tomthumbtom8

Established Member

You may remember last week a bought a sterling 1000 lathe

And I would like to turn pens on it or at least sand and polish pens

well I shouted out for a chuck and the chuck has arrived and now I'm waiting for a mandrel to arrive this is the one

http://www.ebay.co.uk/itm/300689356169? ... _500wt_969

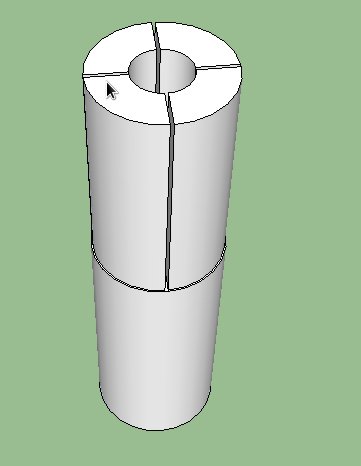

But I looked on the masterchuck 2 web site and the smallest jaws only close to 3/8 which I think is around 9.5mm

and a mandrel is 7mm

I would like to know what to do now and how do I get around this (I said I would make some pens for Christmas (me and my big mouth it would have been cheaper to buy the pens))

My lathe shaft is 3/4 16 unf

Tom

And I would like to turn pens on it or at least sand and polish pens

well I shouted out for a chuck and the chuck has arrived and now I'm waiting for a mandrel to arrive this is the one

http://www.ebay.co.uk/itm/300689356169? ... _500wt_969

But I looked on the masterchuck 2 web site and the smallest jaws only close to 3/8 which I think is around 9.5mm

and a mandrel is 7mm

I would like to know what to do now and how do I get around this (I said I would make some pens for Christmas (me and my big mouth it would have been cheaper to buy the pens))

My lathe shaft is 3/4 16 unf

Tom