This has no doubt been covered before but I wondered if anyone highly rates a particular design of a "make your own" drill press station/fence?

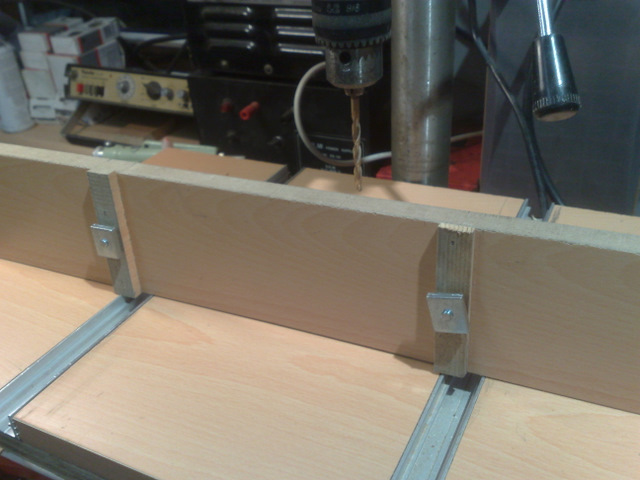

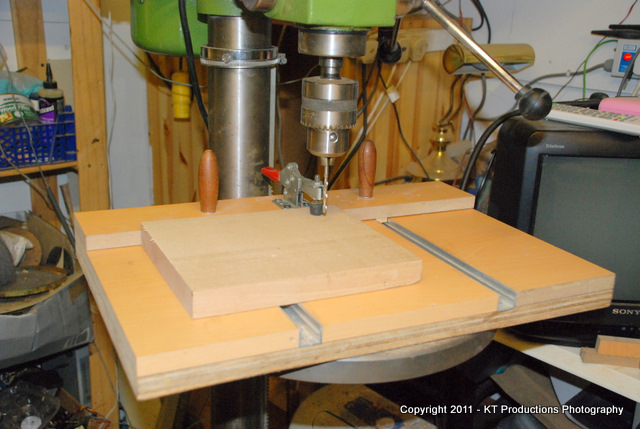

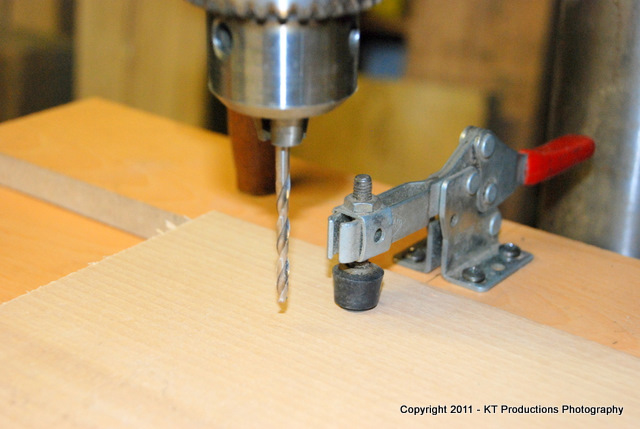

So basically just a platform of say MDF or other manmade material with adjustable fence(s) and clamping locations etc.

Does anyone know of any online free plans or can point me to a previous thread?

cheers

Steve

So basically just a platform of say MDF or other manmade material with adjustable fence(s) and clamping locations etc.

Does anyone know of any online free plans or can point me to a previous thread?

cheers

Steve