pren

Established Member

Happy new Year's Eve, guys!

Figured I'd try and get one last project started before the decade's out.

Had my MiL ring me the other day, asking if I could make an art desk/table for her grandson who's birthday is in a week :shock: 'Right-ho' says I. 'I'll see what I can do'.

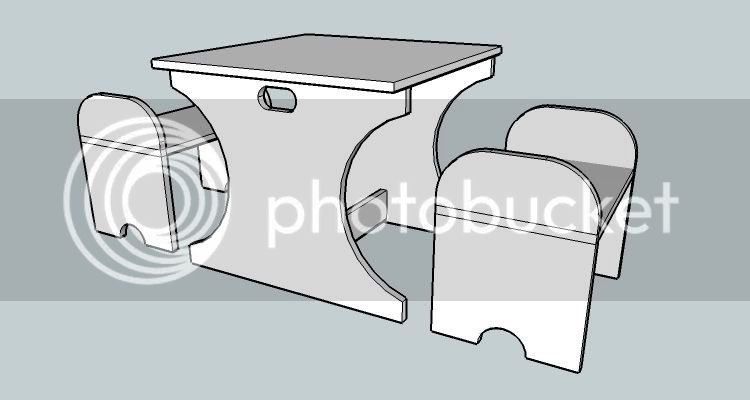

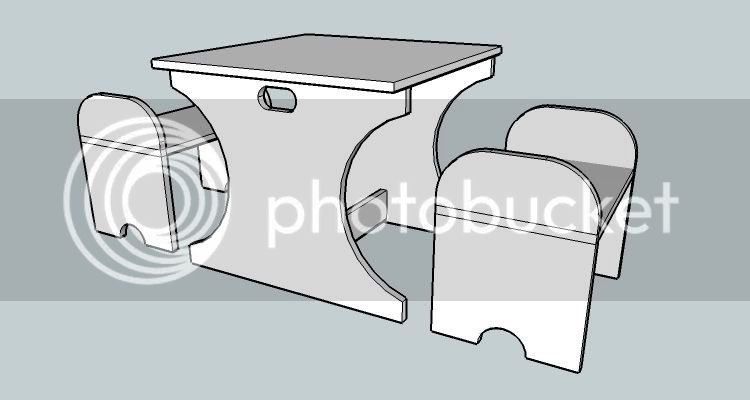

This is the design I came up with. Some of the aprons and stretchers are missing but will be on the finished artical.

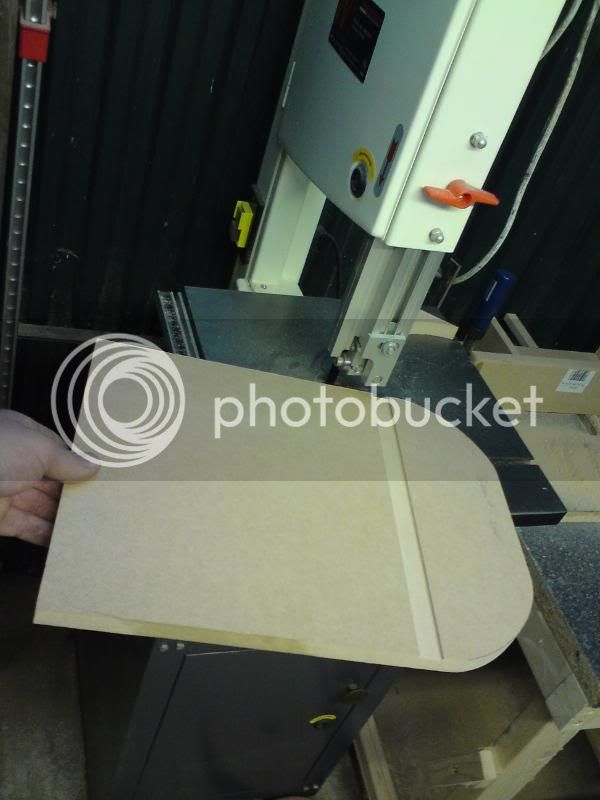

Luckily I had some 18mm MDF hanging around that was bought to make some doors for my never ending kitchen build so I decided to use it for this.

Afraid I didn't think to take any WiP's so far but this is the state of play so far (no joints have been made yet - clamps are just there to hold the whole thing up - they're not part of the final design :lol: )

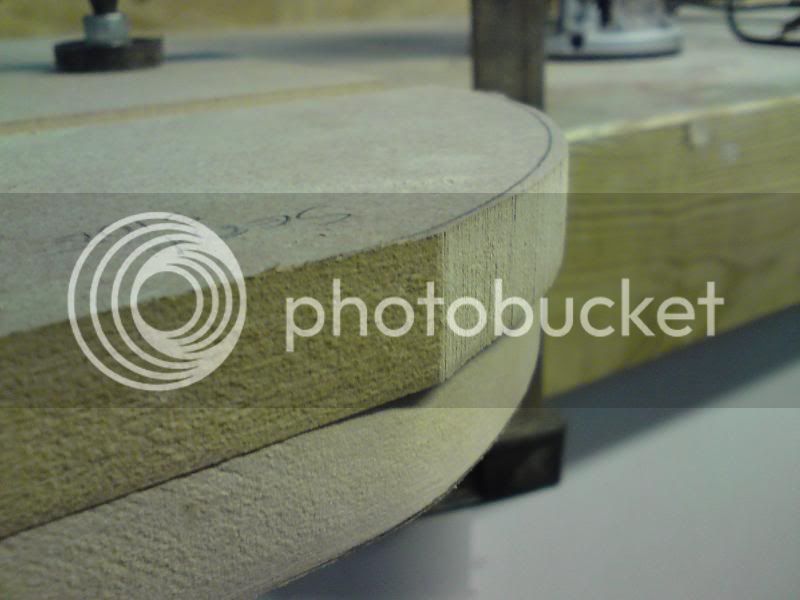

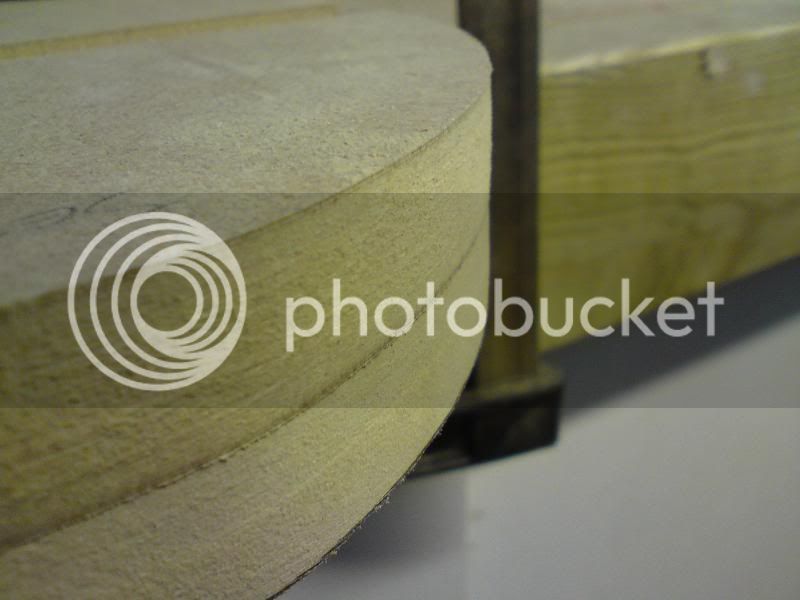

All the parts are cut to size and the semi-circles have been cut out using a router with a quickly made trammel and a jigsaw. The router was used to make a 5mm deep, semi-circular groove in in the MDF. The jigsaw was then used to cut away the waste, leaving a few mm of waste. A bearing guided trimming bit was then used to remove the waste, flush with the inner edge of the routed groove.

I hope to finish all the woodwork tomorrow as well as get as far as priming.

The joints for the desk and benches will be screwed housing joints and dowels supported by 50mm aprons under the desktop and seat board and 100mm stretchers between the 'legs' of both the desk and seats. These will be held with 8mm dowels and screws in pilot holes.

Does that sound ok?

Right. Beer O'Clock.

Figured I'd try and get one last project started before the decade's out.

Had my MiL ring me the other day, asking if I could make an art desk/table for her grandson who's birthday is in a week :shock: 'Right-ho' says I. 'I'll see what I can do'.

This is the design I came up with. Some of the aprons and stretchers are missing but will be on the finished artical.

Luckily I had some 18mm MDF hanging around that was bought to make some doors for my never ending kitchen build so I decided to use it for this.

Afraid I didn't think to take any WiP's so far but this is the state of play so far (no joints have been made yet - clamps are just there to hold the whole thing up - they're not part of the final design :lol: )

All the parts are cut to size and the semi-circles have been cut out using a router with a quickly made trammel and a jigsaw. The router was used to make a 5mm deep, semi-circular groove in in the MDF. The jigsaw was then used to cut away the waste, leaving a few mm of waste. A bearing guided trimming bit was then used to remove the waste, flush with the inner edge of the routed groove.

I hope to finish all the woodwork tomorrow as well as get as far as priming.

The joints for the desk and benches will be screwed housing joints and dowels supported by 50mm aprons under the desktop and seat board and 100mm stretchers between the 'legs' of both the desk and seats. These will be held with 8mm dowels and screws in pilot holes.

Does that sound ok?

Right. Beer O'Clock.