Steve Wardley

Established Member

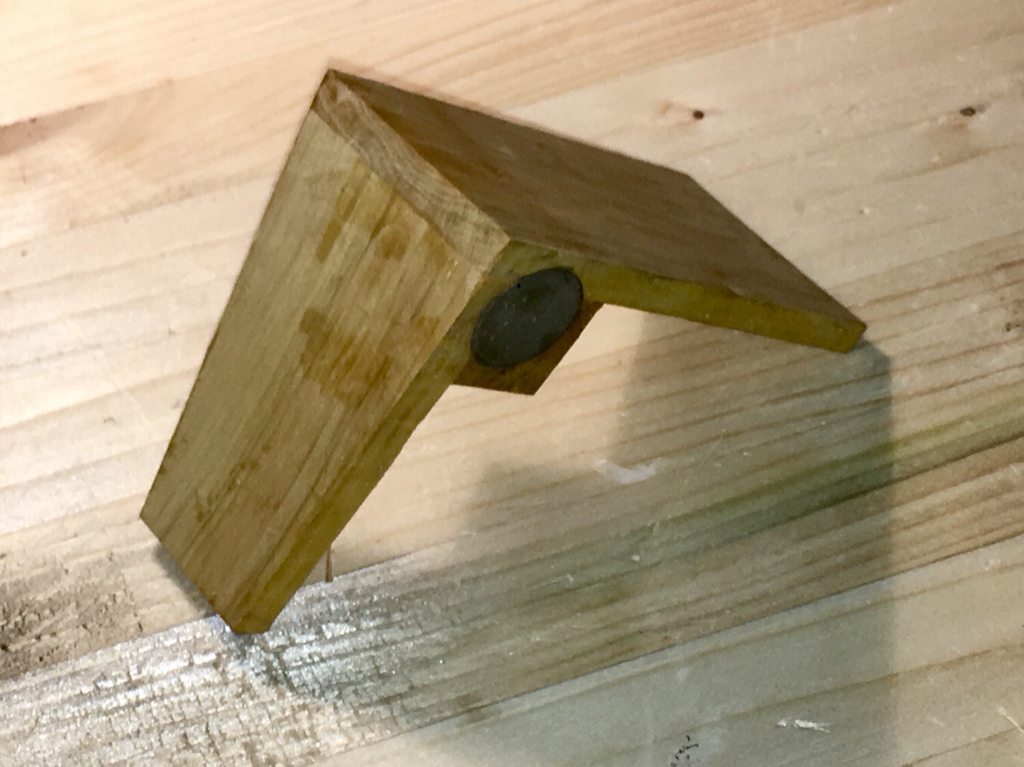

Maybe a silly question I know but a friend and I were discussing dovetail joints and he asked me how many DTs do you build into a given size of board and I couldn't tell him other than just how many looks pleasing to the eye.

That then prompted me to ask is there a rule of thumb for how many you would cut into say a 6" deep drawer because let's face it you could go from one or two up to twenty or more if you are brave.

Is it just aesthetics or is there an issue of joint strength that would make you cut X per inch ?

Cheers all, Steve

That then prompted me to ask is there a rule of thumb for how many you would cut into say a 6" deep drawer because let's face it you could go from one or two up to twenty or more if you are brave.

Is it just aesthetics or is there an issue of joint strength that would make you cut X per inch ?

Cheers all, Steve