Got the panels all raised today and the inside of the frame rounded over. Table saw used for all the panel raising. I now need to clean up all the panels, I did one today with a chisel and it took awhile. I think tomorrow I may use an old plane blade and have a go at making a molding plane to clean up the top chamfer on the panel. If it wasn't a bank holiday I may use this as an excellent excuse to buy

this.

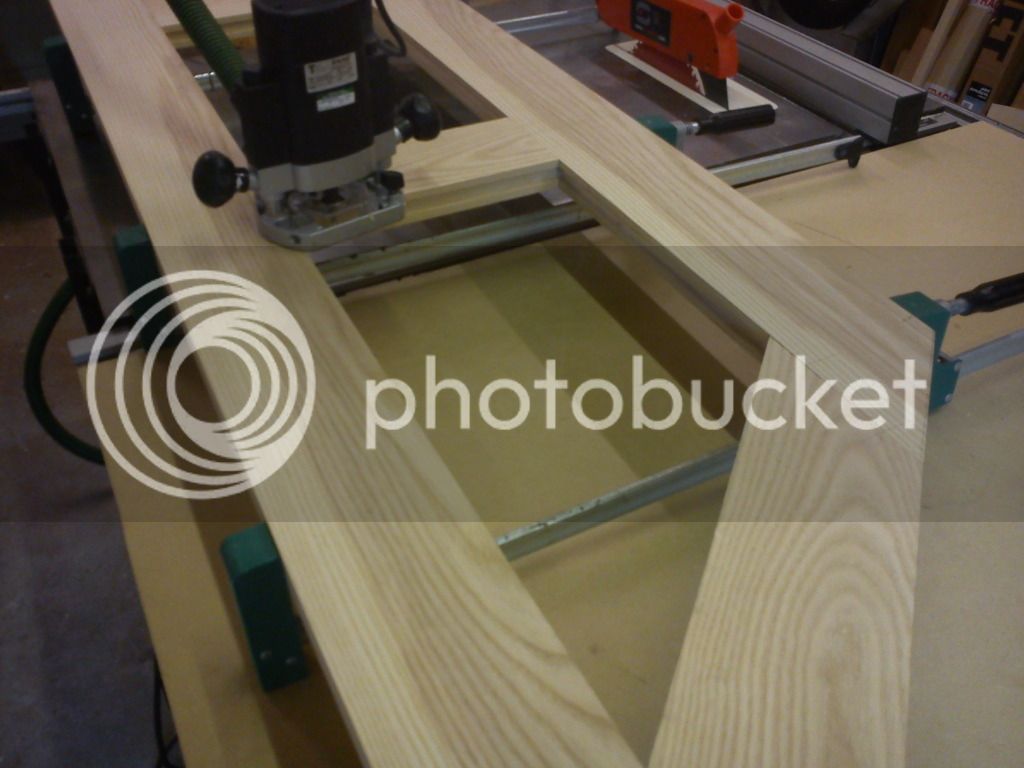

Rounding over the inside edge, I will have to square the corners by hand once its glued up.

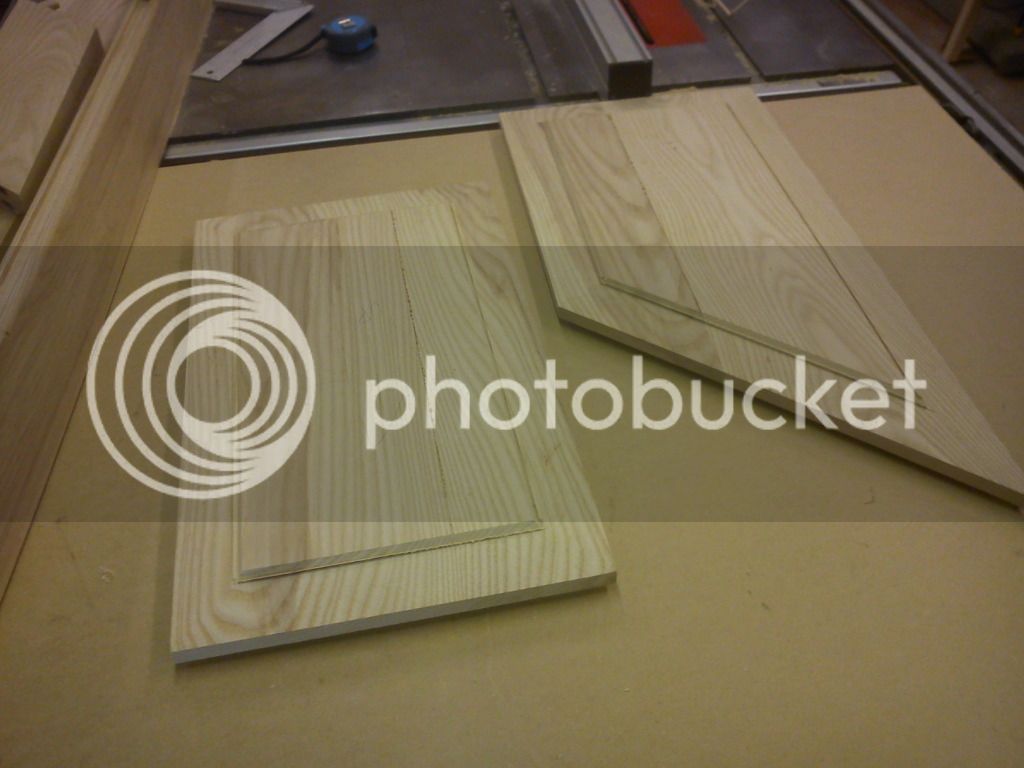

Sizing the panels and double checking the angle needed on the angled panel before cutting with CS and guide.

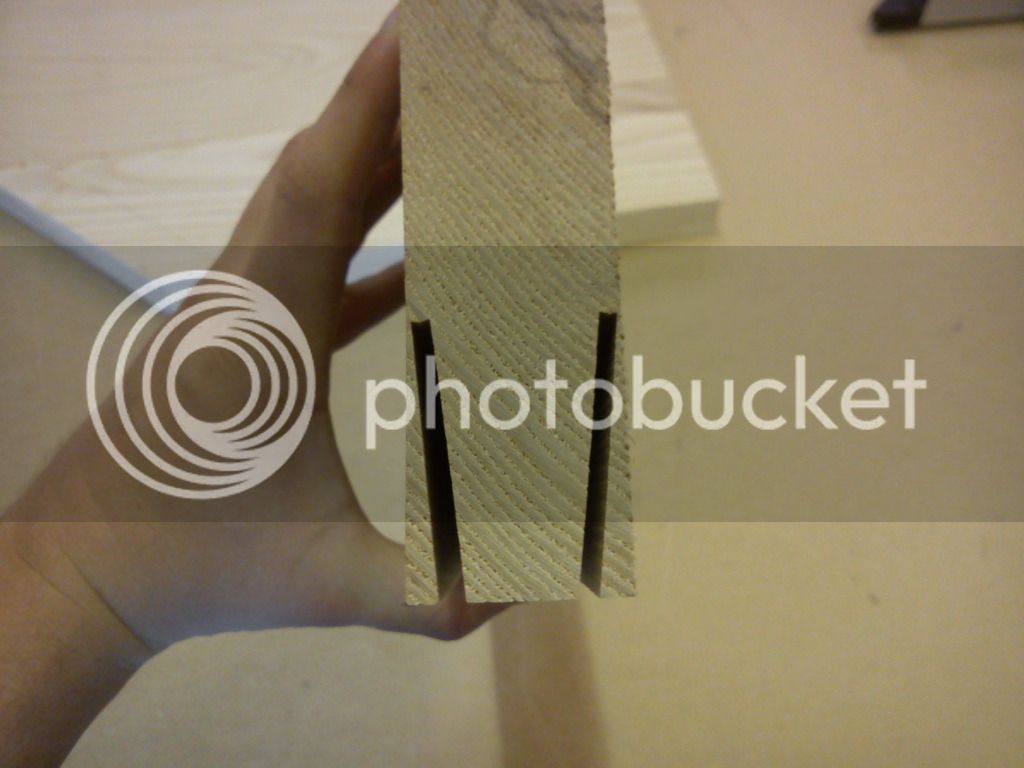

Trial run of panel raising, aiming to get a 8 degree cut with a little over 40mm deep chamfer.

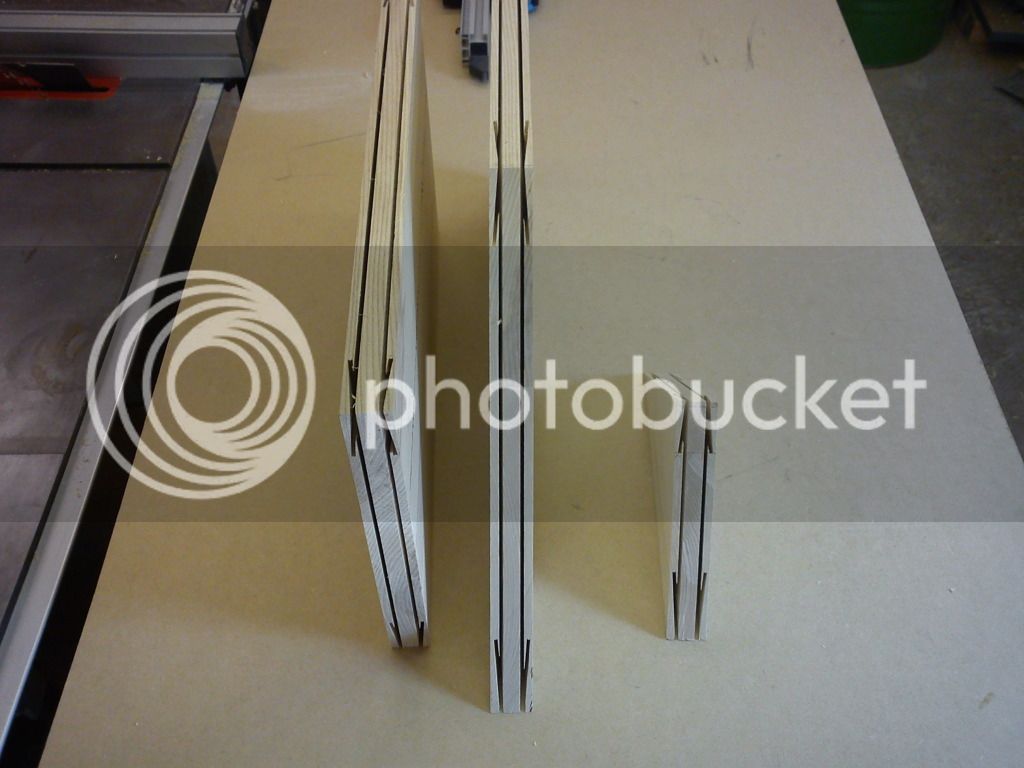

All cut.

Next they go through with the faces down and the saw at 90 degrees to just nibble away the last bit of material to reveal the raised panel.

Trial fit now the edges are down to 15mm to fit in the rebate.

Time to use the LN No4 to clean up the panel faces.

Slightly blurry this one, but a sort of finished panel.

Tomorrow may make this molding plane and get the doors glued up. Then just need to run off loads of tiny beading to go inside the frame and they'll be ready to fit and paint.