You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

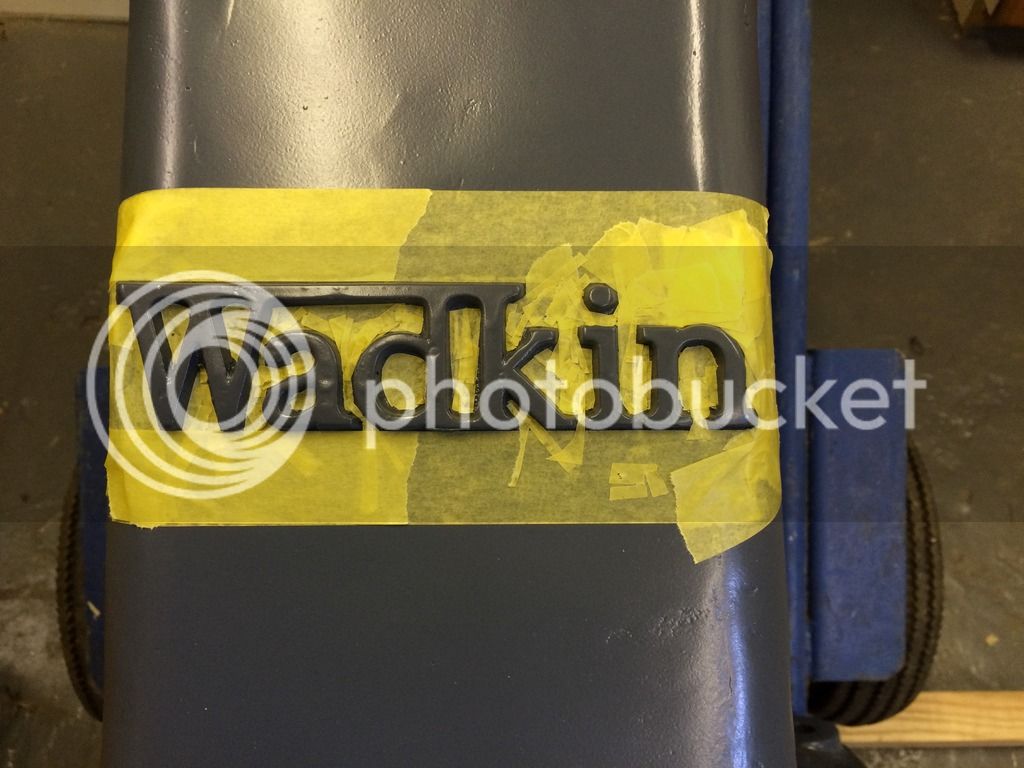

Wadkin mitre saw restoration

- Thread starter wallace

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I’m really enjoying this restoration! I’ve never restored a machine myself, but as I study mechanical engineering I have some knowledge of dynamics so may be able to answer the pulley diameter question. The only equation you need is v=wr, where v is tangential velocity, w (omega) is rotational velocity and r is the pulley radius. If you work in SI units v will be in m/s, w in rad/s and r in m.

You’ll need to know the maximum safe rpm of the blade, or rather the optimum rpm for cutting, and work backwards from that. If we take the maximum blade speed as 8000rpm, convert it to rad/s by multiplying by 2pi/60 (radians/rev * mins/sec), this gives a spindle rotational velocity of 838rad/s. For 83mm diameter spindle pulley, using v=wr this gives a belt velocity of 34.8m/s.

With the belt velocity, now just rearrange to give v/w=r, this time substituting in the motor speed rather than spindle speed. So the radius of the motor pulley you need is 34.8/298 = 0.117m (298 is 2850rpm in rad/s). Doubling you get motor pulley diameter 234mm. That will be the maximum diameter motor pulley you can have without exceeding 8000rpm blade speed. However, I just took a look at my tablesaw rating plate and its says rpm is 4700 yet the blade I have has maximum rpm of 8500, so perhaps optimum cutting speed is much less than maximum safe rotation speed.

All the above simplifies to:

Motor pulley diameter = (spindle speed / motor speed) * spindle pulley diameter. (you can use whatever units you like for spindle and motor speed as the cancel)

In hindsight I could have just written that at the top…

Forgive me if you already knew all this, I look forward to following more of this project as you progress.

You’ll need to know the maximum safe rpm of the blade, or rather the optimum rpm for cutting, and work backwards from that. If we take the maximum blade speed as 8000rpm, convert it to rad/s by multiplying by 2pi/60 (radians/rev * mins/sec), this gives a spindle rotational velocity of 838rad/s. For 83mm diameter spindle pulley, using v=wr this gives a belt velocity of 34.8m/s.

With the belt velocity, now just rearrange to give v/w=r, this time substituting in the motor speed rather than spindle speed. So the radius of the motor pulley you need is 34.8/298 = 0.117m (298 is 2850rpm in rad/s). Doubling you get motor pulley diameter 234mm. That will be the maximum diameter motor pulley you can have without exceeding 8000rpm blade speed. However, I just took a look at my tablesaw rating plate and its says rpm is 4700 yet the blade I have has maximum rpm of 8500, so perhaps optimum cutting speed is much less than maximum safe rotation speed.

All the above simplifies to:

Motor pulley diameter = (spindle speed / motor speed) * spindle pulley diameter. (you can use whatever units you like for spindle and motor speed as the cancel)

In hindsight I could have just written that at the top…

Forgive me if you already knew all this, I look forward to following more of this project as you progress.

wallace

Established Member

rbland :shock: I vaguely remember a little from O level physics so I can sort of understand that wonderful explanation. I had an idea of just going through the pulleys I have and see which works best, (homer) I have found one in my stash that is 130mm so will try that first.

wallace

Established Member

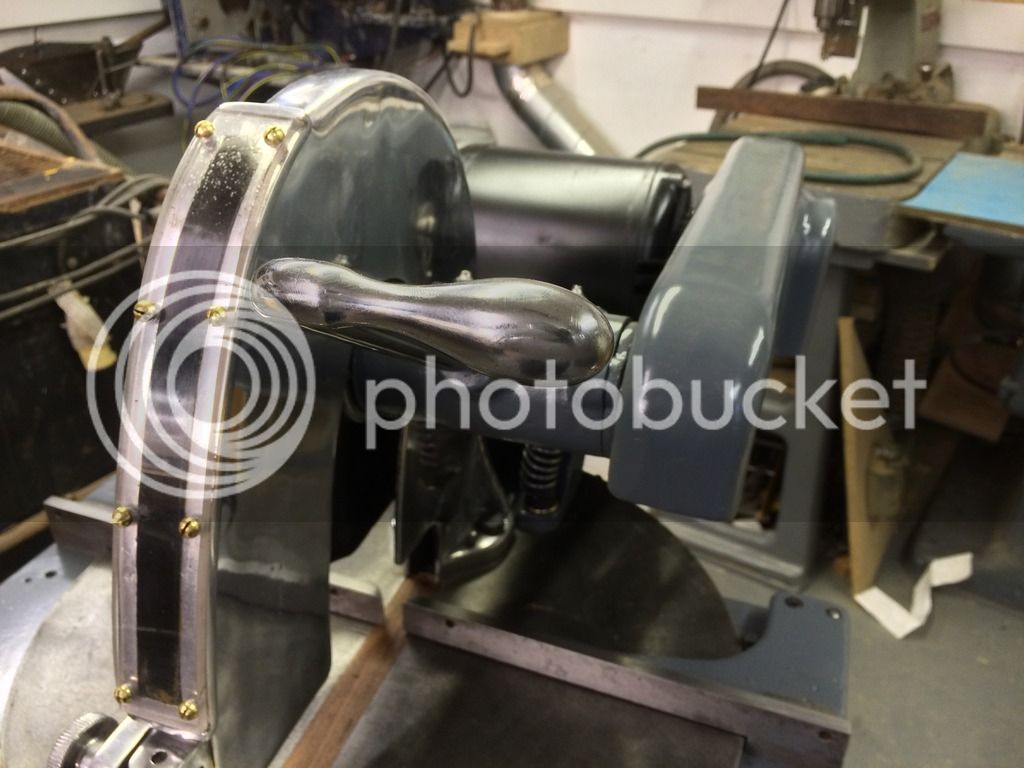

This was the little window into the blade guard.

I made a new one, one problem I had was the Perspex I was using was quite thick and I needed to heat it up quite a bit to achieve the bend. I ended up over doing it on a couple which causes bubbles to appear inside the stuff. In the end I just admitted defeat and will live with bubbles. I suspect my Perspex was too thick.

I had a bit of a drama with the enamel paint. I like it semi gloss but the paint guy didn't do it properly so I had to take it back and get it flattened. I then sprayed everything again and it was too shiny again. Strange thing was I gave a piece just a quick going over and it went the semi glass I wanted but where I'd laid down a few decent coats it was shiny when dry. Both sprayed at the same time. I've never experienced that before.

I wanted some brass washers so chopped rough shapes out drilled a hole and put them on the lathe.

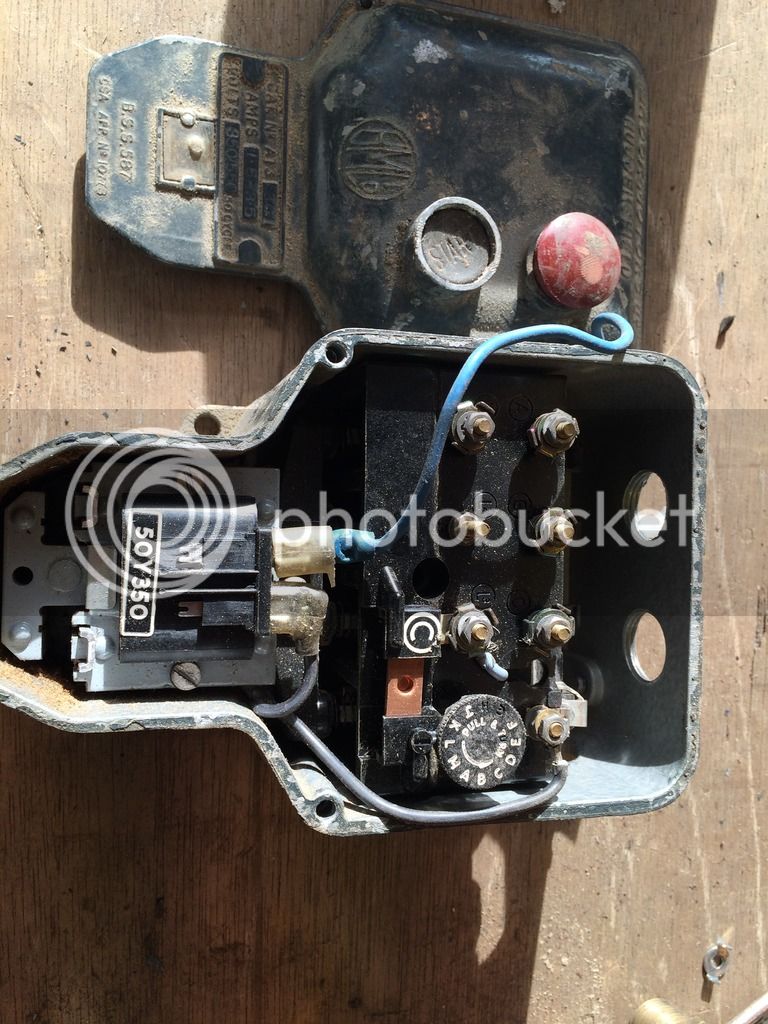

I need a starter for this saw as the one that came with it is fugly. I bought a new old stock starter a while back and thought it would look perfect on this. Gutted its only rated for less than 1A at full load.

I found this one in my stash which may work. I don't know what the blue wire is for can anyone give me a clue (Bob)

I made a new one, one problem I had was the Perspex I was using was quite thick and I needed to heat it up quite a bit to achieve the bend. I ended up over doing it on a couple which causes bubbles to appear inside the stuff. In the end I just admitted defeat and will live with bubbles. I suspect my Perspex was too thick.

I had a bit of a drama with the enamel paint. I like it semi gloss but the paint guy didn't do it properly so I had to take it back and get it flattened. I then sprayed everything again and it was too shiny again. Strange thing was I gave a piece just a quick going over and it went the semi glass I wanted but where I'd laid down a few decent coats it was shiny when dry. Both sprayed at the same time. I've never experienced that before.

I wanted some brass washers so chopped rough shapes out drilled a hole and put them on the lathe.

I need a starter for this saw as the one that came with it is fugly. I bought a new old stock starter a while back and thought it would look perfect on this. Gutted its only rated for less than 1A at full load.

I found this one in my stash which may work. I don't know what the blue wire is for can anyone give me a clue (Bob)

wallace

Established Member

wallace

Established Member

I sand them with wet and dry as little as possible to try and keep the raised lettering. Then spray with black from a rattle can, you can get a much thinner layer with rattle cans. Then wrap some wet and dry around a small piece of wood and remove the paint from the high spots. Very time consuming. The later wadkin cast tags are really easy because you can just paint and then flatten on sand paper glued to a board

Interesting page on saw speed here. The basic argument is that most cutting teeth work best at 150 ish linear feet per second. Used this when I put new pulleys on my table saw and it works great.

http://joneakes.com/jons-fixit-database ... ades-spin-

Edit: Doh forgot the link to the page!

http://joneakes.com/jons-fixit-database ... ades-spin-

Edit: Doh forgot the link to the page!

Random Orbital Bob

Established Member

Wallace for the Queen's honours list gets my vote!!............... Sir Wallace

You've done more to restore Britain's "Greatness" than Philip (Sir) Green and that's for sure!!!!

You've done more to restore Britain's "Greatness" than Philip (Sir) Green and that's for sure!!!!

Random Orbital Bob

Established Member

n0legs":228230vy said:I like that rub through on the stop button, makes it look like it's been used but cared for :lol:

Brilliant work Mark =D>

Dare I say "Shabby Chic"

I'll get me coat!

Too right Bob. Keep it up Wallace. Don't suppose I'll ever be able to justify owning a Wadkin so your posts are the closest I get. If I had one I have this idea I would probably talk to it. Rest my hand on it, just feel comforted a little by it's presence, reassured that though this life is fleeting it is given an anchor by the existence of quality above and beyond the necessary and the immediate. If you think about it.... actually, no don't think about it.Random Orbital Bob":36ch1onh said:Wallace for the Queen's honours list gets my vote!!............... Sir Wallace

You've done more to restore Britain's "Greatness" than Philip (Sir) Green and that's for sure!!!!

wallace

Established Member

That made me chuckle. You know wadkins are really quite cheap. This little lump cost £60 and another £45 for a courier, I've spent about £30 on paint, motor and stuff. So £135 for something that will outlive me

Not that my shop is turning into a man cave but I do have some nice pictures adorning my walls. This one has the same model planer that I have being hand finished in one of the bays at wadkin.

Weird thing is I used to have pictures of scantily clad pictures of woman on my walls as a kid now I have lumps of old iron.

Not that my shop is turning into a man cave but I do have some nice pictures adorning my walls. This one has the same model planer that I have being hand finished in one of the bays at wadkin.

Weird thing is I used to have pictures of scantily clad pictures of woman on my walls as a kid now I have lumps of old iron.

wallace

Established Member

Distinterior

Established Member

Fan-bloody-tastic job Wallace....!!!! That is a joy to behold!

You are a real inspiration to any one of us that is considering buying a potentially dead and buried old machine.

Well Done Sir!

You are a real inspiration to any one of us that is considering buying a potentially dead and buried old machine.

Well Done Sir!

wallace

Established Member

Thank you.

Wadkins don't die they just wait patiently to be resurrected

Wadkins don't die they just wait patiently to be resurrected

Now you have pictures of things you'd like to unscrew ... know the feeling well ...wallace":1ap48cwy said:That made me chuckle. You know wadkins are really quite cheap. This little lump cost £60 and another £45 for a courier, I've spent about £30 on paint, motor and stuff. So £135 for something that will outlive me

Not that my shop is turning into a man cave but I do have some nice pictures adorning my walls. This one has the same model planer that I have being hand finished in one of the bays at wadkin.

Weird thing is I used to have pictures of scantily clad pictures of woman on my walls as a kid now I have lumps of old iron.

Similar threads

- Replies

- 10

- Views

- 515

- Replies

- 1

- Views

- 514

- Replies

- 50

- Views

- 4K