Peter G Denmark

Established Member

Ok - i thought i'd made a steal when i bought this saw for £170, but damn - this machine has got my number.

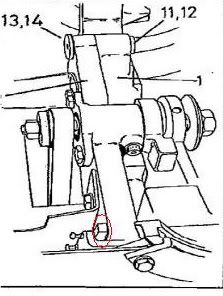

I thought i'd worked out all the problems but the rise and fall mechanism was very jagged. After 7 hours of fiddling i found out that there was a 0,2mm gap at the top between the slide bracket and the trunion assembly. When i tightned the set screw enough to take up this gap on what Wadkin refers to in the manual as the "motor bracket trapping piece" it actually held the rise and fall so tight it couldn't rise or fall anymore.

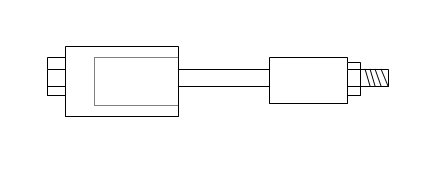

So now i've disassembed the whole motor mount again, and taken out the pivot pin for the slide bracket. I now found that the pivot pin has actually worn the brass bushing in the slide bracket, so it's loose by about 0,07mm (the 0,05mm feeler gauge could slide in and it still wasn't tight, but the 0,10mm couldn't slide in at all) which translates to a lot of deflection on the tip of a saw tooth.

I guess the pivot pin is what should hold the trunion and the side bracket parallel to each other, and the "motor bracket trapping piece" is only to make it snug - not to hold the whole weight of the motor, that puts on a massive outward pull.

Have any of you had the same problem and maybe found a solution? Is this the problem at all?

I've ordered some brass shim stock on eBay, but i'm a woodworker, not a machinist, so not sure if this will work?

This whole deal isn't made easier by the brilliant combination of metric and imperial measurements (the pivot pint and bushing is 3/4 inch). Not like you run to the nearest marked and pick up a selection of 3/4 inside diamenter bushing .

.

The £1000 Xcalibur saw looks better and better for each time this old timer saww spits in my face.

I thought i'd worked out all the problems but the rise and fall mechanism was very jagged. After 7 hours of fiddling i found out that there was a 0,2mm gap at the top between the slide bracket and the trunion assembly. When i tightned the set screw enough to take up this gap on what Wadkin refers to in the manual as the "motor bracket trapping piece" it actually held the rise and fall so tight it couldn't rise or fall anymore.

So now i've disassembed the whole motor mount again, and taken out the pivot pin for the slide bracket. I now found that the pivot pin has actually worn the brass bushing in the slide bracket, so it's loose by about 0,07mm (the 0,05mm feeler gauge could slide in and it still wasn't tight, but the 0,10mm couldn't slide in at all) which translates to a lot of deflection on the tip of a saw tooth.

I guess the pivot pin is what should hold the trunion and the side bracket parallel to each other, and the "motor bracket trapping piece" is only to make it snug - not to hold the whole weight of the motor, that puts on a massive outward pull.

Have any of you had the same problem and maybe found a solution? Is this the problem at all?

I've ordered some brass shim stock on eBay, but i'm a woodworker, not a machinist, so not sure if this will work?

This whole deal isn't made easier by the brilliant combination of metric and imperial measurements (the pivot pint and bushing is 3/4 inch). Not like you run to the nearest marked and pick up a selection of 3/4 inside diamenter bushing

The £1000 Xcalibur saw looks better and better for each time this old timer saww spits in my face.