update as of tonight, built the last drawer 2 days ago and glued it up, installed it this evening :

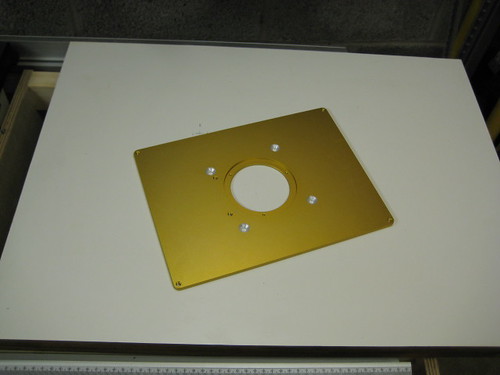

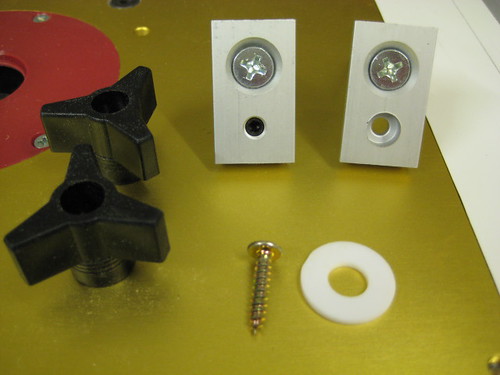

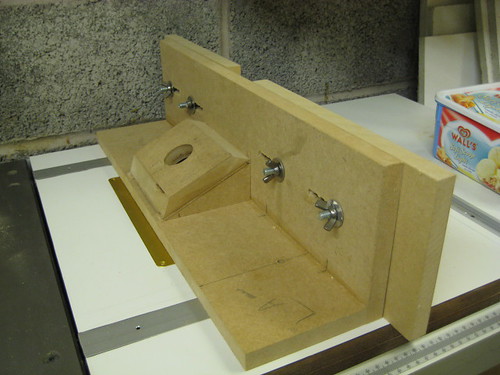

Rich you asked about the mounting for the router table, some pictures which I hope will help (if not let me know and I'll try some different angles), like i said its a pretty simple method of the top sat on the cabinet sides with a couple of rails across, then used screws to level it all off :

Jobs to finish the unit off are :

1. route the cables through the cabinet (tidy them up)

2. Build a door for front of router section (perhaps with storage built into it)

3. put a back on it and some dust extraction under the router table

4. Build a fence for it

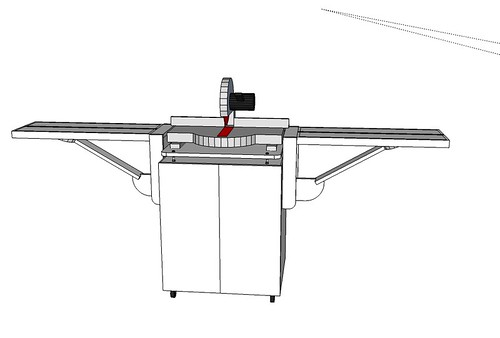

The onto a cabinet for my enormous Mitre saw (Bosch 12 inch sliding compound) as at the moment on the stand that came with it its too big to fit in the shop !

Rich you asked about the mounting for the router table, some pictures which I hope will help (if not let me know and I'll try some different angles), like i said its a pretty simple method of the top sat on the cabinet sides with a couple of rails across, then used screws to level it all off :

Jobs to finish the unit off are :

1. route the cables through the cabinet (tidy them up)

2. Build a door for front of router section (perhaps with storage built into it)

3. put a back on it and some dust extraction under the router table

4. Build a fence for it

The onto a cabinet for my enormous Mitre saw (Bosch 12 inch sliding compound) as at the moment on the stand that came with it its too big to fit in the shop !