santiniuk

Established Member

Hi all,

Thought I'd share some of the work I was doing this week. I guess I have too many interests, one of them a couple of years back was 'homebrew' cnc machines.

To cut a long story short I spent a few month's designing a machine from scratch out of bit's I managed to scavenge from all over

What's this got to do with turning?

Well as a new addict to turning I used to hate sharpening, I was getting better at it but after seeing some video's of Jigs I looked around to see what was available. I hate buying things that I think are overpriced which I do feel a lot of the jigs on the market are.

So reading through the posts here I stumbled upon the fixtures that Chas had posted and thought I'd have a crack at making one. When I looked at my chisels I noticed the shafts were different sizes so I thought I'd rather make a few to save having to adjust and change plates etc.

So.... here's a few pic's.

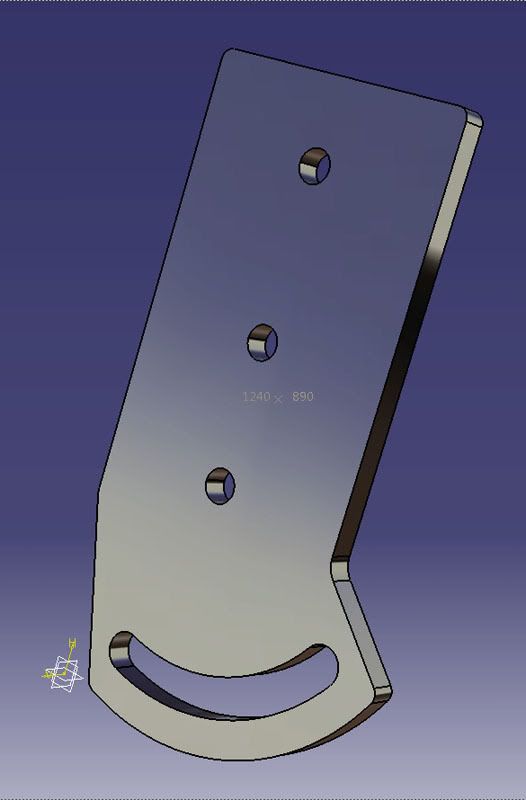

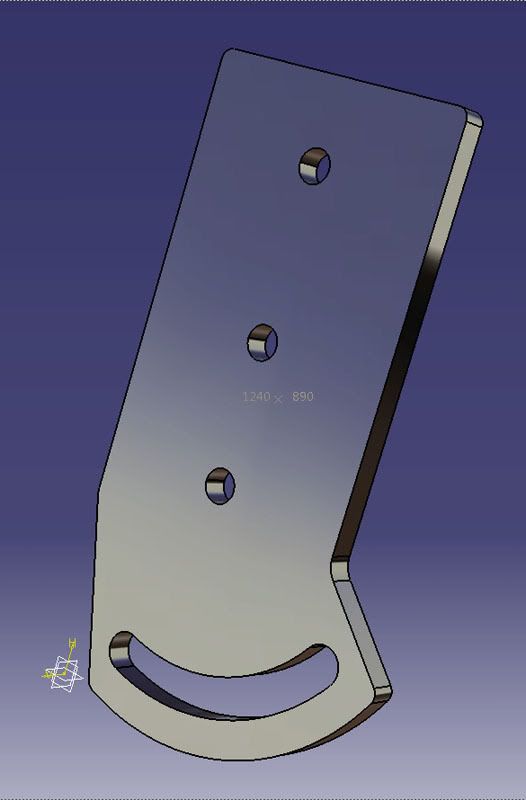

1. Taking the plans that Chas posted, I dropped the dimensions onto a cad program I use which gave me a 3D model of the plate. (About 10 mins to draw up)

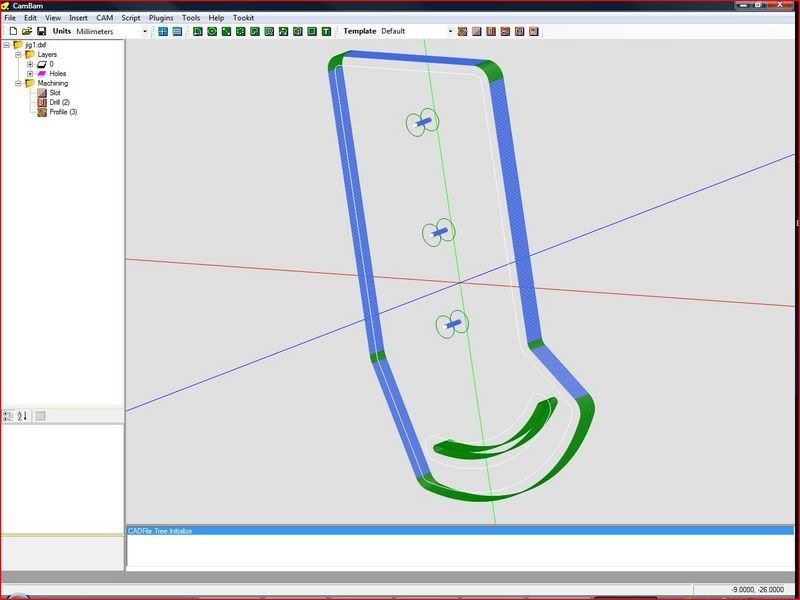

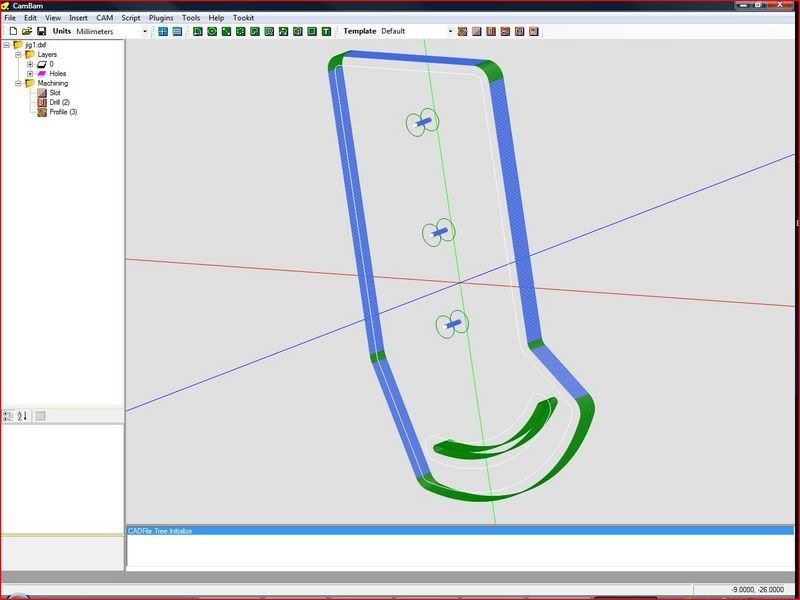

2. A good friend I know is writing a fantastic program called CAMBAM. It's still under development so I thought I'd use this to test it. This takes the 3d model and generates what is known as G-Code. This is the file that is used for the CNC. (about 10 mins to do code. I'm rusty so its more like a few mins)

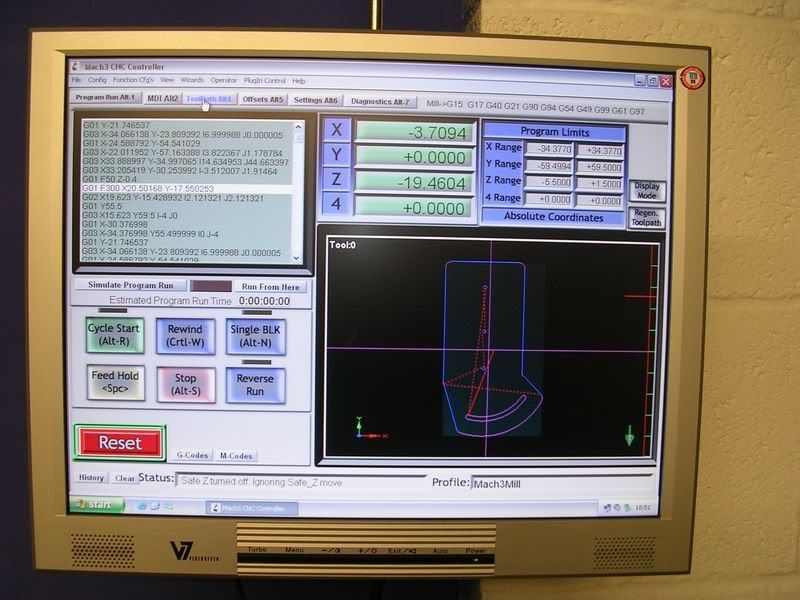

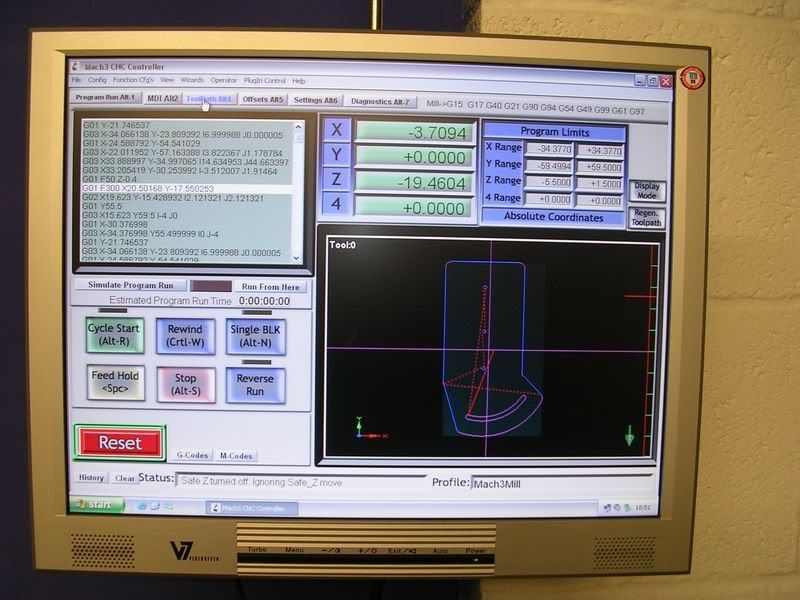

3. From Cambam the G-Code is loaded into a program called Mach III. This is a program I purchased that controls my 'homebrew' cnc.

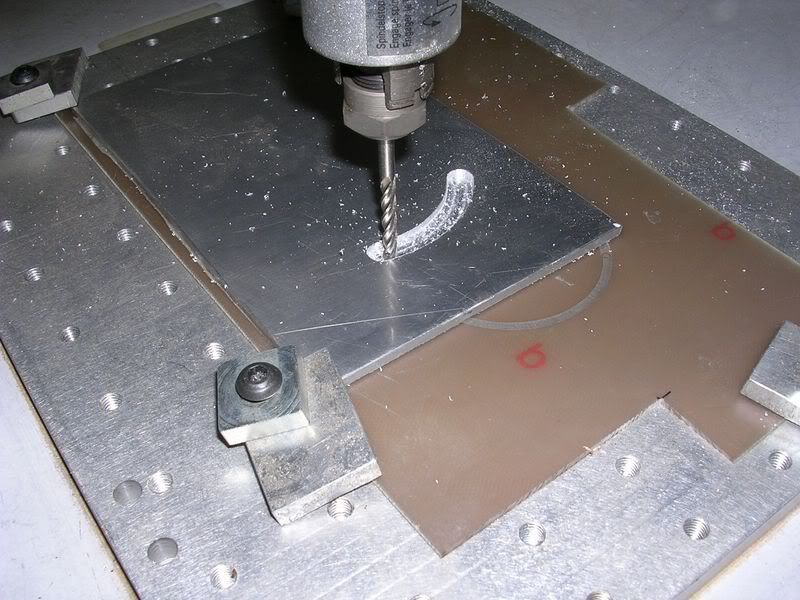

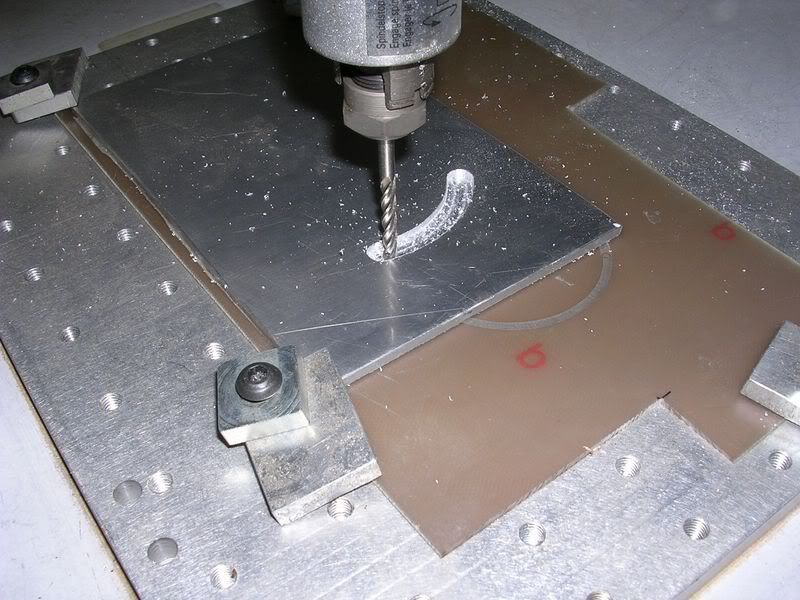

4. Here the fun begins. Using a 4mm cutter and some 4mm aluminium plate I had the machine sets away doing the automated cutting. (Cutting time about 10 mins)

I didn't fancy hand bashin that slot !

While the machine was cutting the plates I was turning the posts from Beech.

A bit of assembly and hunting for parts and all was complete. (Pics are before I had all the hardware for nuts, washers etc.)

So finally I cannot say how much easier this has made my life sharpening the tools. The simple jig works a treat.

Thanks very much for sharing these plans Chas. I'm in your debt ccasion5:

ccasion5:

Note: I may be accused of being lazy..... Your right

Cheers,

Shaun

Thought I'd share some of the work I was doing this week. I guess I have too many interests, one of them a couple of years back was 'homebrew' cnc machines.

To cut a long story short I spent a few month's designing a machine from scratch out of bit's I managed to scavenge from all over

What's this got to do with turning?

Well as a new addict to turning I used to hate sharpening, I was getting better at it but after seeing some video's of Jigs I looked around to see what was available. I hate buying things that I think are overpriced which I do feel a lot of the jigs on the market are.

So reading through the posts here I stumbled upon the fixtures that Chas had posted and thought I'd have a crack at making one. When I looked at my chisels I noticed the shafts were different sizes so I thought I'd rather make a few to save having to adjust and change plates etc.

So.... here's a few pic's.

1. Taking the plans that Chas posted, I dropped the dimensions onto a cad program I use which gave me a 3D model of the plate. (About 10 mins to draw up)

2. A good friend I know is writing a fantastic program called CAMBAM. It's still under development so I thought I'd use this to test it. This takes the 3d model and generates what is known as G-Code. This is the file that is used for the CNC. (about 10 mins to do code. I'm rusty so its more like a few mins)

3. From Cambam the G-Code is loaded into a program called Mach III. This is a program I purchased that controls my 'homebrew' cnc.

4. Here the fun begins. Using a 4mm cutter and some 4mm aluminium plate I had the machine sets away doing the automated cutting. (Cutting time about 10 mins)

I didn't fancy hand bashin that slot !

While the machine was cutting the plates I was turning the posts from Beech.

A bit of assembly and hunting for parts and all was complete. (Pics are before I had all the hardware for nuts, washers etc.)

So finally I cannot say how much easier this has made my life sharpening the tools. The simple jig works a treat.

Thanks very much for sharing these plans Chas. I'm in your debt

Note: I may be accused of being lazy..... Your right

Cheers,

Shaun