wallace

Established Member

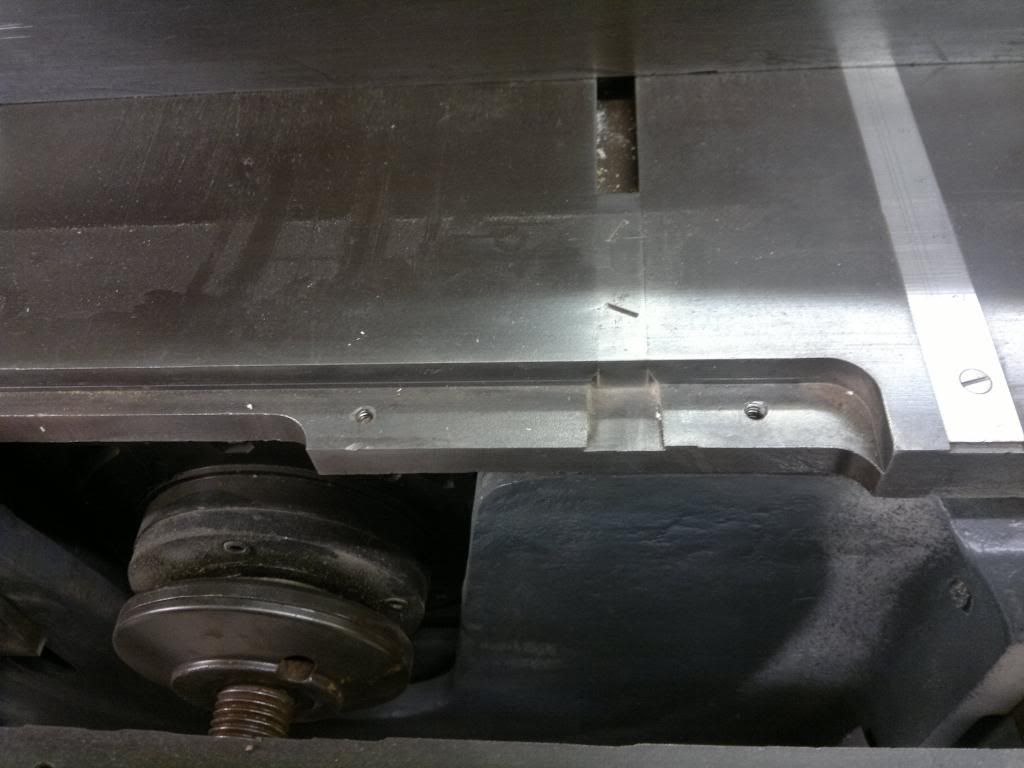

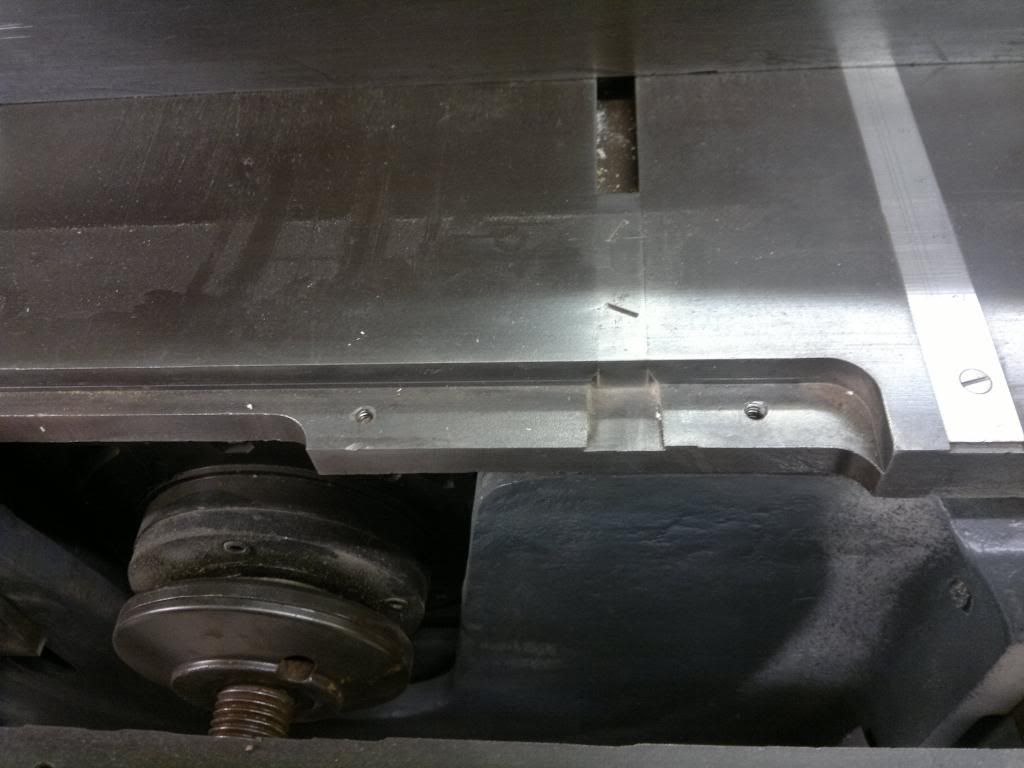

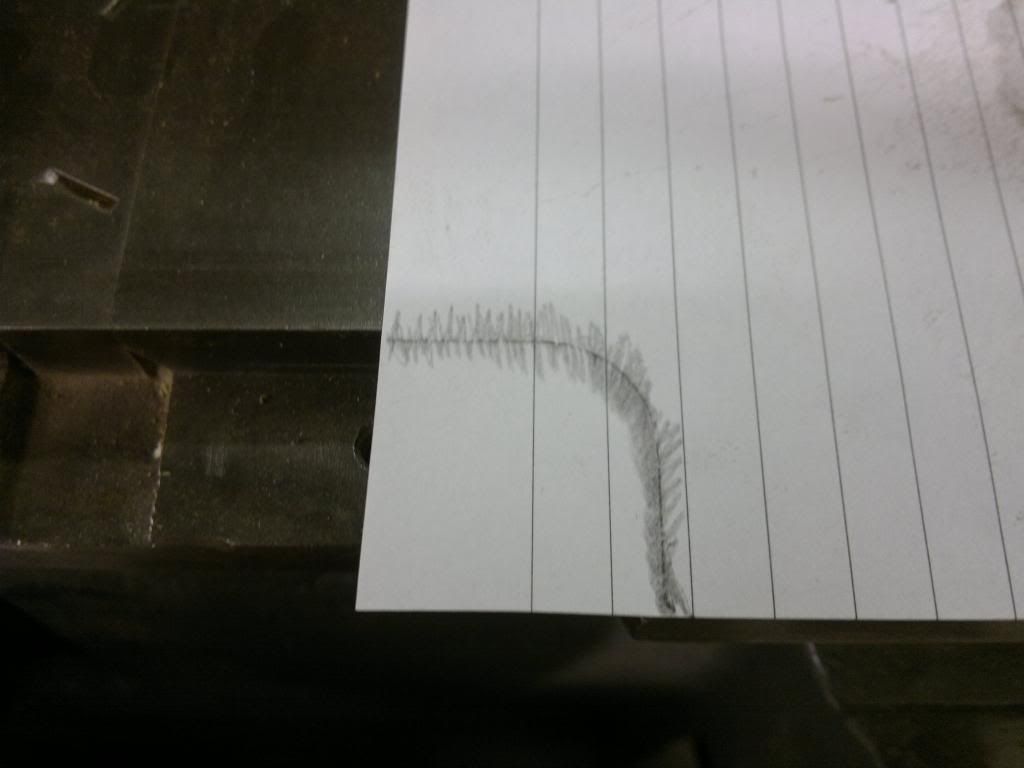

I thought I'd do a bit pimping out, instead of the normal wood inserts I got some brass flat bar.

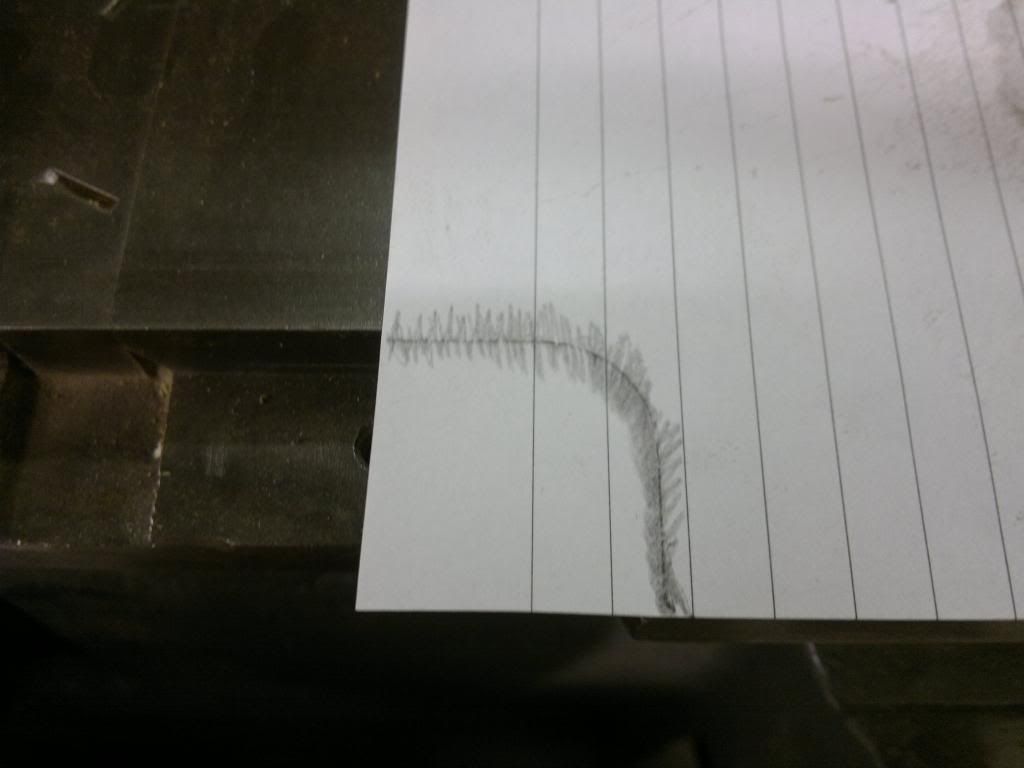

To make it fit nice and snug I traced the ends and then glued it onto the brass, then used a disc sander to sand to the line. I had to remove 3/4mm off the thickness.

To do the long edge I had to remove 1.5mm so instead of just sanding I used the router table. and then finished off by sanding.

To make it fit nice and snug I traced the ends and then glued it onto the brass, then used a disc sander to sand to the line. I had to remove 3/4mm off the thickness.

To do the long edge I had to remove 1.5mm so instead of just sanding I used the router table. and then finished off by sanding.