Richard T

Established Member

I though I should have maybe put this in the Tool Review Dpt. but as I couldn't do a proper review as it's too dull to take photos without flash, that and I couldn't wait, I'll put it here.

After a long wait of just over 24 hours after paying for it - how does Matthew do that? - this big, heavy parcel turned up.

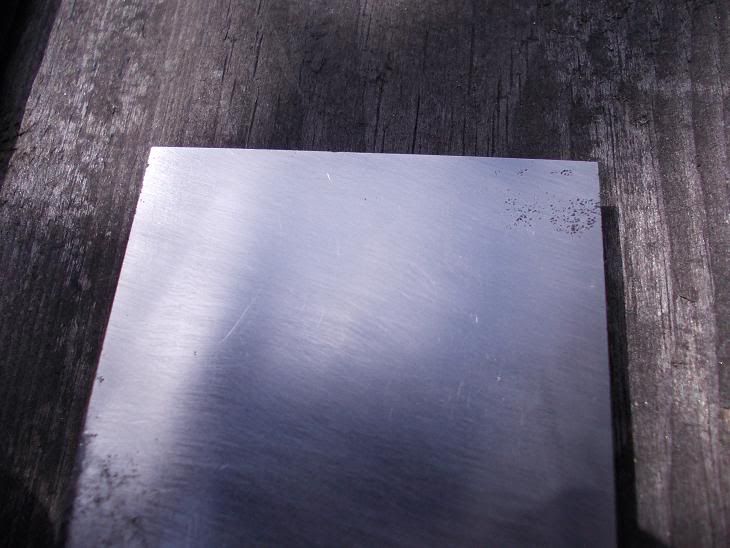

And this was what was inside:

An Extra, extra coarse diamond stone - 120Grit.

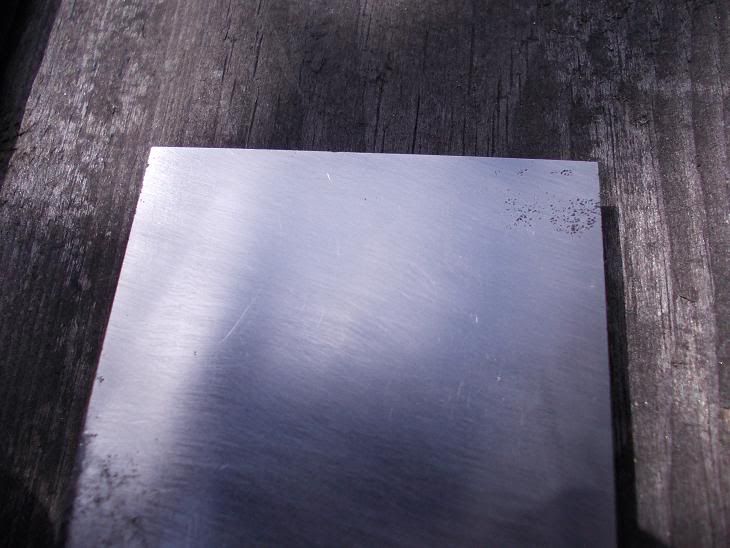

This is when the sun went in and I couldn't get decent pictures but this is a narrow J. Sorby iron that had some moderately bad pitting on the face - I've already started here and discovered it is also somewhat convex.

The duration of today's "Bargain Hunt" and it's nearly done.The sun has re appeared so here is another photo.

Here I have taken off the diamond scratches with an oil stone and there are still some traces of the pitting but it will more than do, because by the time it gets back there it will have been stoned flat; and there is still the tiniest dink in the edge. But it's nearly there in 45 minutes. :shock: This would have taken me several evenings with emery cloth stuck down to board and several changes of cloth and tape.

It was very expensive but I am more than chuffed with it. Those bootsale chisels and irons will no longer be the work of weeks. I might even knock me up one of Jacob's flattening handle specials to take away the finger strain.

After a long wait of just over 24 hours after paying for it - how does Matthew do that? - this big, heavy parcel turned up.

And this was what was inside:

An Extra, extra coarse diamond stone - 120Grit.

This is when the sun went in and I couldn't get decent pictures but this is a narrow J. Sorby iron that had some moderately bad pitting on the face - I've already started here and discovered it is also somewhat convex.

The duration of today's "Bargain Hunt" and it's nearly done.The sun has re appeared so here is another photo.

Here I have taken off the diamond scratches with an oil stone and there are still some traces of the pitting but it will more than do, because by the time it gets back there it will have been stoned flat; and there is still the tiniest dink in the edge. But it's nearly there in 45 minutes. :shock: This would have taken me several evenings with emery cloth stuck down to board and several changes of cloth and tape.

It was very expensive but I am more than chuffed with it. Those bootsale chisels and irons will no longer be the work of weeks. I might even knock me up one of Jacob's flattening handle specials to take away the finger strain.