Mr_Grimsdale":2sa1s52z said:

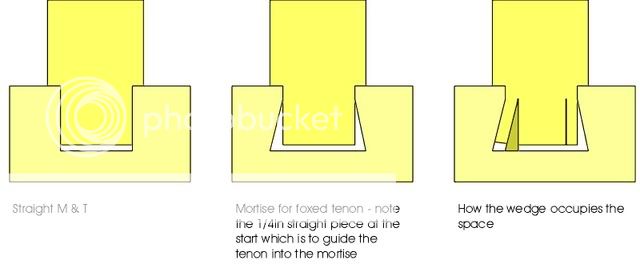

BTW the "foxed" tenon is a way of getting a very firmly keyed fixing in a stopped mortice. For a through mortice a foxed tenon is used decoratively, but is likely to be weakened by virtue of the bending outwards of the tenon edges and risk of breaking. Normal edge applied wedges are going to be stonger and easier to perform.

cheers

Jacob

I have to disagree. In Percy Blandfords 'Practical Carpentry' it states:

"Through tenons may have wedges driven outside them. This tigtens by compressing the tenon, which is not as efficient as spreading it."

It also goes on to explain about 'fox' wedges being applicable only to stubb or blind tenons.

OOh, get me: qouting from a book! :lol: