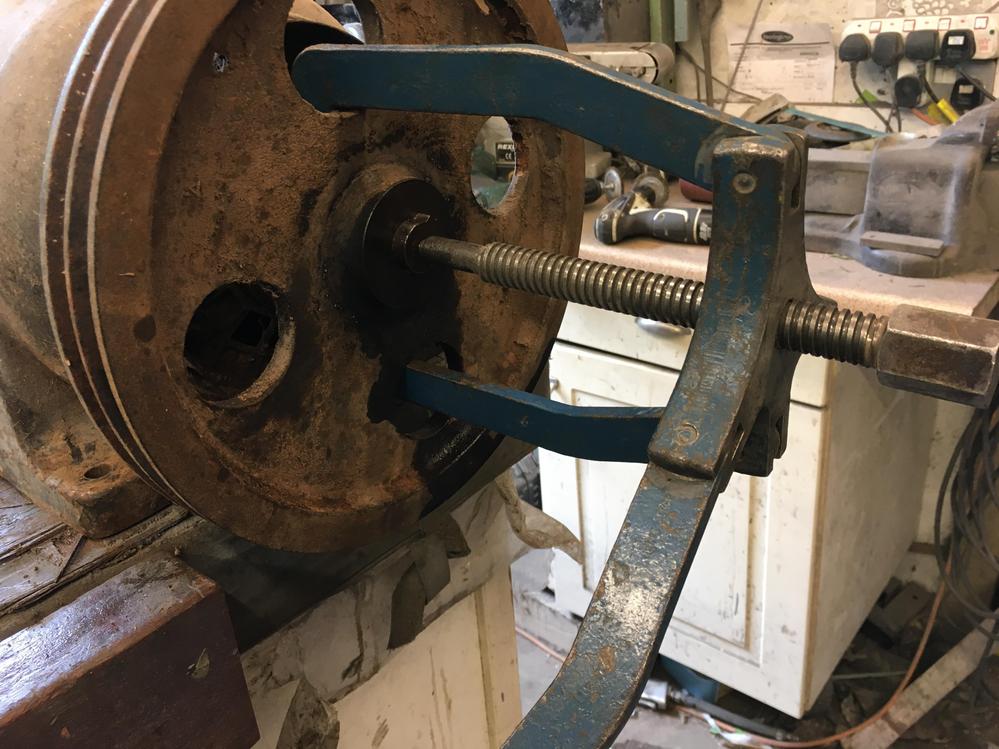

I maybe should have cracked the nuts whilst was on the machine.

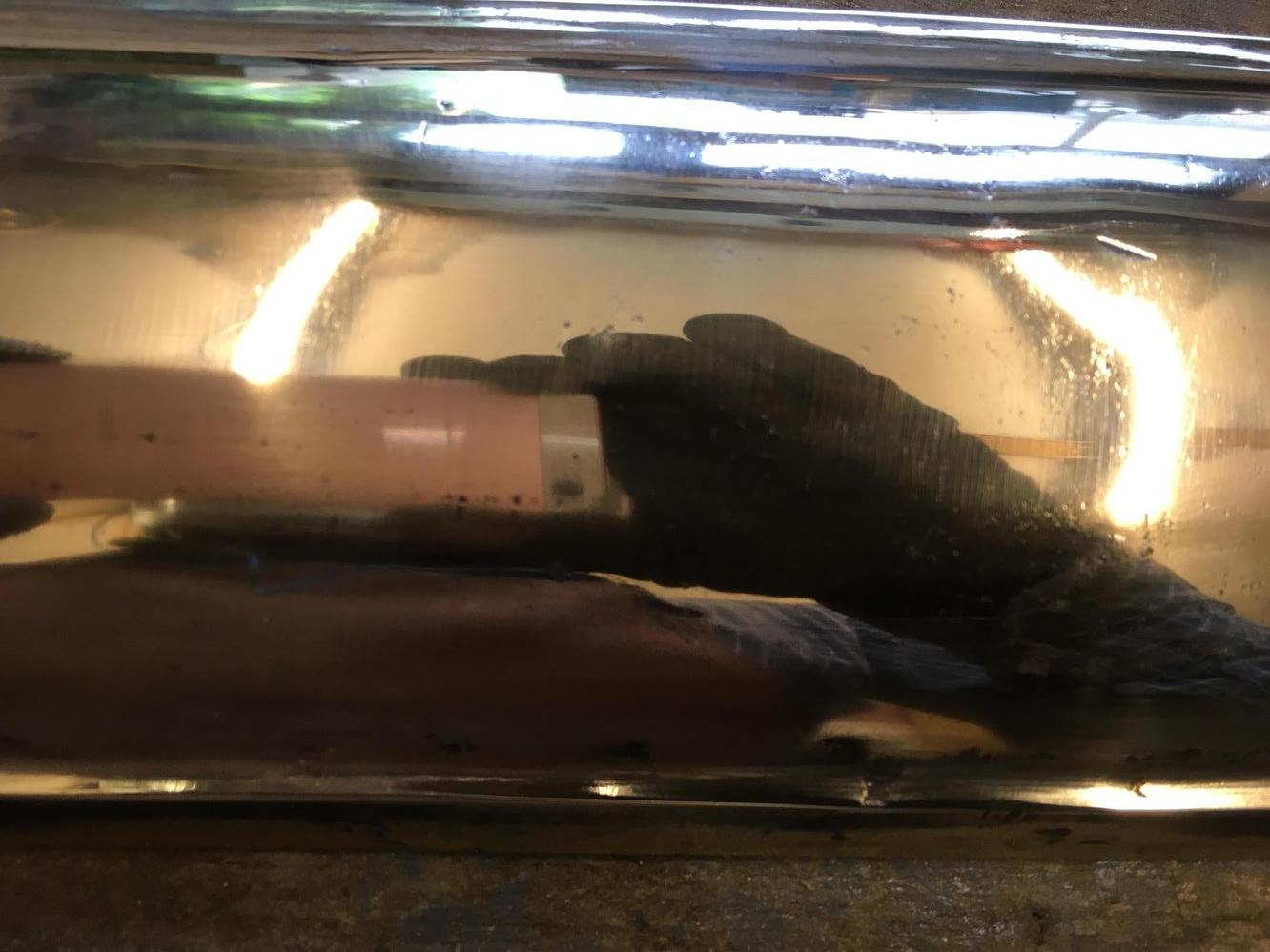

The nuts came off without too much force and I reversed the nut and screwed it back on to check for stretched threads. They screwed on smoothly so this machine has not been manhandled

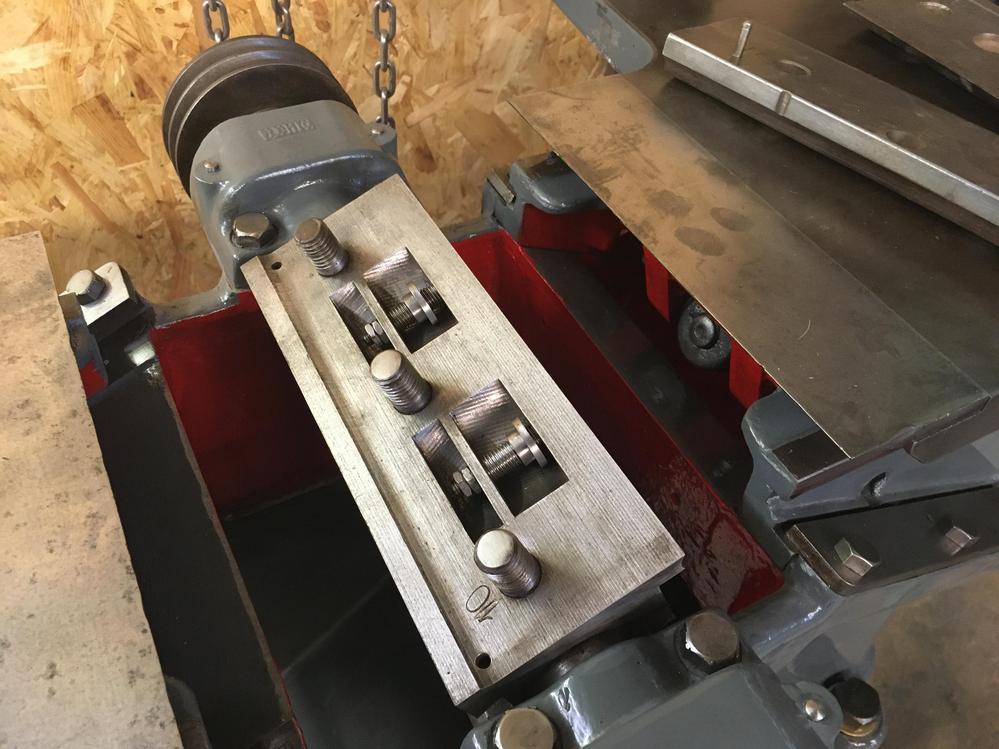

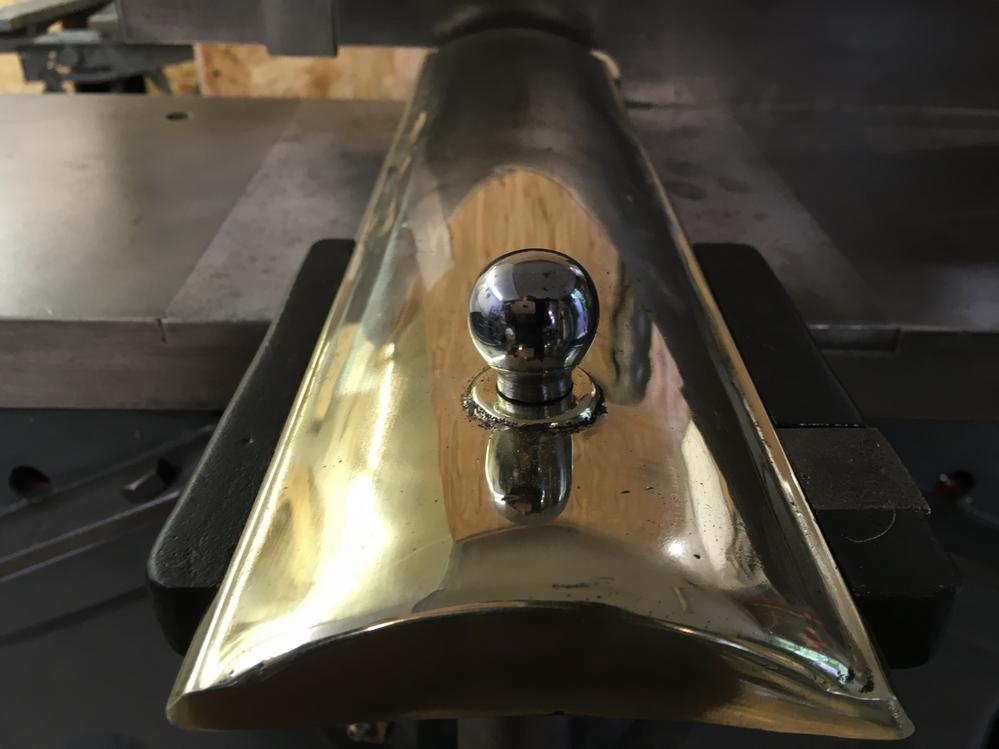

You can also remove two clam shells to run moulding irons

I've never come across split double row bearings before

I was going to do a MF morticer but the courier curse struck and it ended up doing a somersault off the tail lift from a great height. I cant blame the driver too much because the seller had firstly attached it to a euro pallet which are totally unsuitable for top heavy lumps of iron, secondly he left the table wound up and motors raised.

The driver should have known better though, I never understand why they want to turn a pallet on the tail lift when it would be much easier to push it straight onto it then remove the pump truck, lower and put the truck back in from the front.

Anyway no one was hurt so that's the main thing.

I never knew 75Okg could bounce but it did, half pike double twist and back slap. This was a really nice machine amazingly no hand wheels broken

Heres the RB,

This is the first single phase wadkin I've come across and dates from 1934

I asked the seller to lie it down to save the couriers a job in dropping it. Shame he didn't take the guard off first to stop damage

They are pretty simple things to strip down and within an hour it was in bits

I maybe should have cracked the nuts whilst was on the machine.

The nuts came off without too much force and I reversed the nut and screwed it back on to check for stretched threads. They screwed on smoothly so this machine has not been manhandled

You can also remove two clam shells to run moulding irons

I've never come across split double row bearings before