You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

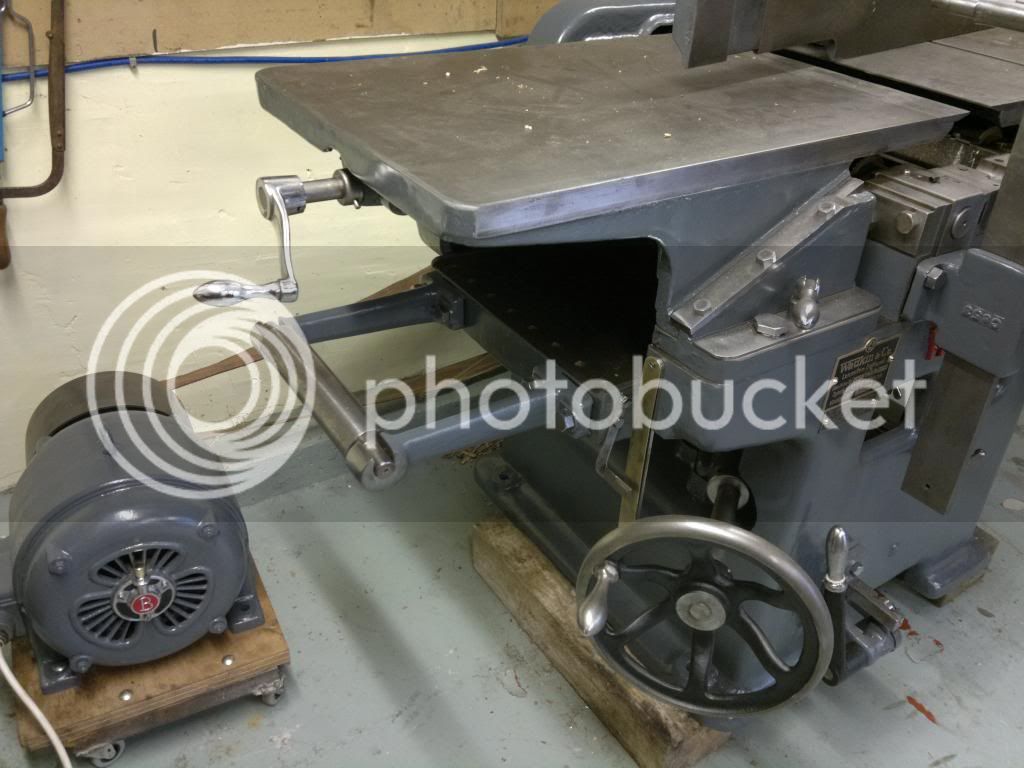

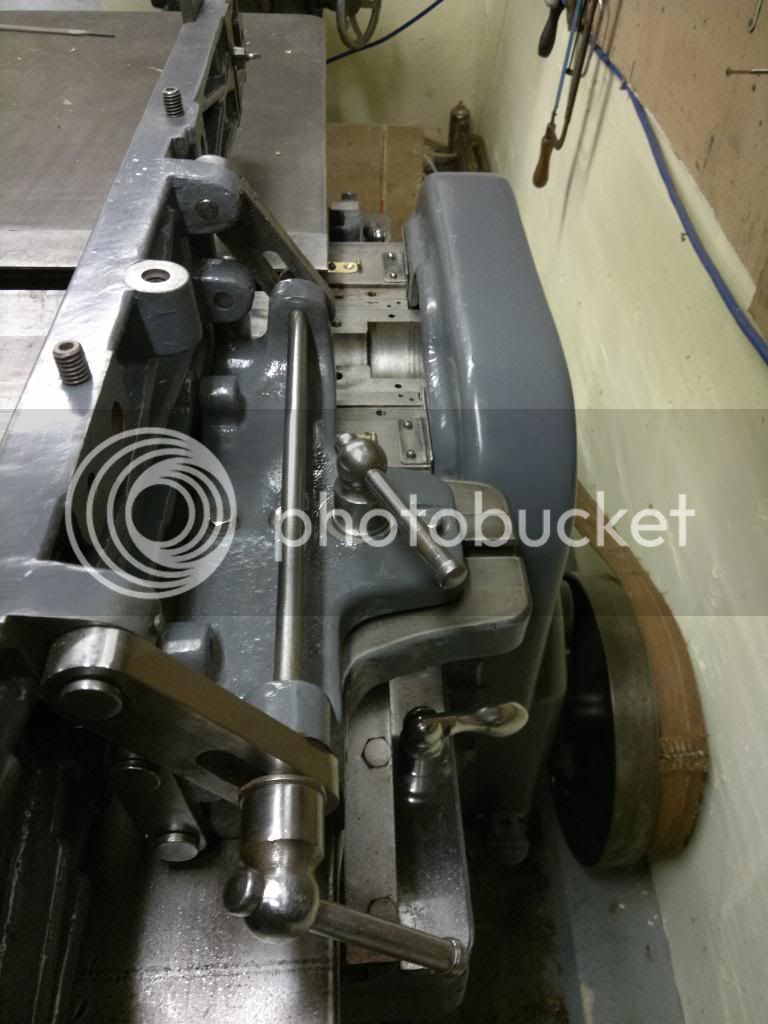

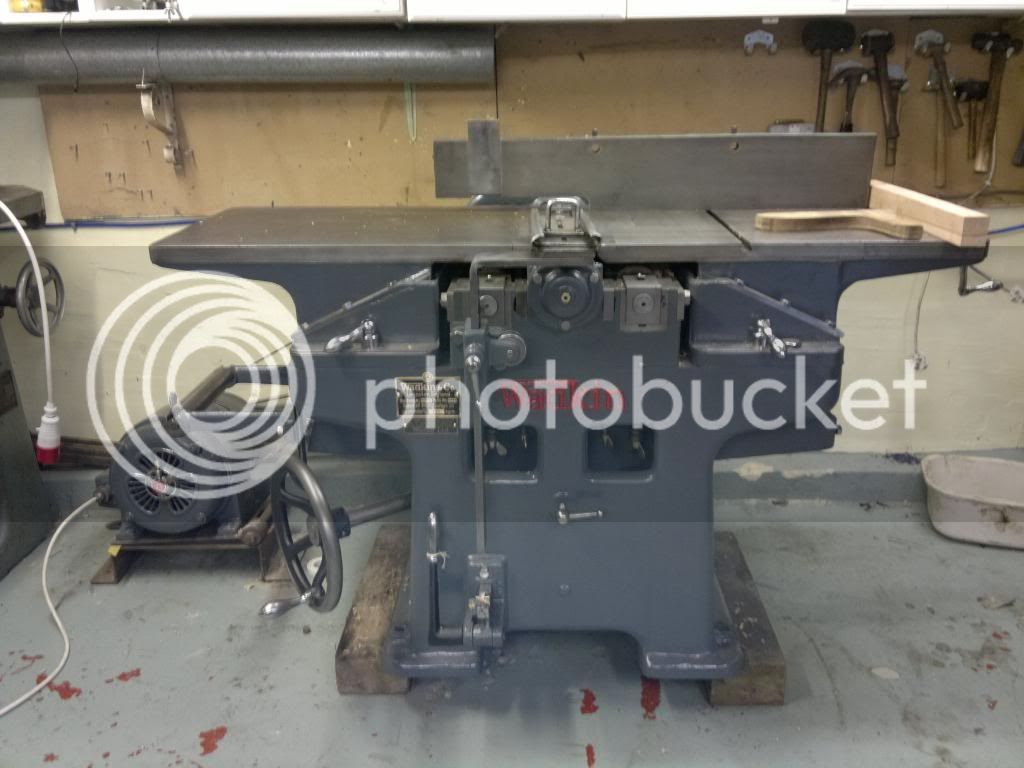

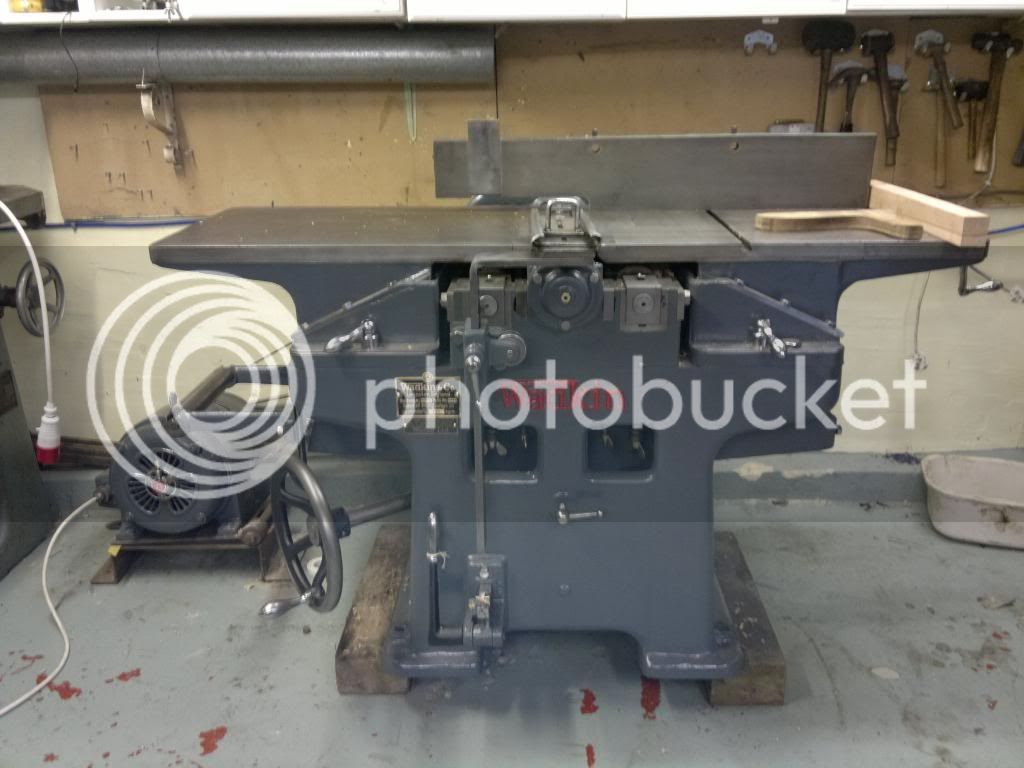

wadkin MJ restoration

- Thread starter wallace

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

Dangermouse

Established Member

- Joined

- 23 Dec 2010

- Messages

- 714

- Reaction score

- 0

All you need now is to build an extension !!

wallace

Established Member

I think I will be getting accused of running a business if I'm not careful. My workshop is already 17m long. My inlaws live next door to me and said I can extend into their garden.

You really amaze me - that MJ is probably better finished than when it left the factory.

Flynnwood

Established Member

wallace":1pdq1fkv said:My workshop is already 17m long. My inlaws live next door to me and said I can extend into their garden.

That's a yes then.

wallace

Established Member

I did a tally up of how many hours I have spent on this restoration. And it comes in at 95 hours, that's not exact and I still have the head to sort out.

nathandavies

Established Member

So at a modest £20/hr + machine.... i'll have to rethink my order for a pk. very nice work Wallace. What's next?

wallace

Established Member

I'd be happy with £10/hr  For my next trick I would like to do another pk, but I need to sell my completed one first. So if anyone wants an oversized pk in rather nice condition at a very reasonable price

For my next trick I would like to do another pk, but I need to sell my completed one first. So if anyone wants an oversized pk in rather nice condition at a very reasonable price

wallace

Established Member

Heres an update on the planer. The gearbox leek was sorted by gluing a modern oil seal to the outside of the casting. The head was a nightmare, I ended up drilling nearly to threads and then collapsing the old thread and then repairing the original thread with a chaser. I got a new stud made and a new nut. The nut was a different weight so I sanded some off until it weighed the same as its opposite.

Heres a clip of it running, 10 points to the first person who can tell me where I messed up http://youtu.be/x97LzTjHoC4

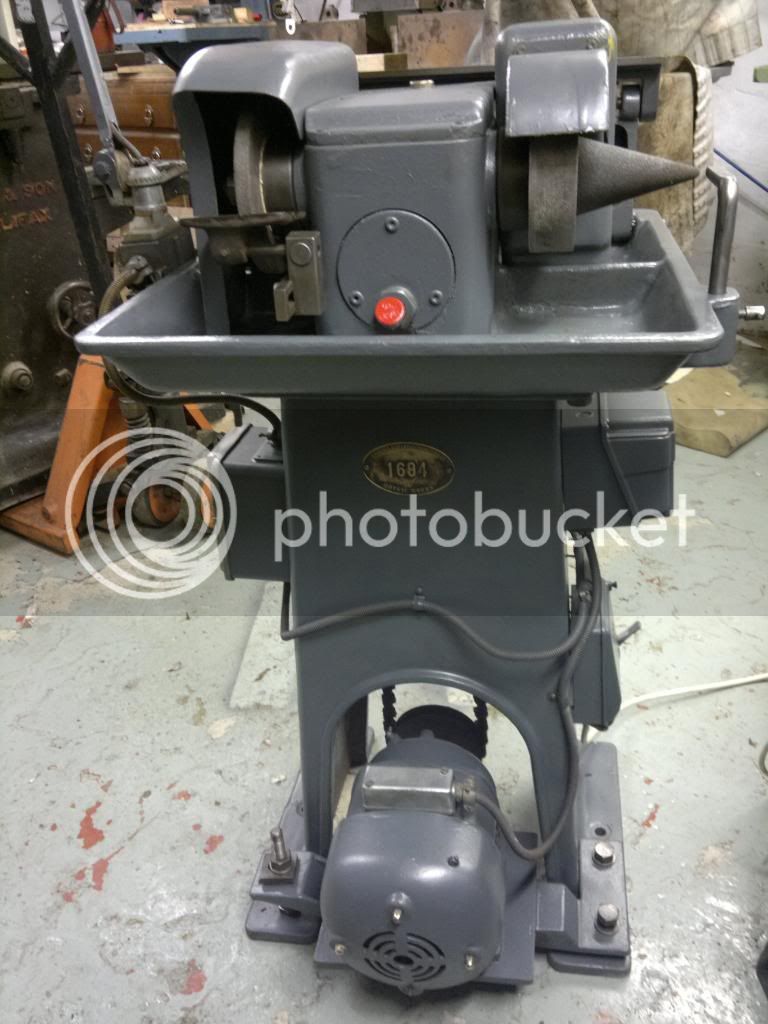

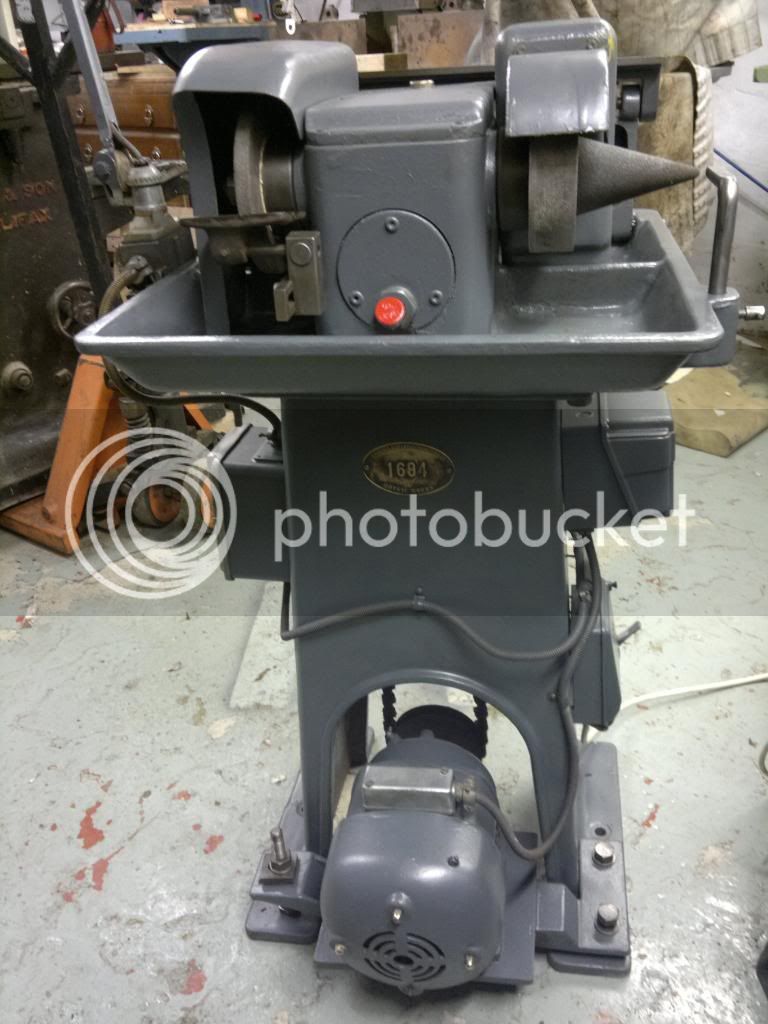

I also got that little Holroyd grinder done, It took me 7.5 hrs and made me £100

Heres a clip of it running, 10 points to the first person who can tell me where I messed up http://youtu.be/x97LzTjHoC4

I also got that little Holroyd grinder done, It took me 7.5 hrs and made me £100

Tony Spear

Established Member

Wallace - does the starter box on the little grinder have "Igranic" on it (can't be sure from the picture)?

wallace

Established Member

Yes Tony.

nathandavies

Established Member

just noticed the gothic tool works badge. I have a mummert Dixon grinder from the gothic tool works, it's in the queue (quite near the back)

wallace

Established Member

I have come to the conclusion that I'm not happy with the planer when running. I think its too loud and it just does not feel right. I'm going to take the cutter head back out and investigate further. I compared it to the j Sutcliffe planer and the difference is very noticeable

http://youtu.be/IClB6Wot6sQ

http://youtu.be/IClB6Wot6sQ

katellwood

Established Member

Wallace

Just a thought but when I turn the extraction on, on my felder the noise from the machine increases. I noticed that you have the bridge guards in place during your tests, on the Wadkin the whole cutter block appears to be covered with the bridge guard however on the second machine part of the cutter block is exposed behind the fence

Just a thought, maybe worth a try doing the test again without the bridge guards in place (but be careful)

Just a thought but when I turn the extraction on, on my felder the noise from the machine increases. I noticed that you have the bridge guards in place during your tests, on the Wadkin the whole cutter block appears to be covered with the bridge guard however on the second machine part of the cutter block is exposed behind the fence

Just a thought, maybe worth a try doing the test again without the bridge guards in place (but be careful)

Tony Spear

Established Member

wallace":3t2i3h49 said:Yes Tony.

Thought as much - Igranic were/are one of the leading switchgear manufacturers in the U.K.

A few miles up the road from me there's a reduntant/abandoned/derelict pumping station with Igranic switchgear and it's amazing!

I went to look at the station 20 years as they were looking at (yet again!) replacing the pumps and the old pumping station was still there.

All the cabinets were/are black enamelled steel, with rounded corners and chrome rimmed instruments! It's like something from Dr.Who!

Sorry to hi-jack your thread, I have a thing about pumping stations, but you can't bring home a thing like that and shove it in the corner of the workshop!

You can bet your life that someone will come along to say that he collects Igranic switchgear, or that he worked for Allen Gwynnes when that pump station was first built! :lol:

wallace

Established Member

Katellwood I got a similar response from Jack Forsberg. I thought I'd go round and check everything and I can feel play on the pulley side, if I try and lift the shaft there is definitely movement. Not good for something that size and weight spinning at 5000rpm :shock:

Tony you hijack away I love anything like that.

Tony you hijack away I love anything like that.

Hi Wallace, amazing restoration, I love how you get those old machines looking. You mentioned the PK for sale, do you have pictures and details plus a figure in mind? Rgds, Mark

Similar threads

- Replies

- 8

- Views

- 506