Firstly i would point out that if i were widening stock then i would be using loose tongues, biscuits, etc, etc, and not a cutter as depicted, the jointer provides a far truer edge than that of the spindle, but for flooring, then yes I would agree for flooring T&G the clearance makes a fair better job, and it makes perfect sense to provide clearance on the reverse, but then how many people bother to machine crowns down for flooring, a lot of people know no different.

I have used paired brazed blocks manufactured in this manner and the omas sets also are manufactured in a similar manner to provide clearance on one face so that the viewed side pulls up tightest

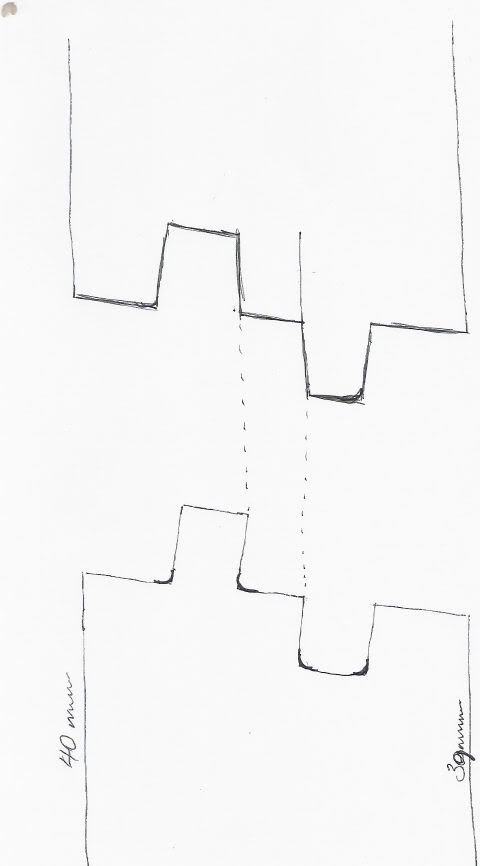

http://www.machines4wood.com/mall/popup ... ndsargeant Check out image3 and the resulting clearance on one face, ignore the way up the piece appears. This would be layed down with the clearance side down to the joist so resulting with a tight face. Leitz tooling

https://woodtechtooling.com/STARK/TH20F ... lesIN.html 2 of the biggest manufacturers. Note that joints can be made with the Leitz with tight faces both faces, but this is not the best method for flooring. The clearance is also there so that slight rises when layed over do not show on the top as gaps, and also it helps limit any squeaking from the bottom edges/tongue rubbing.

Omas and Leitz are not the only ones to do this and i have seen it on other industrial tooling.

Decorative T&G is a different matter, but by its nature of beads, v's, combinations of, then this is a different knife anyway, so i cannot see the link. I guess the question should be were the cutters ground with flooring etc, in mind. If so then i would agree with the method of the grind, if not then was it made clear that you wanted knifes ground for jointing up boards. If someone asked me for the same, if it were to be used for flooring i would have clearance on one side of the tongue for the points raised above. If for widening stock i would suggest other better methods, but then that is for the joiner to decide, not someone grinding the knifes.