GEPPETTO

Established Member

Hi All,

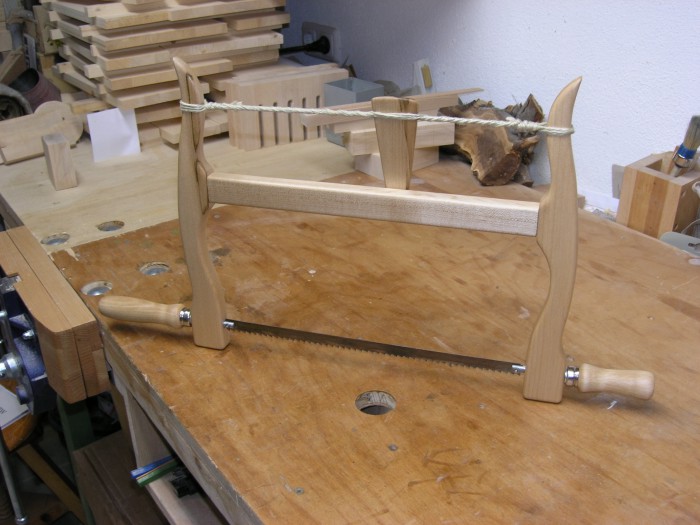

I have took the want to build a bowsaw. Well, Do you have any advices where I can find the blades?

I have took the want to build a bowsaw. Well, Do you have any advices where I can find the blades?

Ermmm.... Think it was SCOTT who posted that one. I've seen fleam-tooth blades used in a couple of German joinery shops where the blade cuts in both directions. They're used to saw down a tenon and cut really quickly. I believe the blades are made by either Eberle or Kunz and that type of saw is certainly made by both Ulmia and ECE Emmerich (Primus)Midnight":26mhr1z0 said:Scrit... would those blades be suitable for building a resaw?? Same idea *sorta kinda) as the bow saw but with 2 streachers and a central blade...??

Enter your email address to join: