babylon355

Established Member

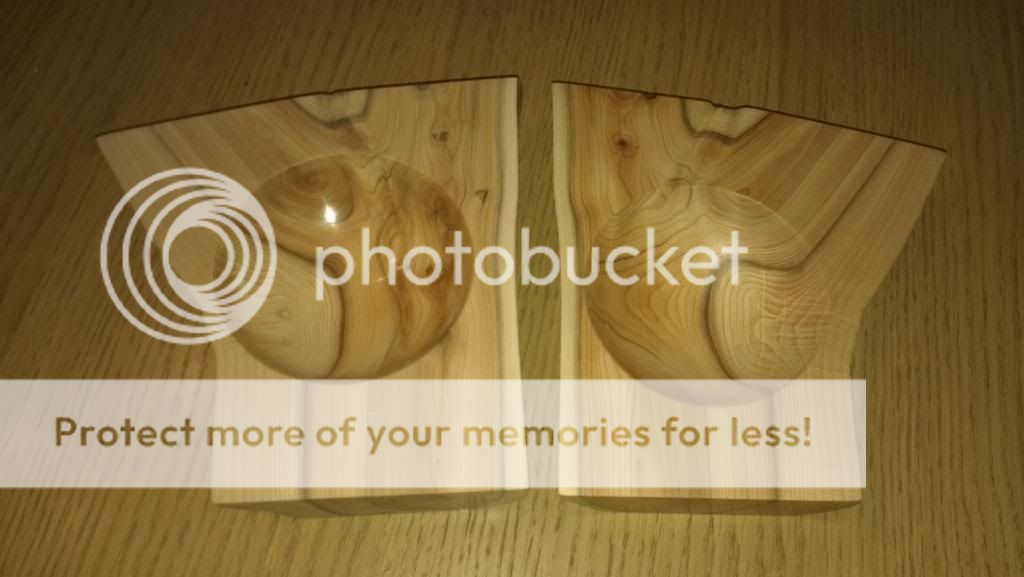

Have been busy in the garage making pens, bowls, tea lights, reindeers and all manner of things in readiness for the craft fayre season and had a piece of yew left over. Got the guard on the trusty Startrite up and ran it through to make two matching halves. Made one last night and the other today but forgot I'd left the one last night natural and put some friction polish on the centre of the one today (old age for you!)

I'll probably get the Chestnut mops out and sort them out tomorrow but happy with the look.

Roughly 6 inches by 5 and 1 1/2 high.

I'll probably get the Chestnut mops out and sort them out tomorrow but happy with the look.

Roughly 6 inches by 5 and 1 1/2 high.