You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Terminating an electric cooker

- Thread starter DTR

- Start date

Help Support UKworkshop.co.uk:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

gav":1fli0pdd said:I believe soldering is not recommended for flex terminals as the soft solder can creep/cold flow and become loose on its own.

Gav

Sigh. Ok. So first I'm going to crimp it. After that I'm going to solder it. Then I'm going to drill a hole through it and pin it. Following that I'll superglue it. Then wrap some sellotape around it. As this is a woodwork forum, maybe I could squeeze a dovetail in there somewhere?

Actually stuff it, I'll just go back to a gas cooker.

Being serious though, we use several thousand soldered crimp connections where I work, all subject to vibration. I've seen untold of broken crimps and snapped cables through fatigue, but I've never once seen a failed solder joint.

Dee J

Established Member

The terminals are designed for flex, there is no need for crimp/solder/whatever. Not many places stock 6sq flex as 4 sq heat resistant is rated to 35Amps so is suitable for most domestic cooker situations. But there's plenty of cable on the internet http://essentialsupplies.co.uk/acatalog ... AhLG8P8HAQ

Of course you could do the usual bodge of T&E. See loads of cookers with this and haven't found any failed yet. But YMMV applies.

Dee

Of course you could do the usual bodge of T&E. See loads of cookers with this and haven't found any failed yet. But YMMV applies.

Dee

Dee J":27f66ucr said:See loads of cookers with this and haven't found any failed yet.

Dee

Me too, totally agree.

woodchip

Established Member

DTR":ezyw419f said:jolly1":ezyw419f said:Regarding calculating the load (amps) cable sizing should include the diversity factor, ie not likely all the load shall be in use at the same time. Should be 10 amps plus 5 amps if the cooker unit has socket plus 30% of the total load.

Interesting to know, thanks.

So... 11.3kW @ 240V = 47A

10A + 5A + (47A x 30%) = 29.125A

I think we should be using 220v not 240v which gives 30.4 a

230v surely?

Eric The Viking

Established Member

- Joined

- 19 Jan 2010

- Messages

- 6,599

- Reaction score

- 74

You could save the whole crimping thing - strip back enough to keep the lay and bend the bared strands into a Q shape, and tin that properly with solder. Voila! instant terminated end. Used to do it all the time when I wanted a tidy finish on big speaker connectors, etc..

Lons

Established Member

I've never seen flexi cable used for a cooker and see absolutely no need for it unless you're going to pull the cooker in and out every day. I've fitted well over a hundred kitchens some of which I've wired and some by an electrician where other work has involved him.

Mine is on 10mm T&E flat cable (commonly sold as cooker cable), it's a slot in full cooker comes out about once a month to clean behind and as good as the day it was put in. Was removed and re-installed a few years ago when I did the kitchen. Previous cookers for the past 40 years have been the same as are my kids appliances and pretty much everyone I know. Sounds way OTT to me.

Unless they've changed recently, cookers are intended to be wired under the supplied screws / serrated washers.

and I've yet to see an electrician crimp or solder the connections to one.

Just my two pennerth and could be wrong of course.

Bob

Mine is on 10mm T&E flat cable (commonly sold as cooker cable), it's a slot in full cooker comes out about once a month to clean behind and as good as the day it was put in. Was removed and re-installed a few years ago when I did the kitchen. Previous cookers for the past 40 years have been the same as are my kids appliances and pretty much everyone I know. Sounds way OTT to me.

Unless they've changed recently, cookers are intended to be wired under the supplied screws / serrated washers.

and I've yet to see an electrician crimp or solder the connections to one.

Just my two pennerth and could be wrong of course.

Bob

n0legs":1lme1k0y said:

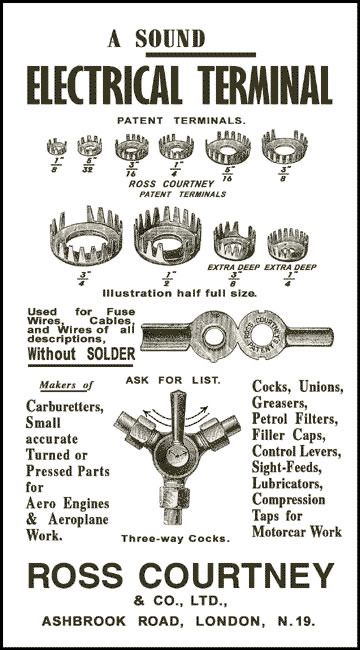

Funny you should post that, I keep a few Ross Courtney's in my tool bag at work for when I have to do an temporary fix on a broken crimp! They're probably more reliable than the crimps are!

misterfish

Established Member

One thing to also consider is warranty. We had a hob unit that included an extended warranty for 5 years cover that failed twice within the warranty period. After the second failure they replaced the hob with a new version and the repair engimeer told us to make sure we installed the new kit with the cable specified by the manufacturer (heat resistant 4mm flexible) as the warranty company were rejecting claims where installations were not fully compliant with the manufacturer requirements.

Mind you - the office staff of the warranty provider that AEG used initially were planning to replace our 60 cm electric hob with a much wider gas hob and it only took a couple of attempts to get them to supply a suitable bit of kit!

Misterfish

Mind you - the office staff of the warranty provider that AEG used initially were planning to replace our 60 cm electric hob with a much wider gas hob and it only took a couple of attempts to get them to supply a suitable bit of kit!

Misterfish

Sheffield Tony

Ghost of the disenchanted

DTR":8hmz08nv said:jolly1":8hmz08nv said:Regarding calculating the load (amps) cable sizing should include the diversity factor, ie not likely all the load shall be in use at the same time. Should be 10 amps plus 5 amps if the cooker unit has socket plus 30% of the total load.

Interesting to know, thanks.

So... 11.3kW @ 240V = 47A

10A + 5A + (47A x 30%) = 29.125A

Is this really what the regs say ? Amazing - makes no sense to me at all. It is not like intermittent duty or something like that - it is saying that if you turn all the rings on, the cable will be overloaded, but hey, you don't do that very often :shock:

This is rather like Fukushima logic. That sort of tsunami was a 1 in 1000 year event, so not worth worrying about. But wait a minute - the plant had been operating for 40 years, so the chance of a disaster having happened already was about 1 in 25. Unlikely things still happen.

jolly1

Established Member

Sheffield Tony":257i1uo2 said:DTR":257i1uo2 said:jolly1":257i1uo2 said:Regarding calculating the load (amps) cable sizing should include the diversity factor, ie not likely all the load shall be in use at the same time. Should be 10 amps plus 5 amps if the cooker unit has socket plus 30% of the total load.

Interesting to know, thanks.

So... 11.3kW @ 240V = 47A

10A + 5A + (47A x 30%) = 29.125A

Is this really what the regs say ? Amazing - makes no sense to me at all. It is not like intermittent duty or something like that - it is saying that if you turn all the rings on, the cable will be overloaded, but hey, you don't do that very often :shock:

This is rather like Fukushima logic. That sort of tsunami was a 1 in 1000 year event, so not worth worrying about. But wait a minute - the plant had been operating for 40 years, so the chance of a disaster having happened already was about 1 in 25. Unlikely things still happen.

Yes, that's exactly what the regulations state, do a search for cooker diversity factor

If you wish to test being amazed, how long will a 10 amp fuse take to blow, when carrying 20 amps

"This is rather like Fukushima logic. That sort of tsunami was a 1 in 1000 year event, so not worth worrying about. But wait a minute - the plant had been operating for 40 years, so the chance of a disaster having happened already was about 1 in 25. Unlikely things still happen."

No. No. No. The chance of disaster was 40 in a 1000. If the odds on winning the lottery are 14,000,000 to one, you don't make them 7,000,000 to one by buying two tickets. You have two chances in 14,000,000.

No. No. No. The chance of disaster was 40 in a 1000. If the odds on winning the lottery are 14,000,000 to one, you don't make them 7,000,000 to one by buying two tickets. You have two chances in 14,000,000.

jolly1

Established Member

phil.p":21616mf1 said:"This is rather like Fukushima logic. That sort of tsunami was a 1 in 1000 year event, so not worth worrying about. But wait a minute - the plant had been operating for 40 years, so the chance of a disaster having happened already was about 1 in 25. Unlikely things still happen."

No. No. No. The chance of disaster was 40 in a 1000. If the odds on winning the lottery are 14,000,000 to one, you don't make them 7,000,000 to one by buying two tickets. You have two chances in 14,000,000.

Diversity is applied in many cases without you realising. For example a ring circuit of sockets has 10 13 amp socket outlets, each capable of supplying 13 amps so by you logic, 10 x 13 amps = 130 (edit did me sum wrong) amps which would require something of the order of 35 mm squared, might be a wee bit difficult to get two of them in the socket terminations.

Current is not the only factor in specifying cable, aim of the calculation is to limit the volt drop , see IEE regulations, (I squared R losses)to 2.5% of the nominal voltage say 240Vac.

Your comment regarding Fukushima logic, is actually risk management. Time elapsing does not change the odds the odds remain the same. A simplistic view of 1 in a 1000 year event, odds of it happening today are 1000 x 365, or another method is to say 0.001% like I say it is a simplistic view

At it simplest level risk can be considered the odds of an event happening. If you wish to have 100% guarantee not to be knocked down by a car, then don't cross the road or walk beside a road. Aim of Risk management is to mitigate risk to an acceptable level, not eliminate them.

So in the end I crimped then soldered the flex terminations at the cooker, and insulated the crimp shanks(?) with heatshrink. Overkill probably, but rather that than worry about it not being good enough.

You lot have got me worried about my nuclear reactor now though

You lot have got me worried about my nuclear reactor now though

jolly1

Established Member

I would be more worried about the dreadful wind turbines

No skills

Established Member

DTR":2d0j3z9v said:You lot have got me worried about my nuclear reactor now though

I'd only worry about it if all the neighbours paddling pools burst at the same time in the summer. Haven't got pet lizards as well have you? Hmm... mini tsunami + small nuclear reactor + iguana = mini Godzilla?

Wheres the risk assessment chap gone?

DTR":32g58cw3 said:So in the end I crimped then soldered the flex terminations at the cooker, and insulated the crimp shanks(?) with heatshrink.

Nice one :wink:

Similar threads

- Replies

- 33

- Views

- 3K

- Replies

- 0

- Views

- 1K