wallace

Established Member

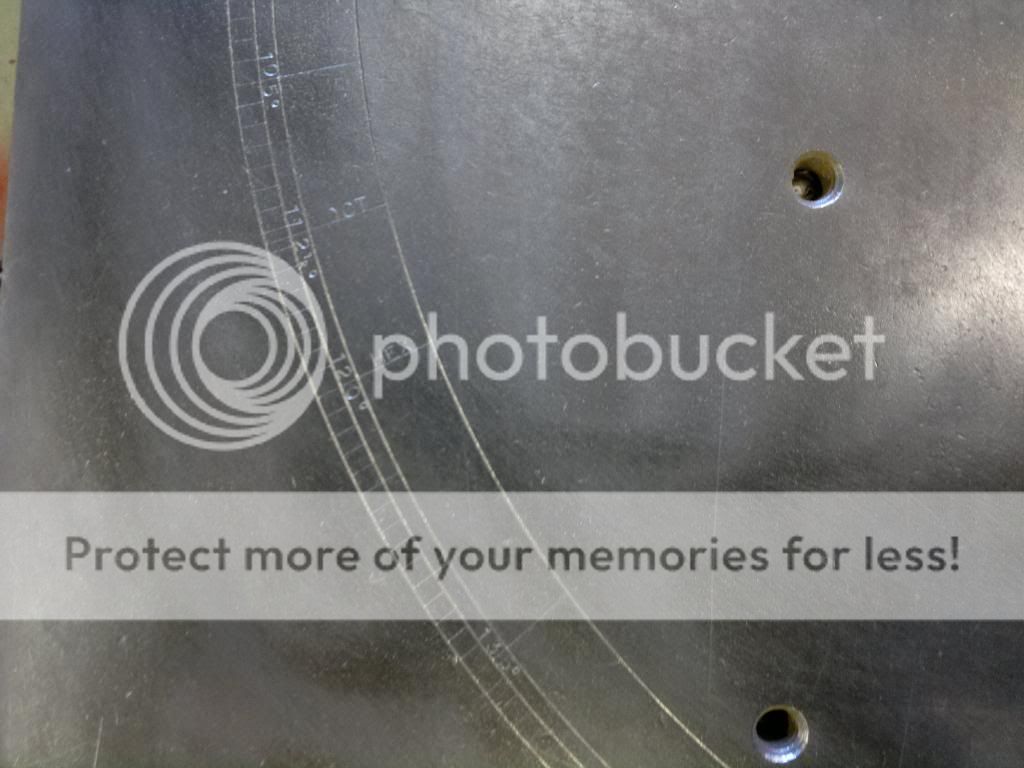

This crown guard support is from a standard sized pk, the one I have has an extension table so the length of round bar is not long enough. I thought the pin was going to be stuck in, but with a good wack with a punch it popped out.

Getting the bar out was a different story. I gave it a good soak with plus gas and heated it up but it would not come out. I got it to turn with the use of stilsons and a long extension. I tried using various pullers with no success

In the end I just chopped it off, before I busted the casting. I can change round bar easily but I cant replace a damaged casting.

I cleaned the end up and my plan is to use some quite nice bright bar I already had. This stuff cost £40 a length so I've been saving it for something decent. Its smaller diameter than the original so I'm going to get the piece that's stuck in the casting drilled and reamed to accept the smaller stuff.

Getting the bar out was a different story. I gave it a good soak with plus gas and heated it up but it would not come out. I got it to turn with the use of stilsons and a long extension. I tried using various pullers with no success

In the end I just chopped it off, before I busted the casting. I can change round bar easily but I cant replace a damaged casting.

I cleaned the end up and my plan is to use some quite nice bright bar I already had. This stuff cost £40 a length so I've been saving it for something decent. Its smaller diameter than the original so I'm going to get the piece that's stuck in the casting drilled and reamed to accept the smaller stuff.