TimothyClaypole

Established Member

I'm currently excavating to hopefully build a garage/workshop.

Being thrifty I refuse to pay for skips so the company can charge me for them then sell the soil I put in them as well. So I have gone the recycling/Freecycle route and set out to sieve the lot then I can offer it as sieved, bagged soil.

It's a mixed bag of soil, sub soil, and a nasty sandstone mix where the 50's garage base originally was. The back gardens of mine and the two neighbours were raised for some reason, probably some excess soil when they were built. So I'm going down to the same level as my neighbour to the left as he has dug his garden out in the past. So by sieving it I end up with a sandy mixture rather than rubbish no one wants.

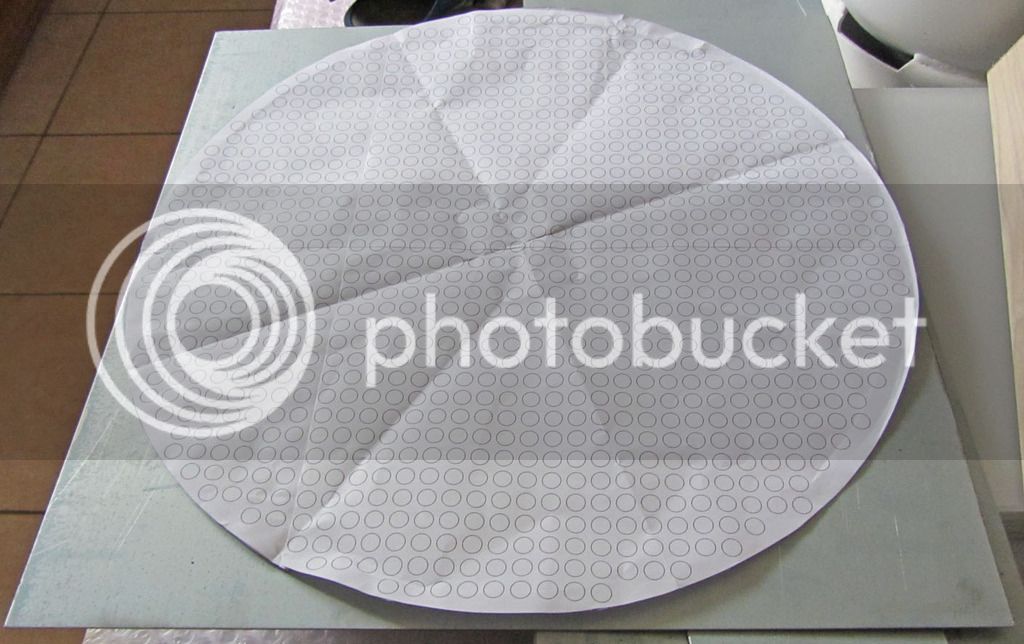

I'm on my second sieve as the wire on the first wore out due to Machine Mart selling it for compost not sandstone. :mrgreen:

But this one is heading the same way due to not enough welds and the thin wire is a nightmare to weld back with my terrible welding skills.

Does anyone know any heavier grade steel mesh that I could weld into the 1st sieve as a sturdier replacement?

I had a trawl on Ebay but most looks to be stainless steel.

Being thrifty I refuse to pay for skips so the company can charge me for them then sell the soil I put in them as well. So I have gone the recycling/Freecycle route and set out to sieve the lot then I can offer it as sieved, bagged soil.

It's a mixed bag of soil, sub soil, and a nasty sandstone mix where the 50's garage base originally was. The back gardens of mine and the two neighbours were raised for some reason, probably some excess soil when they were built. So I'm going down to the same level as my neighbour to the left as he has dug his garden out in the past. So by sieving it I end up with a sandy mixture rather than rubbish no one wants.

I'm on my second sieve as the wire on the first wore out due to Machine Mart selling it for compost not sandstone. :mrgreen:

But this one is heading the same way due to not enough welds and the thin wire is a nightmare to weld back with my terrible welding skills.

Does anyone know any heavier grade steel mesh that I could weld into the 1st sieve as a sturdier replacement?

I had a trawl on Ebay but most looks to be stainless steel.