tool613

Established Member

Hi boys its jack from Canada looking for your expertise. got a few question on some English kits.

How many mortiser can you fit in your trailer and not be over loaded? in my case 2.

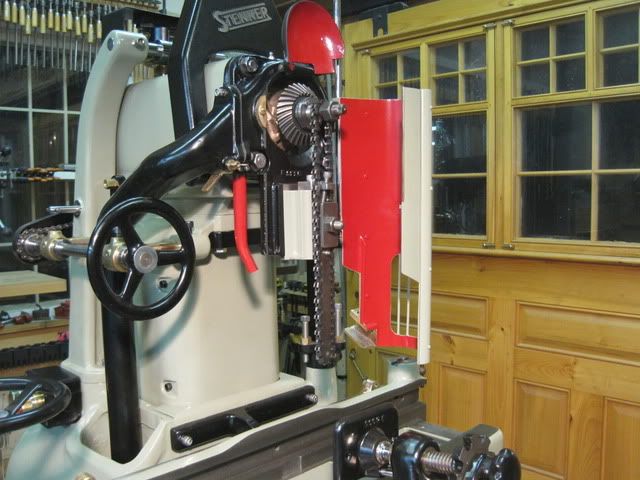

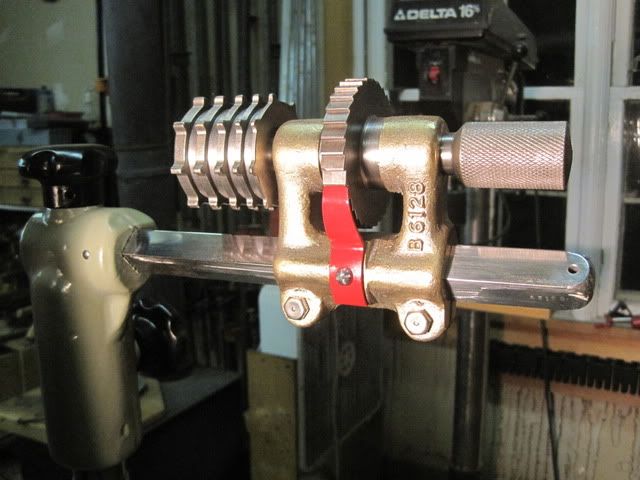

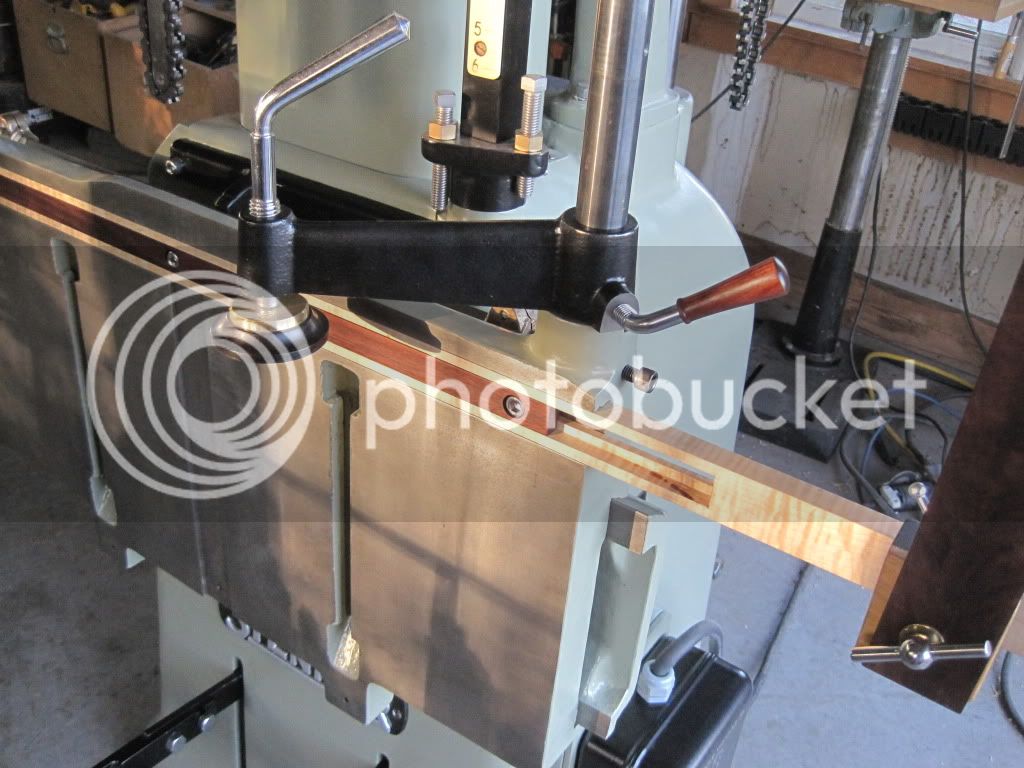

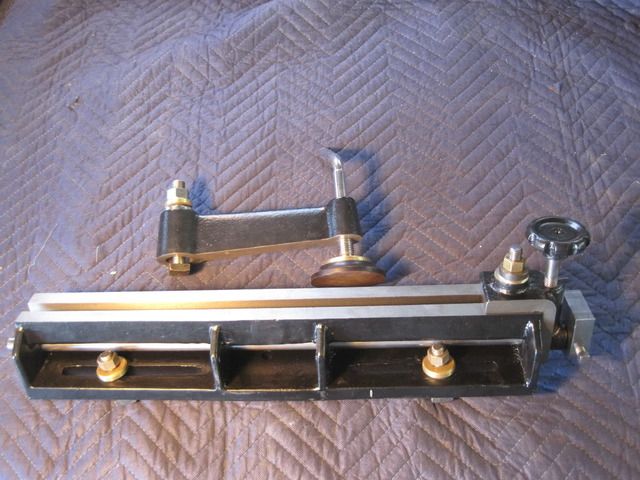

I picked these up a few days ago.Got the wadkin MF (lots of information on that one at Wadkin), the grand daddy king of all mortisers. The Stenner BL that i also picked up has heads that swap out from chain to chisel so it a combo machine too. I have never to date not found a machines i could not find any information on(Stenner that is ) before this .

can you boys help with this maker(Stenner) . I know they make pit re saws, but what other machines?

I can not even find a pic of the stenner BL motiser. Are there any owners? I need a manual or anything. Waiting with bated breath.

.

sorry that i do not have many of the STENNER .

jack

How many mortiser can you fit in your trailer and not be over loaded? in my case 2.

I picked these up a few days ago.Got the wadkin MF (lots of information on that one at Wadkin), the grand daddy king of all mortisers. The Stenner BL that i also picked up has heads that swap out from chain to chisel so it a combo machine too. I have never to date not found a machines i could not find any information on(Stenner that is ) before this .

can you boys help with this maker(Stenner) . I know they make pit re saws, but what other machines?

I can not even find a pic of the stenner BL motiser. Are there any owners? I need a manual or anything. Waiting with bated breath.

.

sorry that i do not have many of the STENNER .

jack