gidon

Established Member

Well I mentioned this on another thread asking for advice on how to build a more heavy duty (work)shed - this ones just for storage (3m x 2.4m), so here are some pics:

Using a wedge to make a tight joint on the tongue and groove boards:

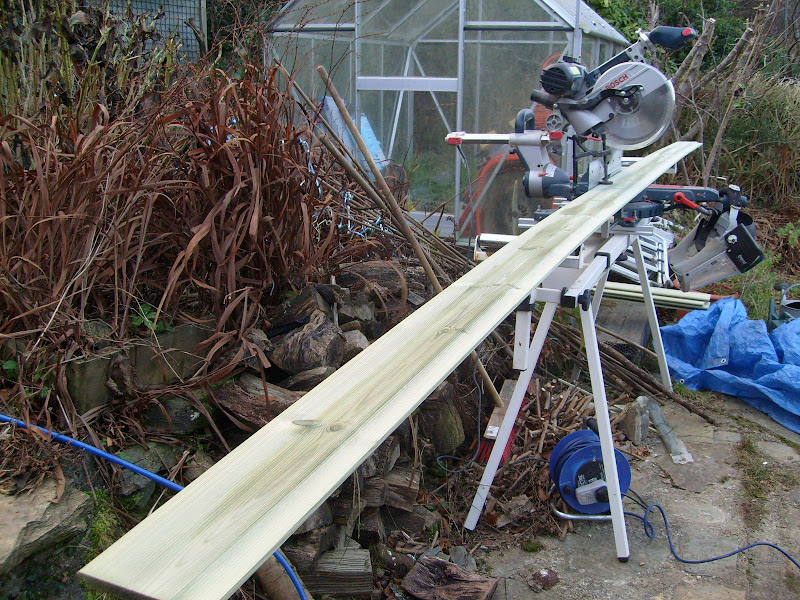

Framed the walls with pressure treated roofing battens ...

Full size drawing really helps for the roof - should have done something like this to start off with - had no plans at all not even a sketch which was stupid!

Ridge board held in place:

Cutting bird's mouth on rafters:

Roof framing done and some braces added.

I'm really not sure what I'm doing next - I might roof it or least get the OSB boards up.

Do you reckon it's worth adding any polythene sheeting for a storage shed? If so how do I do that? And I guess it's too late to bother with DPC - again didn't think it was necessary for this sort of shed.

Costs so far:

Floor joists, floor boards: £100 (B&Q)

Wall and roof framing timber: £100 (with a fair bit of 2x1 left over) (Tavistock Woodland Saw mill)

So considering cladding will be at least £200 and roofing probably £150 it's not cheap!

Any comments and suggestions always welcome.

Cheers

Gidon

Using a wedge to make a tight joint on the tongue and groove boards:

Framed the walls with pressure treated roofing battens ...

Full size drawing really helps for the roof - should have done something like this to start off with - had no plans at all not even a sketch which was stupid!

Ridge board held in place:

Cutting bird's mouth on rafters:

Roof framing done and some braces added.

I'm really not sure what I'm doing next - I might roof it or least get the OSB boards up.

Do you reckon it's worth adding any polythene sheeting for a storage shed? If so how do I do that? And I guess it's too late to bother with DPC - again didn't think it was necessary for this sort of shed.

Costs so far:

Floor joists, floor boards: £100 (B&Q)

Wall and roof framing timber: £100 (with a fair bit of 2x1 left over) (Tavistock Woodland Saw mill)

So considering cladding will be at least £200 and roofing probably £150 it's not cheap!

Any comments and suggestions always welcome.

Cheers

Gidon