wallace

Established Member

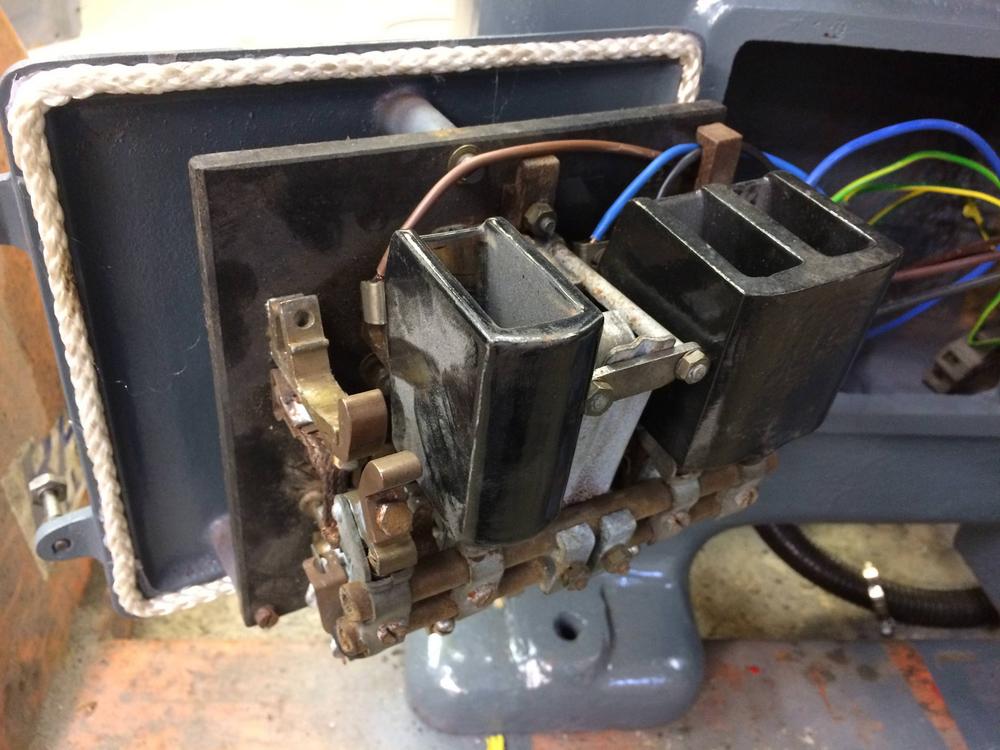

This is the bit I accidently broke when disassembling. I ground the edge but left enough to align the break.

A bit bronze snot

The other broken bit was a bit more complicated, so I drilled and tapped then removed the old repair

A bit bronze snot

The other broken bit was a bit more complicated, so I drilled and tapped then removed the old repair