Tucker

Member

Looking mint as usual. Wadkins are so hard to find here in nz

...Wadkins are so hard to find here in nz

Presumably you have plans to use it to turn a few small items, such as pepper mills or a few commemorative platters, something like that? After all, you wouldn't want to tax the machine beyond it's capacity, ha, ha. Slainte.This is the last machine in my bucket list so is a keeper.

I've always fancied doing one of those huge hollow forms, I know a guy called vince manna in Oz who made them big enough to fit a person.Perhaps pen turning? Maybe keyrings?

You gotta eat your spinach lolHow do you get the bed to slide over ?

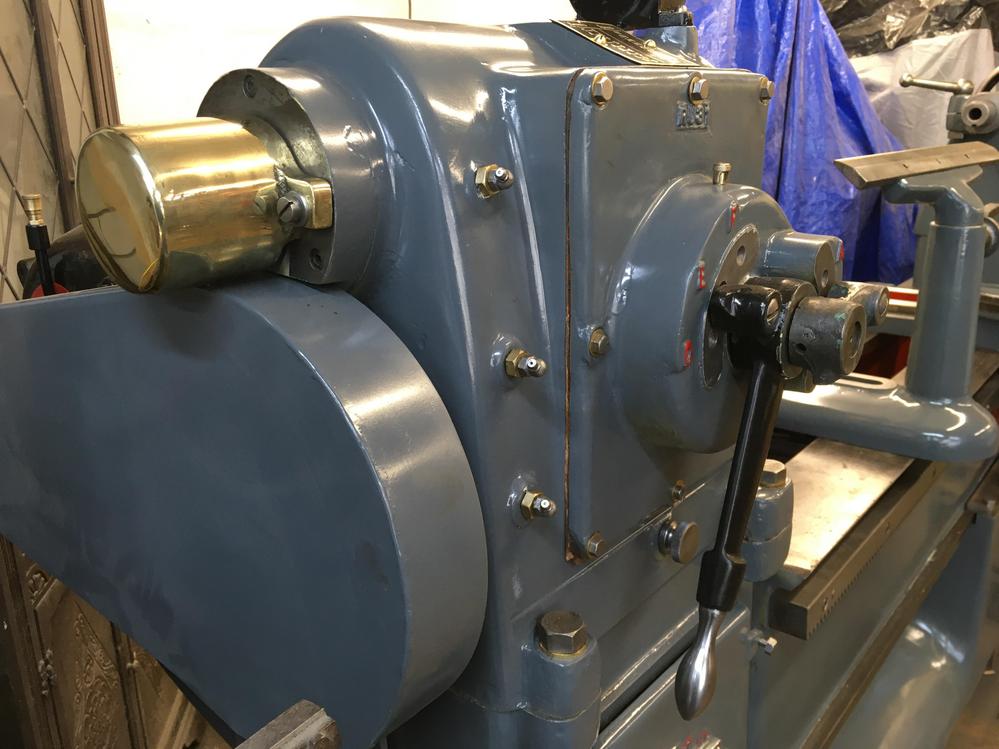

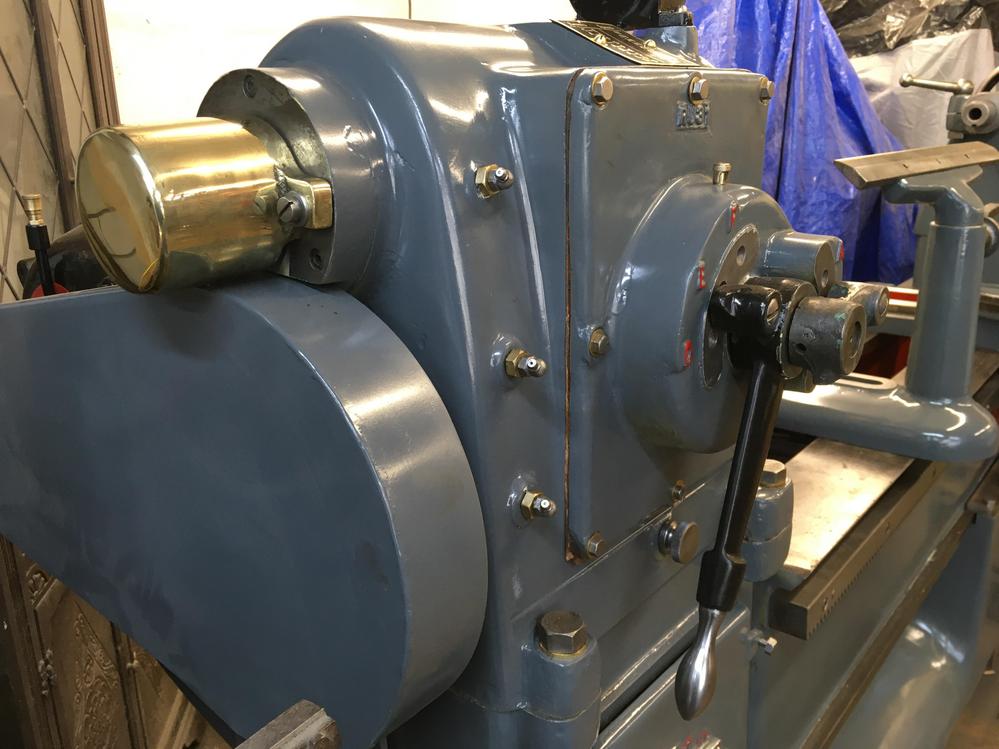

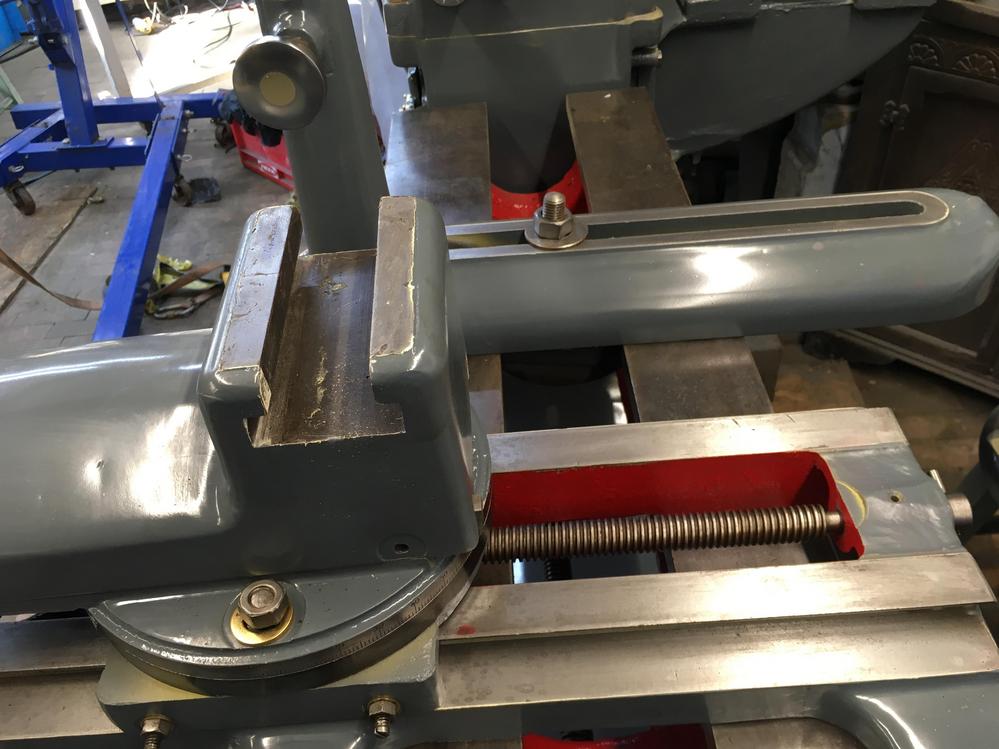

That bit john repaired attaches to the bed and houses 2 gears, one goes to a handle which is wound by the operator, the other is on the end of a long screw which goes through a threaded plate attached to the headstock. I reckon the whole lathe would have to be well levelled for it to work easily.How do you get the bed to slide over ?

Fantastic refurbishment. Have you enough work for it to be kept busy full time? Cheers Tony

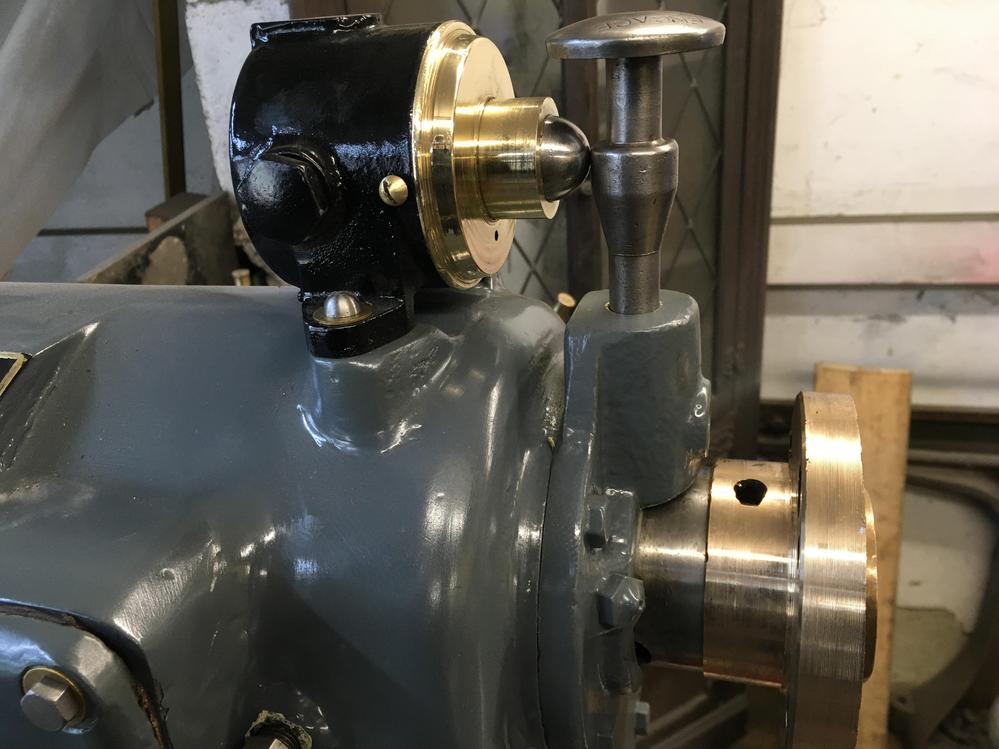

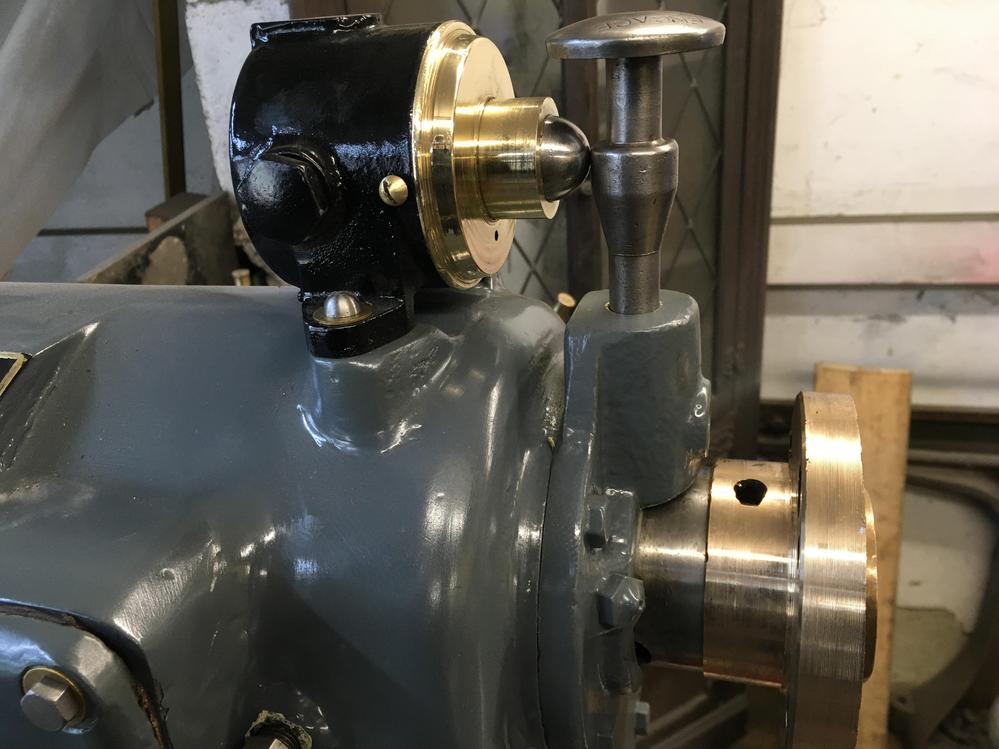

The brass was a bit dinged up so I gave it a skim

I've been removing masking tape and assembling bits all week. On some bits the tape had left its adhesive on the metal, was a right pain to remove even with thinners. I've not had this problem with frog tape before.

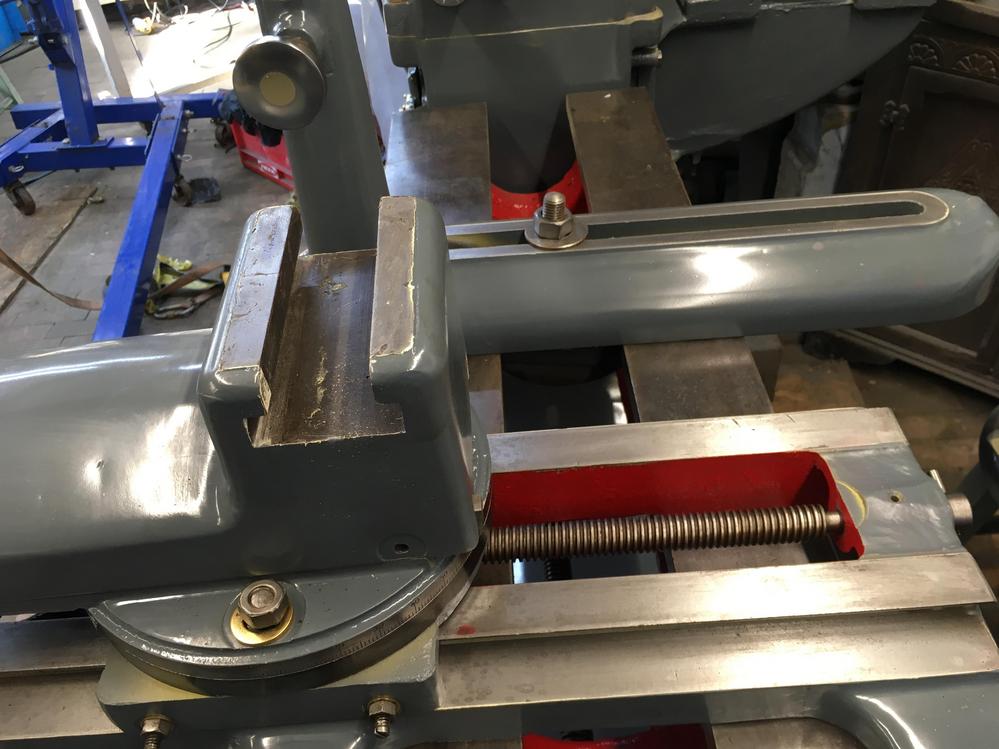

I went over the surfaces with oil stone to remove any dings on the ways. every machined surface has been hand scraped when it was built.

This was what had been used to lock the tool rest. I have a proper lever but it needs drilling and tapping for 3/4".

I found this in my stash

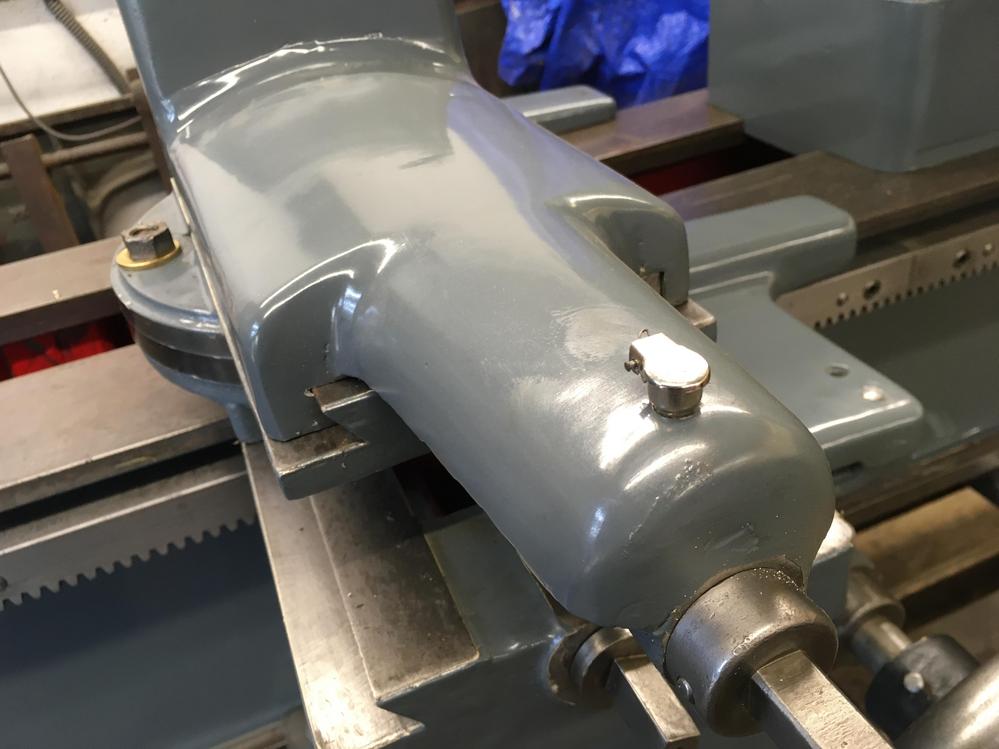

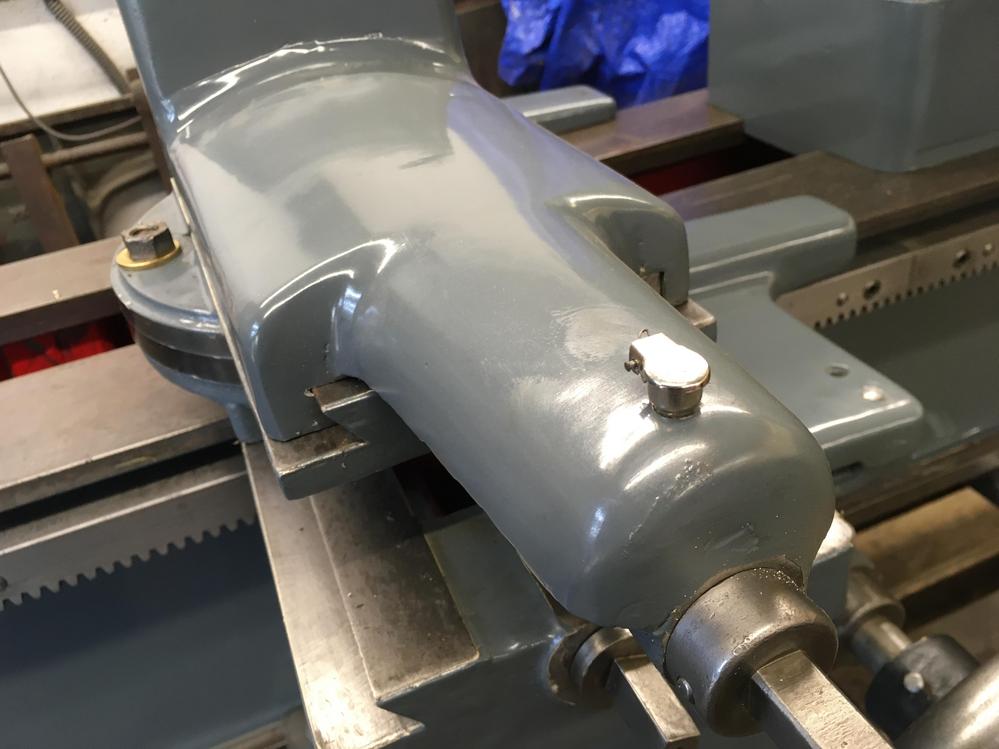

The cover for the outboard spindle, sanded to 240

Then buffed

The spindle interlock

New flip top oilers

Enter your email address to join: