Togalosh

Established Member

Hello Gents,

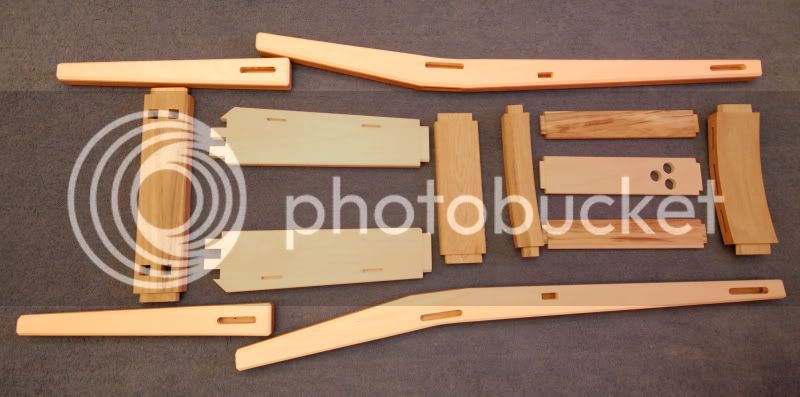

I scored a van load of old school science lab bench tops a while back & have now got round to making something from them but late in the day worked out that they are probably teak.. I've only worked with teak once before & that was 20 years ago & have a few questions. I am making a chest of drawers for CDs & the carcass is hopefully going to be dovetailed.

I have cut quite big, fairly evenly spaced dovetails but am worried about whether this is a good choice as the timber seems quite soft/crumbly..(but it's a bit late to ask !)

Should I use a different glue than the usual PVA?

Also the piece I made all those years ago started off dark green but has ended up matching the other orangey G-Plan furniture it is next to.. is there any way of keeping the fresh colouring (which is a very beautiful dark yellow) ?

Is there anything else I need to know about teak?

Thanks in advance

Togs

ps Hapy New Year !

I scored a van load of old school science lab bench tops a while back & have now got round to making something from them but late in the day worked out that they are probably teak.. I've only worked with teak once before & that was 20 years ago & have a few questions. I am making a chest of drawers for CDs & the carcass is hopefully going to be dovetailed.

I have cut quite big, fairly evenly spaced dovetails but am worried about whether this is a good choice as the timber seems quite soft/crumbly..(but it's a bit late to ask !)

Should I use a different glue than the usual PVA?

Also the piece I made all those years ago started off dark green but has ended up matching the other orangey G-Plan furniture it is next to.. is there any way of keeping the fresh colouring (which is a very beautiful dark yellow) ?

Is there anything else I need to know about teak?

Thanks in advance

Togs

ps Hapy New Year !