Well the BAO/S is a 1966/67 machine according to my information.Simon":20vw5m4y said:The test number for the BAOS is 661536 and the RAA data is RAA552 test number 6806. Any info would be great.

The RA predates the test number sequencing adopted in the late 1940s and so is probably a 1936 to 1942 period machine, partly because the brass name plates were replaced by steel ones during WWII and by ally ones thereafter, although by the late 1940s Wadkin did revert to cast brass plates on some machines. The other clue is the nomenclature. Prior to WWII Wadkin used to give their machines two letter names in the main, hence RA, RB, LS, EP, etc. The third letter would indicate the power source, e.g. "A" means AC motor, "D" means DC motor drive and no suffix meant that either there was no choice (i.e. the machine only came in AC motor or lineshaft drive method) or that the machine had been supplied sans motor and/or switchgear. Sometime around WWII or possibly shortly after the suffix letter for motorised machines was dropped as lineshaft/belt drive was by then disappearing fast (Wadkin's last full-line catalogue to list them was actually in the 1930s although individual brochures did list them much later) and DC motors were available to special order only. That's why I referred to your machine as an RA. Incidentally the first letter referred to the "family" of machines - "R" machines were always planers, thicknessers or planer/thicknessers (e.g. RA, RB, RD, RE, RM, RZ, etc), "S" machines were all rip saw benches (e.g. SO. SP, SR, SS, SW, etc), "P" machines were all precision saw benches (e.g. PK, PP, PU, etc), "D" were all bandsaws (e.g. DE, DR, DS, etc), "L" were all pin routers, borers or recessors (e.g. LE, LS, LL, LM, LQ, etc) and so on.

BTW, purely indulgence on my part, but here's my LQ, just after delivery :lol: :

The colour is apparently what Rolls-Royce used to paint all their pattern shop machines in - much like ex-BAe Systems Wadkin machines are often to be found painted SCM desert sand..... yuk!

Things started to get a lot more confused after the Sagar/Bursgreen buy-out occurred with some machines originally built a Wadkin in Leicester being transferred to Bursgreen, Durham or Trawden and given a "B" prefix (e.g. LM borers became BLMs), some Sagar designs being retained to replace the older Wadkin designs and also getting a "B" prefix in front of the original Sagar name, e.g. the 6in BFS started life as a Sagar FS (and incidentally was the machine which replaced the Leicester-built RA small planer). Some machines even got odder names, like the AGS table saw (although there was also a BGS) and the MZC/MZF/MZM "family" of band saws. What was that all about?

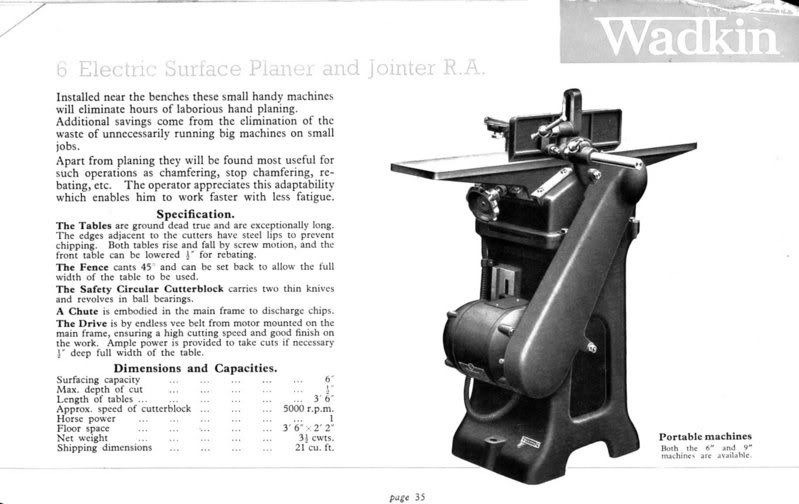

I have some data from the period. This is an RA in the 1949 Wadkin catalogue:Simon":20vw5m4y said:Do you have any original info on the RAA? .... I have never seen any.

Good enough?

Scrit