bugbear":i8ynyepi said:

Adding fit + finish will make a nicer intrinsic object, but not (as far as I can judge) a better honing guide.

Sometimes the bed on the Eclipse-style guides is not flat - the two halves can be at different levels or they can ride up when the guide is tightened up. This can be cured with a little work with a file. Also, the slots used to hold bevel-edge chisels can cause problems because of the variability of chisels.

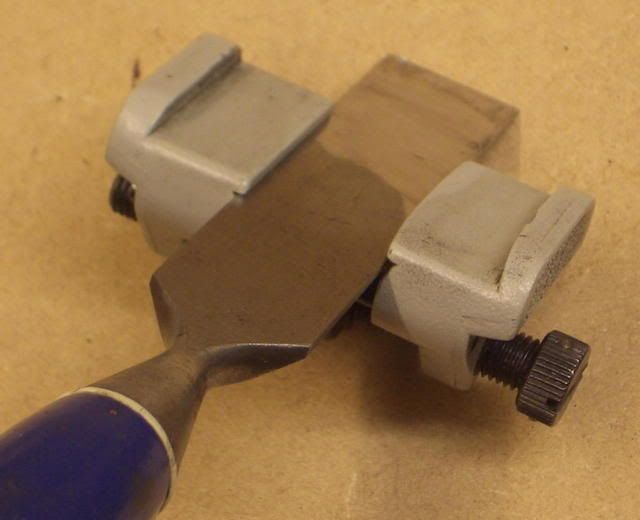

When used for chisels, the tool is normally gripped like this

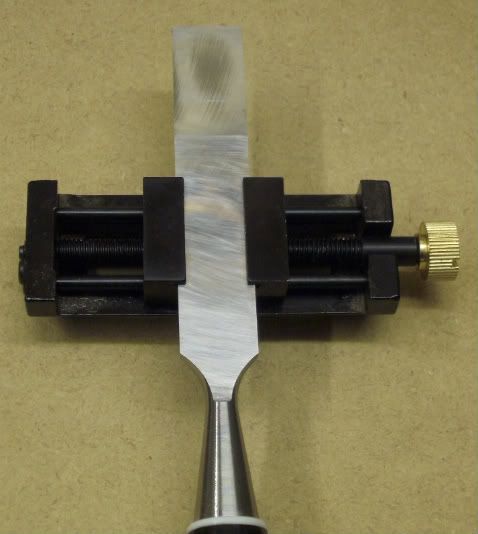

A better arrangement can be had by modifying the guide so that the chisel registers off the flat side, like this

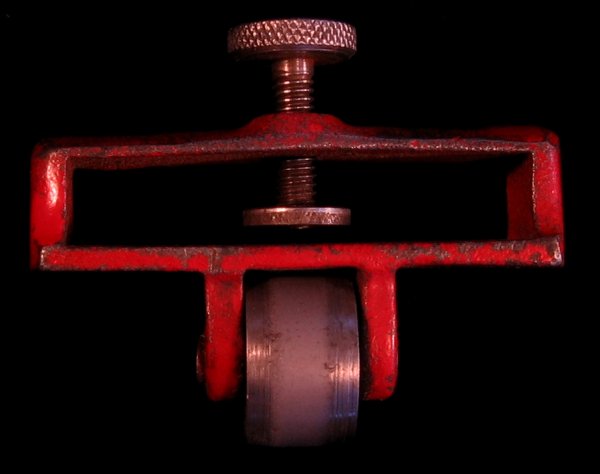

For chisels, I now use the Trend guide, which registers off the flat side of the chisel like this (excuse the state of the chisel - it's new and I'm still flattening and polishing the back)

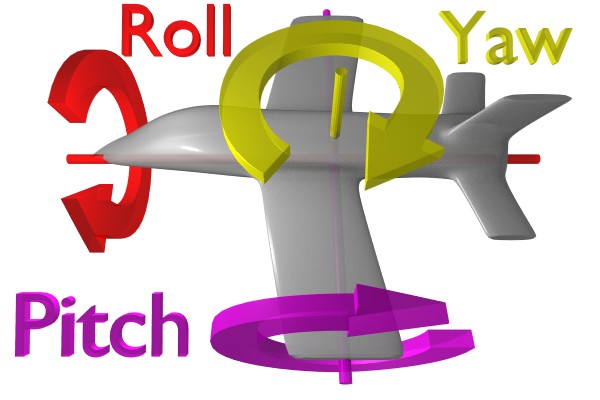

It also has a much wider roller than the Eclipse

I found that while the narrow Eclipse roller is good for honing cambers on plane blades, it can cause problems when honing chisels. If I didn't concentrate hard I found that I was often honing a skew shape on the chisel. With the wide Trend roller just hone away and the end comes out dead square

The Trend guide isn't perfect, though. Pig sticker chisels are too deep to fit in it and even some bevel-edge chisels (the largest of the Lie Nielsen's, for example,) are too deep to fit. Overall, though, for chisels I'm finding it the best of the guides.

Cheers :wink:

Paul